QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 1 of 54

Appendix D

Measurement Quality Objectives and Validation Templates

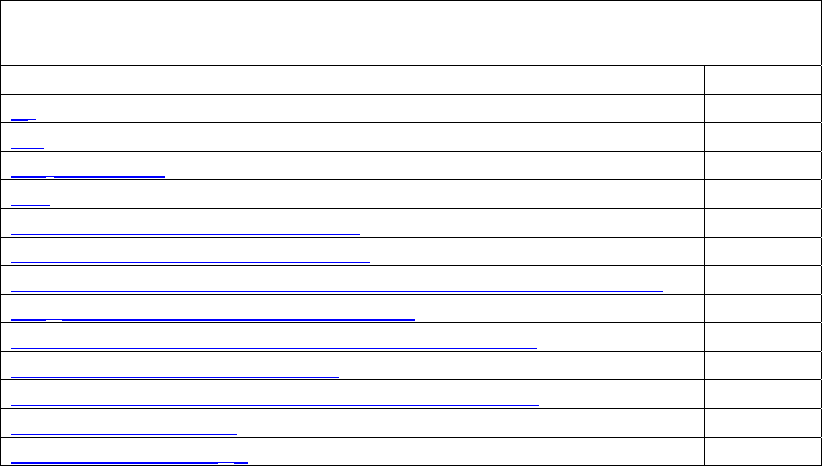

Table of Contents

(click on link to go to individual tables)

Validation Template Page

O

3

5

CO 8

NO

2

, NOx, NO 10

SO

2

13

PM

2.5

Filter Based Local Conditions 16

Continuous PM2.5 Local Conditions 21

PM10c for PM

10-2.5

Low –Volume , Filter-Based Local Conditions 25

PM

10

Filter Based Dichot STP Conditions 30

PM

10

Filter Based High Volume (HV) STP Conditions 33

Continuos PM10 STP Conditions 36

PM

10

Low Volume STP Filter-Based Local Conditions 38

Pb High Volume (TSP) 43

Pb Low Volume (PM

10

) 46

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 2 of 54

In June 1998, a workgroup was formed to develop a procedure that could be used by monitoring

organizations that would provide for a consistent validation of PM

2.5

mass concentrations across the US.

The workgroup included personnel from the monitoring organizations, EPA Regional Offices, and

OAQPS who were involved with assuring the quality of PM

2.5

mass; additionally, the workgroup was

headed by a State and local representative. The workgroup developed a table consisting of three criteria:

critical, operational, and systematic criteria, where each criterion had a different degree of implication

about the quality of the data. The criteria included on the tables were from 40 CFR Part 50 Appendices L

and N, 40 CFR Part 58 Appendix A, and Method 2.12; a few criteria were also added that were neither in

CFR nor Method 2.12, but which the workgroup felt should be included. Upon completion and use of the

table, it was decided that a “validation template” should be developed for all the criteria pollutants.

To determine the appropriate table for each criterion, the members of the workgroup considered how

significantly the criterion impacted the resulting concentration. This was based on experience from

workgroup members, experience from non-workgroup members, and feasibility of implementing the

criterion.

Criteria that were deemed critical to maintaining the integrity of a sample or group of samples were

placed on the first table. Observations that do not meet each and every criterion on the Critical Criteria

should be invalidated unless there are compelling reason and justification for not doing so. In most cases,

this criterion can identify a distinct group of measurements and time period. For example, a flow rate

exceedance represents a single sampler for a particular period of time (and therefore distinct number of

samples), whereas a field blank or QA collocation exceedance is harder to identify what samples the

exceedance may represent. In most cases the requirement, the implementation frequency of the criteria,

and the acceptance criteria are found in CFR and are therefore regulatory in nature. The sample or group

of samples for which one or more of these criteria are not met is invalid until proven otherwise

0F

1

. The

cause of not operating in the acceptable range for each of the violated criteria must be investigated and

minimized to reduce the likelihood that additional samples will be invalidated. Typically, EPA Regional

Offices will be in the best position to assess whether there are compelling reasons and justification for not

deleting the data. The evaluation will be informed by a weight of evidence approach, consider input from

States/locals and EPA’s national office, and be documented.

Criteria that are important for maintaining and evaluating the quality of the data collection system are

included under Operational Criteria. Violation of a criterion or a number of criteria may be cause for

invalidation. The decision maker should consider other quality control information that may or may not

indicate the data are acceptable for the parameter being controlled. Therefore, the sample or group of

samples for which one or more of these criteria are not met are suspect unless other quality control

information demonstrates otherwise and is documented. The reason for not meeting the criteria MUST be

investigated, mitigated or justified.

Finally, those criteria which are important for the correct interpretation of the data but do not usually

impact the validity of a sample or group of samples are included on the third table, the Systematic

Criteria. For example, the data quality objectives are included in this table. If the data quality objectives

are not met, this does not invalidate any of the samples but it may impact the uncertainty associated with

the attainment/non-attainment decision.

1

In a number of cases precedence has been set with invalidating data based on failure of critical criteria.

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 3 of 54

NOTE: The designation of quality control checks as Operational or Systematic do not

imply that these quality control checks need not be performed. Not performing an

operational or systematic quality control check that is required by regulation (in CFR) can be a

basis for invalidation of all associated data. Any time a CFR requirement is identified in the

Requirement, Frequency or Acceptance Criteria column it will be identified by bold and italics

font. Many monitoring organization/PQAOs are using the validation templates and have

included them in QAPPs. However, it must be mentioned that diligence must be paid to its

use. Data quality findings through data reviews and technical systems audits have identified

multiple and concurrent non-compliance with operational criteria that monitoring organization

considered valid without any documentation to prove the data validity. The validation

templates were meant to be applied to small data sets (single values or a few weeks of

information) and should not be construed to allow a criterion to be in non-conformance simple

because it is operational or systematic

Following are the tables for all the criteria pollutants. For each criterion, the tables include: (1) the

requirement (2) the frequency with which compliance is to be evaluated, (3) acceptance criteria, and (4)

information where the requirement can be found or additional guidance on the requirement.

The validation templates have been developed based on the current state of knowledge. The templates

should evolve as new information is discovered about the impact of the various criteria on the uncertainty

in the resulting mass estimate or concentration. In recent years there has been a number of circumstances

where critical criteria and in some cases operational criteria that were in regulation (had a frequency and

acceptance criteria) where not met. In these cases, EPA has been consistent in their application of

invalidating data not meeting regulations. Interactions of the criteria, whether synergistic or antagonistic,

should also be incorporated when the impact of these interactions becomes quantified. Due to the

potential misuse of invalid data, data that are invalidated should not be uploaded to AQS, but should be

retained on the monitoring organization’s local database. This data will be invaluable to the evolution of

the validation template.

Use of Bold Italics Font to Identify CFR Requirements.

The criteria listed in the validation templates are either requirements that can be found in the Code of

Federal Regulations, guidance found in a variety of guidance documents, or recommendations by the QA

Workgroup or EPA. As mentioned above any time a CFR requirement is identified in the Requirement,

Frequency or Acceptance Criteria column it will be identified by bold and italics font and can be used for

data invalidation depending on the infraction. The Information/Action column will provide the

appropriate references for CFR or guidance documents.

Hyperlink References

Where requirements or guidance documents are found on the web, a hyperlink is created which will lead

the user to the closest URL address. Any links to CFR are directed to the electronic CFR document (e-

CFR) which is the most up-to-date. E-CFR will not get you to an individual section. Therefore, e-CFR is

only hyperlinked once on each page.

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 4 of 54

Change in Acceptance Criteria

In order to provide more consistent guidance in the use of acceptance criteria we have developed more

definitive information on rounding. The acceptance criteria will show more digits than might otherwise

be found in regulations or guidance. For example, where in the past the one-point flow rate verification

was + 4% of transfer standard, some monitoring organizations equated a flow rate of < + 4.5% as

acceptable while others considered anything < + 4.1% acceptable. Therefore, in order to ensure

consistency, EPA has provided more definitive information of these acceptance limits. In this case, the

acceptance criteria for the flow rate verification is < + 4.1%. In the cases where the CFR lists a

requirement (as is the case with the flow rate verification which is listed as + 4%), EPA will interpret the

acceptance criteria to a level that will provide a more consistent application of the template across the

ambient air monitoring network. The rounding policy is included in Appendix L of the QA Handbook.

Truncation

Under no circumstances should quality measurements for comparison to acceptance criteria be truncated,

rather than rounded.

PM

10

Note of Caution

The validation templates for PM

10

get complicated because PM

10

is required to be reported at standard

temperature and pressure (STP) for comparison to the NAAQS (and follow 40 CFR Part 50 App J) and at

local conditions if using it to monitor for PM

10-2.5

(and follow 40 CFR Part 50 App O). Moreover, PM

10

can be measured with filter-based sampling techniques as well as with automated methods. The

validation templates developed for PM

10

try to accommodate these differences, but monitoring

organizations are cautioned to review the operations manual for the monitors/samplers they use and

augment the validation template with QC information specific to their EPA reference or equivalent

method designation and instrument.

http://www.epa.gov/ttn/amtic/files/ambient/criteria/reference-

equivalent-methods-list.pdf

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 5 of 54

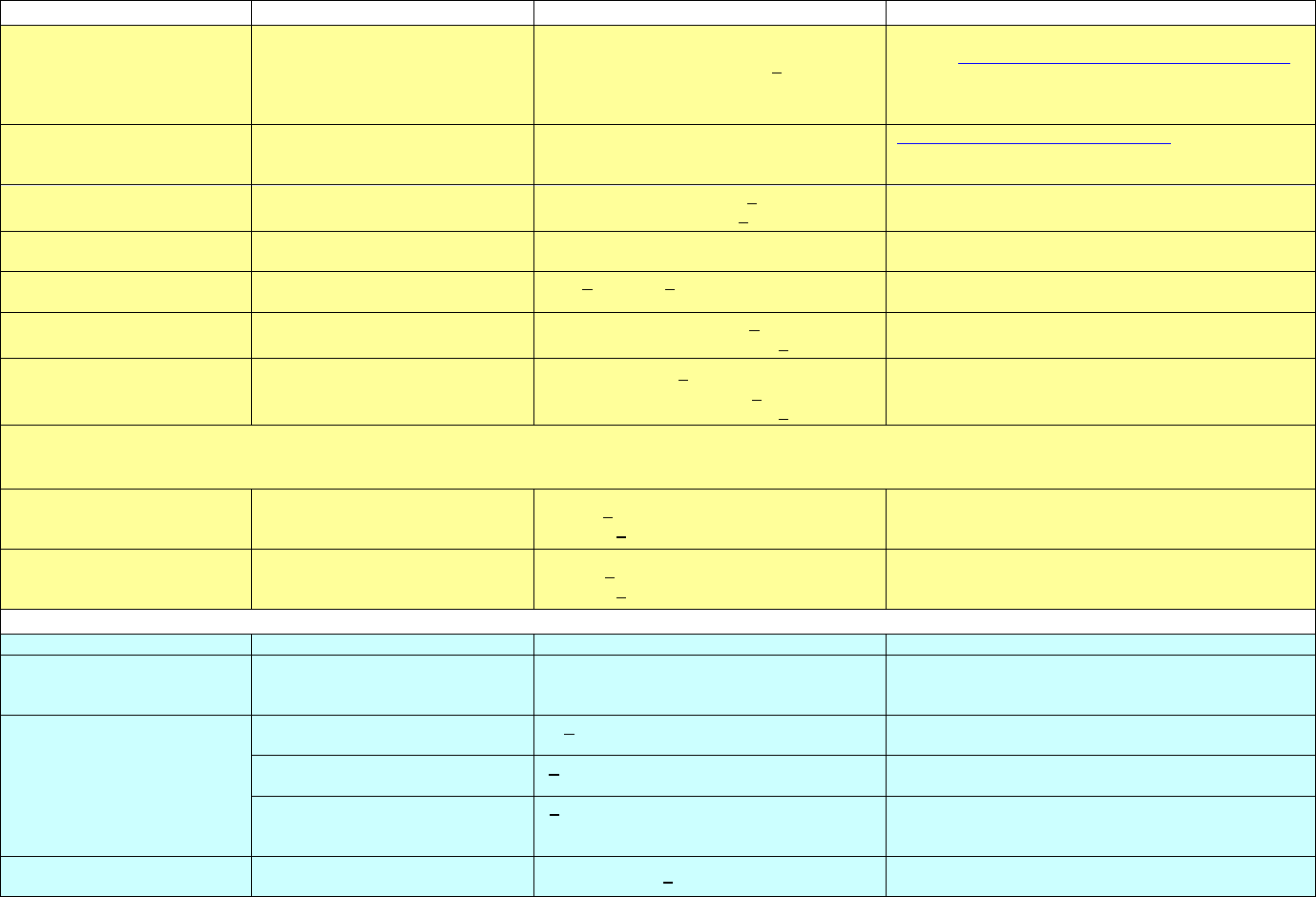

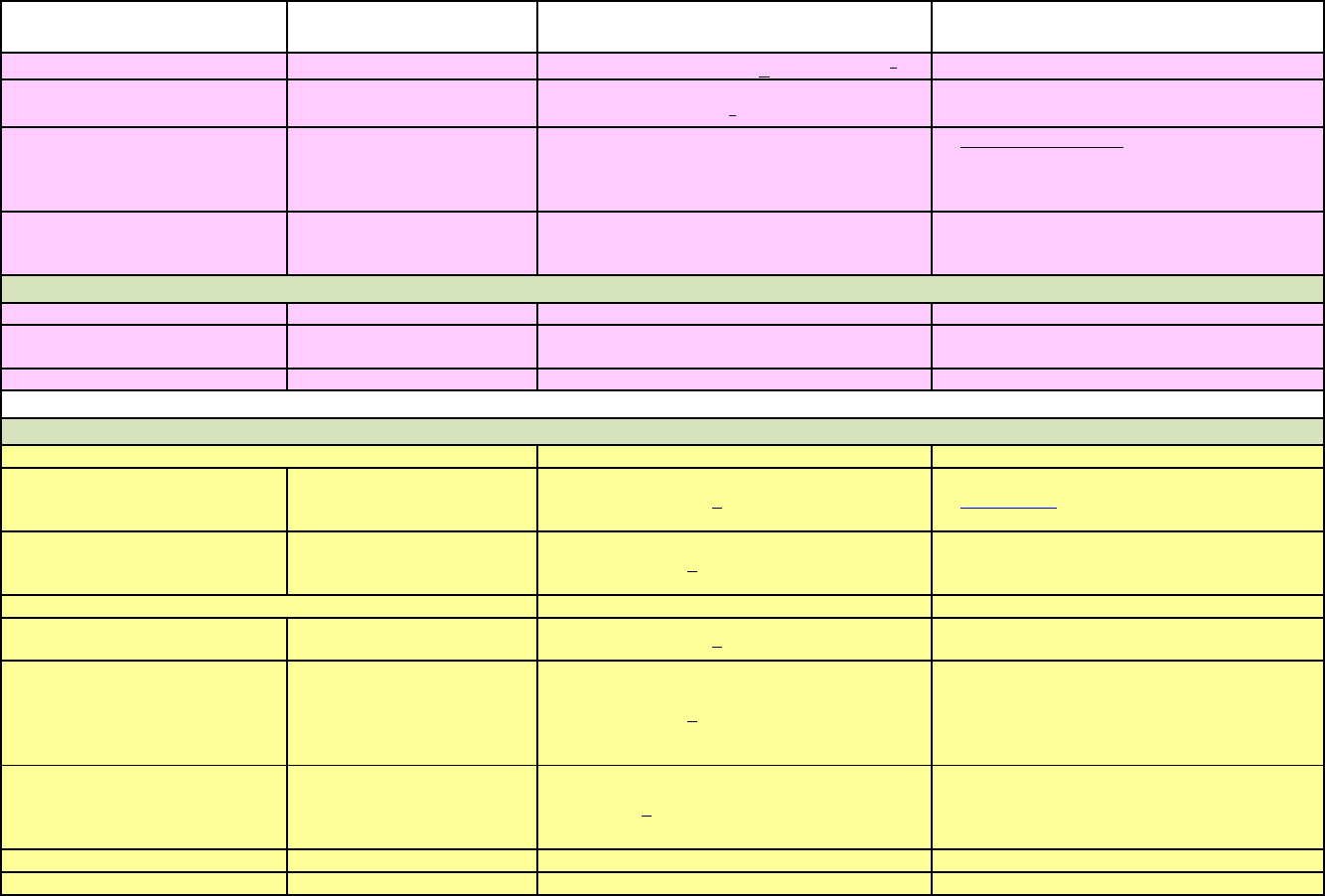

Ozone Validation Template

1) Requirement (O

3

) 2) Frequency 3) Acceptance Criteria Information /Action

CRITICAL CRITERIA-OZONE

Monitor

NA

Meets requirements listed in FRM/FEM

designation

1) 40 CFR Part 58 App C Sec. 2.1

2) NA

3) 40 CFR Part 53 & FRM/FEM method list

One Point QC Check

Single analyzer

Every 14 days

< +7.1% (percent difference) or < +1.5 ppb

difference whichever is greater

1 and 2) 40 CFR Part 58 App A Sec. 3.1

3) Recommendation based on DQO in 40 CFR Part 58

App A Sec. 2.3.1.2. QC Check Conc range 0.005 - 0.08

ppm and 05/05/2016 Technical Note on AMTIC

Zero/span check

Every 14 days

Zero drift < + 3.1 ppb (24 hr)

< + 5.1 ppb (>24hr-14 day)

Span drift < + 7.1 %

1 and 2) QA Handbook Volume 2 Sec. 12.3

3) Recommendation and related to DQO

OPERATIONAL CRITERIA -OZONE

Shelter Temperature Range

Daily

(hourly values)

20.0 to 30.0

o

C. (Hourly avg)

or

per manufacturers specifications if designated

to a wider temperature range

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Generally, the 20-30.0

o

C range will apply but the most

restrictive operable range of the instruments in the shelter

may also be used as guidance. FRM/FEM list found on

AMTIC provides temp. range for given instrument.

FRM/FEM monitor testing is required at 20-30

o

C range

per 40 CFR Part 53.32

Shelter Temperature Control Daily (hourly values) < 2.1

o

C SD over 24 hours 1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Shelter Temperature Device

Check

Every 182 days and 2/ calendar year

<+ 2.1

o

C of standard

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Annual Performance

Evaluation Single analyzer

Every site every 365 days and 1/

calendar year within period of

monitor operation,

Percent difference of audit levels 3-10

< +15.1%

Audit levels 1&2 < + 1.5 ppb difference or

<+ 15.1%

1 and 2) 40 CFR Part 58 App A Sec. 3.1.2

3) Recommendation- 3 audit concentrations not including

zero. AMTIC guidance 2/17/2011

AMTIC Technical Memo

Federal Audits (NPAP)

20% of sites audited in calendar

year

Audit levels 1&2 < + 1.5 ppb difference all

other levels percent difference < + 10.1%

1 and 2) 40 CFR Part 58 App A Sec. 3.1.3

3) NPAP QAPP/SOP

Verification/Calibration

Upon receipt/adjustment/repair/

installation/moving and repair and

recalibration of standard of higher

level

Every 182 day and 2/ calendar year if

manual zero/span performed

biweekly

Every 365 day and 1/ calendar year if

continuous zero/span performed daily

All points < + 2.1 % or < +1.5 ppb difference

of best-fit straight line whichever is greater

and Slope 1 + .05

1) 40 CFR Part 50 App D

2) Recommendation

3) 40 CFR Part 50 App D Sec 4.5.5.6

Multi-point calibration (0 and 4 upscale points)

Slope criteria is a recommendation

Zero Air/Zero Air Check

Every 365 days and 1/calendar year

Concentrations below LDL

1) 40 CFR Part 50 App D Sec. 4.1

2 and 3) Recommendation

Ozone Level 2 Standard

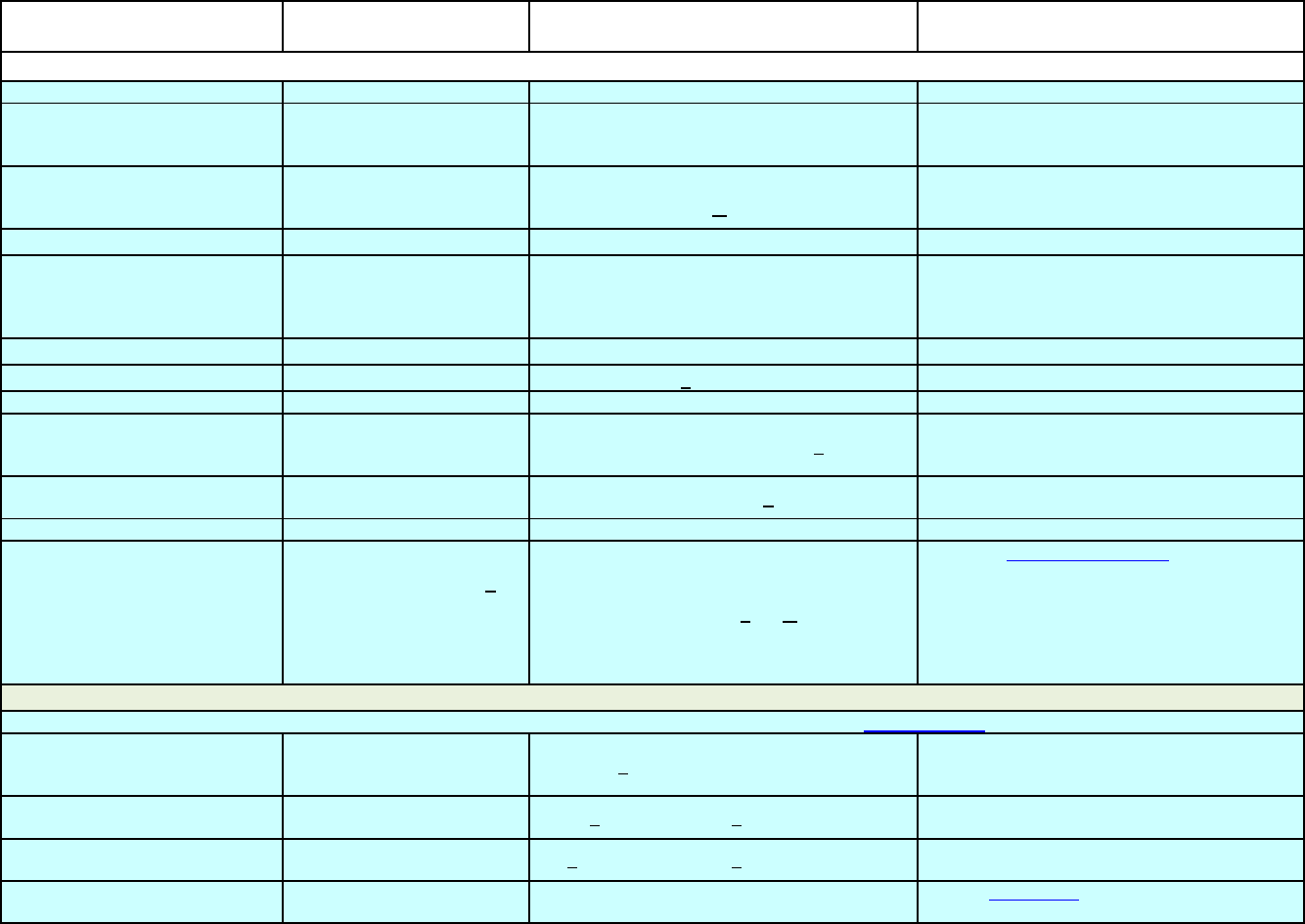

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 6 of 54

1) Requirement (O

3

) 2) Frequency 3) Acceptance Criteria Information /Action

Certification/recertification to

Standard Reference

Photometer (Level 1)

Every 365 days and 1/calendar year

single point difference < + 3.1%

1) 40 CFR Part 50 App D Sec. 5.4

2 and 3) Transfer Standard Guidance EPA-454/B-10-001

Level 2 standard (formerly called primary standard)

usually transported to EPA Regions SRP for comparison

Level 2 and Greater Transfer

Standard Precision

Every 365 days and 1/calendar year

Standard Deviation less than 0.005 ppm or

3.0% whichever is greater

1) 40 CFR Part 50 Appendix D Sec. 3.1

2) Recommendation, part of reverification

3) 40 CFR Part 50 Appendix D Sec. 3.1

(if recertified via a transfer

standard)

Every 365 days and 1/calendar year

Regression slopes = 1.00 + 0.03 and two

intercepts are 0 + 3 ppb

1, 2 and 3) Transfer Standard Guidance EPA-545/B-10-

001

Ozone Transfer standard

(Level 3 and greater)

Qualification Upon receipt of transfer standard

< +4.1% or < +4 ppb (whichever greater)

1, 2 and 3) Transfer Standard Guidance EPA-545/B-10-

001

Certification

After qualification and upon

receipt/adjustment/repair

RSD of six slopes < 3.7%

Std. Dev. of 6 intercepts < 1.5

1, 2 and 3) Transfer Standard Guidance EPA-545/B-10-

001 1

Recertification to higher level

standard

Beginning and end of O3 season or

every 182 days and 2/calendar year

whichever less

New slope = + 0.05 of previous and

RSD of six slopes <3.7%

Std. Dev. of 6 intercepts < 1.5

1, 2 and 3) Transfer Standard Guidance EPA-545/B-10-

001 recertification test that then gets added to most recent

5 tests. If does not meet acceptability certification fails

Detection (FEM/FRMs) Noise and Lower Detectable Limits (LDL) are part of the FEM/FRM requirements. It is recommended that monitoring organizations perform the LDL test to

minimally confirm and establish the LDL of their monitor. Performing the LDL test will provide the noise information.

Noise

Every 365 days and 1/ calendar year

< 0.0025 ppm (standard range)

< 0.001 ppm (lower range)

1) 40 CFR Part 53.23 (b) (definition & procedure)

2) Recommendation- info can be obtained from LDL

3) 40 CFR Part 53.20 Table B-1

Lower detectable limit

Every 365 days and 1/calendar year

< 0.005 ppm (standard range)

< 0.002 ppm (lower range)

1) 40 CFR Part 53.23 (b) (definition & procedure)

2) Recommendation

3) 40 CFR Part 53.20 Table B-1

SYSTEMATIC CRITERIA-OZONE

Standard Reporting Units All data ppm (final units in AQS)

1, 2 and 3) 40 CFR Part 50 App U Sec. 3(a)

Rounding convention for design

value calculation

All routine concentration data

3 places after decimal with digits to right

truncated

1, 2 and 3) 40 CFR Part 50 App U Sec. 3(a) The rounding

convention is for averaging values for comparison to

NAAQS not for reporting individual hourly values.

Completeness (seasonal)

3-Year Comparison

> 90% (avg) daily max available in ozone

season with min of 75% in any one year.

1,2,3) 40 CFR Part 50 App U Sec 4(b)

8- hour average

> if at least 6 of the hourly concentrations for

the 8-hour period are available

1) 40 CFR Part 50 App U

2 and 3) 40 CFR Part 50 App U Sec. 3(b)

Valid Daily Max

> if valid 8-hour averages are available for at

least 13 of the 17 consecutive 8-hour periods

starting from 7:00 a.m. to 11:00 p.m

1) 40 CFR Part 50 App U

2,3) 40 CFR Part 50 App U Sec. 3(d)

Sample Residence Time

Verification

Every 365 days and 1/calendar year

< 20 Seconds

1) 40 CFR Part 58 App E, Sec. 9 (c)

2) Recommendation

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 7 of 54

1) Requirement (O

3

) 2) Frequency 3) Acceptance Criteria Information /Action

3) 40 CFR Part 58 App E, Sec. 9 (c)

Sample Probe, Inlet, Sampling

train

All sites

Borosilicate glass (e.g., Pyrex

®

) or Teflon

®

1) 40 CFR Part 58 App E, Sec. Sec. 9 (a)

2) Recommendation

3) 40 CFR Part 58 App E, Sec. Sec. 9 (a)

FEP and PFA have been accepted as an equivalent

material to Teflon. Replacement or cleaning is suggested

as 1/year and more frequent if pollutant load or

contamination dictate

Siting

Every 365 days and 1/calendar year

Meets siting criteria or waiver documented

1) 40 CFR Part 58 App E, Sec. 2-6

2) Recommendation

3) 40 CFR Part 58 App E, Sec. 2-6

EPA Standard Ozone Reference

Photometer (SRP)

Recertification (Level 1)

Every 365 days and 1/calendar year

Regression slope = 1.00 + 0.01

and intercept < 3 ppb

1, 2 and 3) Transfer Standard Guidance EPA-454/B-10-

001

This is usually at a Regional Office and is compared

against the traveling SRP

Precision (using 1-point QC

checks)

Calculated annually and as

appropriate for design value

estimates

90% CL CV < 7.1%

1) 40 CFR Part 58 App A 2.3.1.2 & 3.1.1

2) 40 CFR Part 58 App A Sec. 4 (b)

3) 40 CFR Part 58 App A Sec. 4.1.2

Bias (using 1-point QC checks)

Calculated annually and as

appropriate for design value

estimates

95% CL < + 7.1%

1) 40 CFR Part 58 App A 2.3.1.2 & 3.1.1

2) 40 CFR Part 58 App A Sec. 4 (b)

3) 40 CFR Part 58 App A Sec. 4.1.3

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 8 of 54

CO Validation Template

1) Requirement (CO) 2) Frequency 3) Acceptance Criteria Information /Action

CRITICAL CRITERIA-CO

Sampler/Monitor

NA

Meets requirements listed in FRM/FEM

designation

1) 40 CFR Part 58 App C Sec. 2.1

2) NA

3) 40 CFR Part 53 & FRM/FEM method list

One Point QC Check

Single analyzer

Every 14 days

< +10.1% (percent difference)

1 and 2) 40 CFR Part 58 App A Sec. 3.1.1

3) Recommendation based on DQO in 40 CFR Part 58

App A Sec. 2.3.1. QC Check Conc range 0.5 – 5 ppm

Zero/span check

Every 14 days

Zero drift < + 0.41 ppm (24 hr)

< + 0.61 ppm (>24hr-14 day)

Span drift < + 10.1 %

1 and 2) QA Handbook Volume 2 Sec. 12.3

3) Recommendation

OPERATIONAL CRITERIA-CO

Shelter Temperature range

Daily

(hourly values)

20.0 to 30.0

o

C. (Hourly avg)

or

per manufacturers specifications if designated to a

wider temperature range

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Generally, the 20-30.0

o

C range will apply but the most

restrictive operable range of the instruments in the

shelter may also be used as guidance. FRM/FEM list

found on AMTIC provides temp. range for given

instrument. FRM/FEM monitor testing is required at

20-30

o

C range per 40 CFR Part 53.32

Shelter Temperature Control Daily (hourly values) < 2.1

o

C SD over 24 hours

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Shelter Temperature Device

Check

Every 182 days and 2/ calendar year < + 2.1

o

C of standard

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Annual Performance

Evaluation Single Analyzer

Every site every 365 days and 1/

calendar year

Percent difference of audit levels 3-10 < +15.1%

Audit levels 1&2 < + 0.031 ppm difference or

< +15.1%

1 and 2) 40 CFR Part 58 App A Sec. 3.1.2

3) Recommendation- 3 audit concentrations not

including zero. AMTIC Technical Memo

Federal Audits (NPAP)

20% of sites audited in a calendar

year

Audit levels 1&2 < + 0.031 ppm difference all

other levels percent difference < + 15.1%

1 and 2) 40 CFR Part 58 App A Sec. 3.1.3

3) NPAP QAPP/SOP

Verification/Calibration

Upon receipt/adjustment/repair/

installation/moving

Every 182 day and 2/ calendar year if

manual zero/span performed

biweekly

Every 365 days and 1/ calendar year

if continuous zero/span performed

daily

All points < + 2.1 % or < + 0.03 ppm difference

of best-fit straight line. whichever is greater

and Slope 1 + .05

1) 40 CFR Part 50 Appendix C Sec. 4

2 and 3) Recommendation

See details about CO2 sensitive instruments Multi-point

calibration (0 and 4 upscale points)

Slope criteria is a recommendation

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 9 of 54

1) Requirement (CO) 2) Frequency 3) Acceptance Criteria Information /Action

Gaseous Standards

All gas cylinders

NIST Traceable

(e.g., EPA Protocol Gas)

1) 40 CFR Part 50 Appendix C Sec. 4.3.1

2) NA Green Book

3) 40 CFR Part 50 Appendix C Sec. 4.3.1 See details

about CO2 sensitive instruments

Gas producer used must participate in EPA Ambient Air

Protocol Gas Verification Program

40 CFR Part 58 App A Sec. 2.6.1

Zero Air/Zero Air Check

Every 365 days and 1/ calendar year

< 0.1 ppm CO

1) 40 CFR Part 50 App C Sec. 4.3.2

2) Recommendation

3) 40 CFR Part 50 App C Sec. 4.3.2

Gas Dilution Systems

Every 365 days and 1/ calendar year

or after failure of 1 point QC check or

performance evaluation

Accuracy < + 2.1 %

1, 2 and 3) Recommendation based on SO2

requirement in 40 CFR Part 50 App A-1 Sec. 4.1.2

Detection (FEM/FRMs) Noise and Lower Detectable Limits (LDL) are part of the FEM/FRM requirements. It is recommended that monitoring organizations perform the LDL test to

minimally confirm and establish the LDL of their monitor. Performing the LDL test will provide the noise information.

Noise

Every 365 days and 1/ calendar year

< 0.2 ppm (standard range)

< 0.1 ppm (lower range)

1) 40 CFR Part 53.23 (b) (definition & procedure)

2) Recommendation- info can be obtained from LDL

3) 40 CFR Part 53.20 Table B-1

Lower detectable level

Every 365 days and 1/ calendar year

< 0.4 ppm (standard range)

< 0.2 ppm (lower range)

1) 40 CFR Part 53.23 (c) (definition & procedure)

2) Recommendation

3) 40 CFR Part 53.20 Table B-1

SYSTEMATIC CRITERIA-CO

Standard Reporting Units All data ppm (final units in AQS)

1, 2 and 3) 40 CFR Part 50.8 (a)

Rounding convention for design

value calculation

All routine concentration data 1 decimal place

1, 2 and 3) 40 CFR Part 50.8 (d) The rounding

convention is for averaging values for comparison to

NAAQS not for reporting individual hourly values.

Completeness 8-hour standard 75% of hourly averages for the 8-hour period

1) 40 CFR Part 50.8(c)

2) 40 CFR Part 50.8(a-2)

3) 40 CFR Part 50.8(c)

Sample Residence Time

Verification

Every 365 days and 1/ calendar year < 20 Seconds

1, 2, and 3) Recommendation. CO not a reactive gas but

suggest following same methods other gaseous criteria

pollutants.

Sample Probe, Inlet, Sampling

train

All Sites

Borosilicate glass (e.g., Pyrex

®

) or Teflon

®

1, 2, and 3) Recommendation. CO not a reactive gas

but suggest following same methods other gaseous

criteria pollutants. FEP and PFA have been accepted as

a equivalent material to Teflon. Replacement/cleaning is

suggested as 1/year and more frequent if pollutant load

dictate.

Siting

Every 365 days and 1/ calendar year

Meets siting criteria or waiver documented

1) 40 CFR Part 58 App E, Sec. 2-6

2) Recommendation

3) 40 CFR Part 58 App E, Sec. 2-6

Precision (using 1-point QC Calculated annually and as 90% CL CV < 10.1%

1) 40 CFR part 58 App A Sec. 3.1.1

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 10 of 54

1) Requirement (CO) 2) Frequency 3) Acceptance Criteria Information /Action

checks) appropriate for design value

estimates

2) 40 CFR Part 58 App A Sec. 4 (b)

3) 40 CFR Part 58 App A Sec. 4.1.2

Bias (using 1-point QC checks)

Calculated annually and as

appropriate for design value

estimates

95% CL < + 10.1%

1) 40 CFR Part 58 App A Sec. 3.1.1

2) 40 CFR Part 58 App A Sec. 4 (b)

3) 40 CFR Part 58 App A Sec. 4.1.3

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 11 of 54

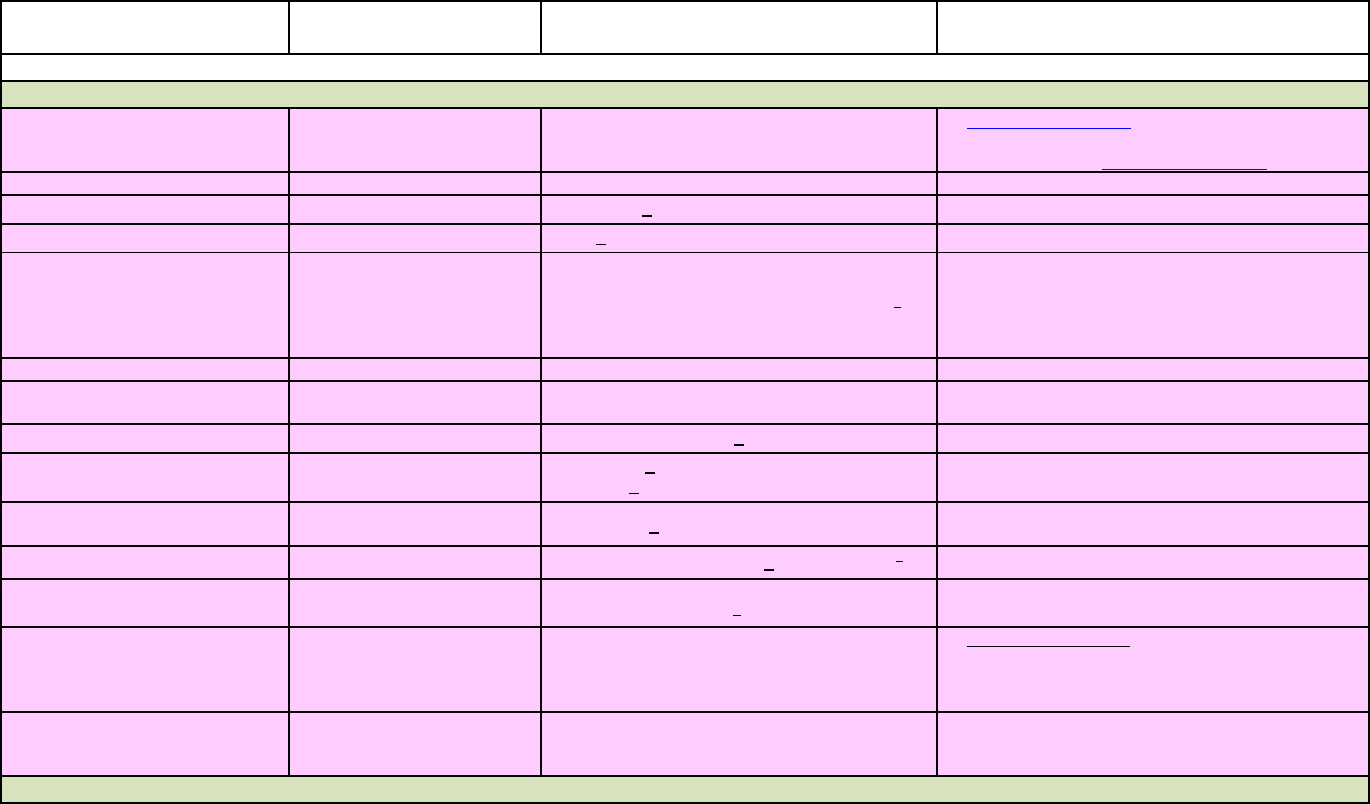

NO

2

, NOx, NO Validation Template

1) Requirement (NO

2

) 2) Frequency 3) Acceptance Criteria Information /Action

CRITICAL CRITERIA- NO

2

Sampler/Monitor NA

Meets requirements listed in FRM/FEM

designation

1) 40 CFR Part 58 App C Sec. 2.1

2) NA

3) 40 CFR Part 53 & FRM/FEM method list

One Point QC Check

Single analyzer

Every 14 days

< +15.1% (percent difference) or < + 1.5 ppb

difference whichever is greater

1 and 2) 40 CFR Part 58 App A Sec. 3.1.1

3) Recommendation based on DQO in 40 CFR Part 58

App A Sec. 2.3.1.5 QC Check Conc range 0.005 - 0.08

ppm and 05/05/2016 Technical Note on AMTIC

Zero/span check

Every 14 days

Zero drift < + 3.1 ppb (24 hr)

< + 5.1 ppb (>24hr-14 day)

Span drift < + 10.1 %

1 and 2) QA Handbook Volume 2 Sec. 12.3

3) Recommendation and related to DQO

Converter Efficiency

During multi-point calibrations, span and

audit

Every 14 days

(>96%)

96% – 104.1%

1) 40 CFR Part 50 App F Sec. 1.5.10 and 2.4.10

2) Recommendation

3) 40 CFR Part 50 App F Sec. 1.5.10 and 2.4.10

Regulation states > 96%, 96 – 104.1% is a

recommendation.

OPERATIONAL CRITERIA- NO

2

Shelter Temperature Range

Daily

(hourly values)

20.0 to 30.0

o

C. (Hourly avg)

or

per manufacturers specifications if designated

to a wider temperature range

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Generally, the 20-30.0

o

C range will apply but the

most restrictive operable range of the instruments in

the shelter may also be used as guidance. FRM/FEM

list found on AMTIC provides temp. range for given

instrument. FRM/FEM monitor testing is required at

20-30

o

C range per 40 CFR Part 53.32

Shelter Temperature Control Daily (hourly values) < 2.1

o

C SD over 24 hours

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Shelter Temperature Device

Check

every 182 days and 2/calendar year < + 2.1

o

C of standard

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Annual Performance

Evaluation Single Analyzer

Every site every 365 days and 1/

calendar year

Percent difference of audit levels 3-10

< +15.1%

Audit levels 1&2 < + 1.5 ppb difference or

< +15.1%

1) 40 CFR Part 58 App A Sec. 3.1.2

2) 40 CFR Part 58 App A Sec. 3.1.2

3) Recommendation - 3 audit concentrations not

including zero. AMTIC Technical Memo

Federal Audits (NPAP)

20% of sites audited in calendar year

Audit levels 1&2 < + 1.5 ppb difference all

other levels percent difference < + 15.1%

1 & 2) 40 CFR Part 58 App A Sec. 3.1.3

3) NPAP QAPP/SOP

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 12 of 54

1) Requirement (NO

2

) 2) Frequency 3) Acceptance Criteria Information /Action

Verification/Calibration

Upon receipt/adjustment/repair/

installation/moving

Every 182 day and 2/ calendar year if

manual zero/span performed biweekly

Every 365 day and 1/ calendar year if

continuous zero/span performed daily

Instrument residence time < 2 min

Dynamic parameter > 2.75 ppm-min

All points <+ 2.1 % or < + 1.5 ppb difference

of best-fit straight line whichever is greater

and Slope 1 + .05

1) 40 CFR Part 50 App F

2 and 3) Recommendation

Multi-point calibration (0 and 4 upscale points)

Slope criteria is a recommendation

Gaseous Standards

All gas cylinders

NIST Traceable

(e.g., EPA Protocol Gas)

50-100 ppm of NO in Nitrogen with < 1 ppm

NO

2

1) 40 CFR Part 50 App F Sec. 1.3.1

2) NA Green Book

3) 40 CFR Part 50 App F Sec. 1.3.1. A technical

memo may change the concentration requirment.

Gas producer used must participate in EPAAmbient

Air Protocol Gas Verification Program 40 CFR Part

58 App A Sec. 2.6.1

Zero Air/ Zero Air Check

Every 365 days and 1/ calendar year Concentrations below LDL

1) 40 CFR Part 50 App F Sec. 1.3.2

2 and 3) Recommendation

Gas Dilution Systems

Every 365 days and 1/ calendar year or

after failure of 1 point QC check or

performance evaluation

Accuracy < + 2.1 %

1, 2 and 3) Recommendation based on SO2

requirement in 40 CFR Part 50 App A-1 Sec. 4.1.2

Detection (FEM/FRMs) Noise and Lower Detectable Limits (LDL) are part of the FEM/FRM requirements. It is recommended that monitoring organizations perform the LDL test to

minimally confirm and establish the LDL of their monitor. Performing the LDL test will provide the noise information.

Noise

Every 365 days and 1/ calendar year

< 0.005 ppm

1) 40 CFR Part 53.23 (b) (definition & procedure)

2) Recommendation- info can be obtained from LDL

3) 40 CFR Part 53.20 Table B-1

Lower detectable level

Every 365 days and 1/ calendar year

< 0.01 ppm

1) 40 CFR Part 53.23 (c) (definition & procedure)

2) Recommendation

3) 40 CFR Part 53.20 Table B-1

SYSTEMATIC CRITERIA- NO

2

Standard Reporting Units All data ppb (final units in AQS)

1, 2 and 3) 40 CFR Part 50 App S Sec. 2 (c)

Rounding convention for data

reported to AQ S

All routine concentration data

1 place after decimal with digits to right

truncated

1, 2 and 3) 40 CFR Part 50 App S Sec. 4.2 (a) The

rounding convention is for averaging values for

comparison to NAAQS not for reporting individual

hourly values.

Completeness

Annual Standard

≥ 75% hours in year

1) 40 CFR Part 50 App S Sec. 3.1(b)

2) 40 CFR Part 50 App S Sec. 3.1(a)

3) 40 CFR Part 50 App S Sec. 3.1(b)

1-hour standard

1) 3consecutive calendars years of complete

data

2) 4 quarters complete in each year

3) ≥75% sampling days in quarter

4) ≥ 75% of hours in a day

1) 40 CFR Part 50 App S Sec. 3.2(b)

2) 40 CFR Part 50 App S Sec. 3.2(a)

3) 40 CFR Part 50 App S Sec. 3.2(b)

More details in 40 CFR Part 50 App S

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 13 of 54

1) Requirement (NO

2

) 2) Frequency 3) Acceptance Criteria Information /Action

Sample Residence Time

Verification

Every 365 days and 1/ calendar year

< 20 Seconds

1) 40 CFR Part 58 App E, Sec. 9 (c)

2) Recommendation

3) 40 CFR Part 58 App E, Sec. 9 (c)

Sample Probe, Inlet, Sampling

train

All sites

Borosilicate glass (e.g., Pyrex

®

) or Teflon

®

1, 2 and 3) 40 CFR Part 58 App E Sec. 9 (a)

FEP and PFA have been accepted as equivalent

material to Teflon. Replacement or cleaning is

suggested as 1/year and more frequent if pollutant load

or contamination dictate

Siting

Every 365 days and 1/ calendar year

Meets siting criteria or waiver documented

1) 40 CFR Part 58 App E, Secs 2-6

2) Recommendation

3) 40 CFR Part 58 App E, Sec. 2-6

Precision (using 1-point QC

checks)

Calculated annually and as appropriate

for design value estimates

90% CL CV < 15.1%

1) 40 CFR Part 58 App A Sec. 2.3.1.5 & 3.1.1

2) 40 CFR Part 58 App A Sec. 4 (b)

3) 40 CFR Part 58 App A Sec. 4.1.2

Bias (using 1-point QC checks)

Calculated annually and as appropriate

for design value estimates

95% CL < + 15.1%

1) 40 CFR Part 58 App A Sec. 2.3.1.5 & 3.1.1

2) 40 CFR Part 58 App A Sec. 4 (b)

3) 40 CFR Part 58 App A Sec. 4.1.3

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 14 of 54

SO

2

Validation Template

1) Requirement (SO

2

) 2) Frequency 3) Acceptance Criteria Information /Action

CRITICAL CRITERIA- SO

2

Sampler/Monitor

NA

Meets requirements listed in FRM/FEM

designation

1) 40 CFR Part 58 App C Sec. 2.1 2) NA

3) 40 CFR Part 53 & FRM/FEM method list

One Point QC Check

Single analyzer

Every 14 days

< +10.1% (percent difference) or < + 1.5 ppb

difference whichever is greater

1 and 2) 40 CFR Part 58 App A Sec. 3.1.1

3) Recommendation based on DQO in 40 CFR Part 58

App A Sec. 2.3.1.2 QC Check Conc range 0.005 - 0.08

ppm and 05/05/2016 Technical Note on AMTIC

Zero/span check

Every 14 days

Zero drift < + 3.1 ppb (24 hr)

< + 5.1 ppb (>24hr-14 day)

Span drift < + 10.1 %

1 and 2) QA Handbook Volume 2 Sec. 12.3

3) Recommendation and related to DQO

OPERATIONAL CRITERIA- SO

2

Shelter Temperature Range

Daily

(hourly values)

20.0 to 30.0

o

C. (Hourly avg)

or

per manufacturers specifications if designated to

a wider temperature range

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Generally, the 20-30.0

o

C range will apply but the most

restrictive operable range of the instruments in the

shelter may also be used as guidance. FRM/FEM list

found on AMTIC provides temp. range for given

instrument. FRM/FEM monitor testing is required at 20-

30

o

C range per 40 CFR Part 53.32

Shelter Temperature Control Daily (hourly values) < 2.1

o

C SD over 24 hours

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Shelter Temperature Device

Check

every 180 days and 2/calendar year < + 2.1

o

C of standard

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Annual Performance

Evaluation Single Analyzer

Every site every 365 days and 1/

calendar year

Percent difference of audit levels 3-10

< +15.1%

Audit levels 1&2 < + 1.5 ppb difference or

< +15.1%

1 and 2) 40 CFR Part 58 App A Sec. 3.1.2

3) Recommendation - 3 audit concentrations not

including zero. AMTIC Technical Memo

Federal Audits (NPAP)

20% of sites audited in calendar year

Audit levels 1&2 < + 1.5 ppb difference all

other levels percent difference < + 15.1%

1&2) 40 CFR Part 58 App A Sec. 3.1.3

3) NPAP QAPP/SOP

Verification/Calibration

Upon receipt/adjustment/repair/

installation/moving

Every 182 day and 2/ calendar year if

manual zero/span performed biweekly

Every 365 day and 1/ calendar year if

continuous zero/span performed daily

All points < + 2.1 % or < + 1.5 ppb difference

of best-fit straight line whichever is greater

and Slope 1 + .05

1) 40 CFR Part 50 App A-1 Sec. 4

2 and 3) Recommendation

Multi-point calibration (0 and 4 upscale points)

Slope criteria is a recommendation

Gaseous Standards All gas cylinders

NIST Traceable

(e.g., EPA Protocol Gas)

1) 40 CFR Part 50 App A-1 Sec. 4.1.6.1

2) NA Green Book

3) 40 CFR Part 50 App F Sec. 1.3.1

Producers must participate in Ambient Air Protocol Gas

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 15 of 54

1) Requirement (SO

2

) 2) Frequency 3) Acceptance Criteria Information /Action

Verification Program 40 CFR Part 58 App A Sec. 2.6.1

Zero Air/ Zero Air Check

Every 365 days and 1/ calendar year

Concentrations below LDL

< 0.1 ppm aromatic hydrocarbons

1) 40 CFR Part 50 App A-1 Sec. 4.1.6.2

2) Recommendation

3) Recommendation and 40 CFR Part 50 App A-1 Sec.

4.1.6.2

Gas Dilution Systems

Every 365 days and 1/ calendar year or

after failure of 1point QC check or

performance evaluation

Accuracy < + 2.1 %

1) 40 CFR Part 50 App A-1Sec. 4.1.2

2) Recommendation

3) 40 CFR Part 50 App A-1 Sec. 4.1.2

Detection (FEM/FRMs) Noise and Lower Detectable Limits (LDL) are part of the FEM/FRM requirements. It is recommended that monitoring organizations perform the LDL test to

minimally confirm and establish the LDL of their monitor. Performing the LDL test will provide the noise information.

Noise

Every 365 days and 1/ calendar year

< 0.001 ppm (standard range)

< 0.0005 ppm (lower range)

1) 40 CFR Part 53.23 (b) (definition & procedure)

2) Recommendation- info can be obtained from LDL

3) 40 CFR Part 53.20 Table B-1

Lower detectable level

Every 365 days and 1/ calendar year

< 0.002 ppm (standard range)

< 0.001 ppm (lower range)

1) 40 CFR Part 53.23 (c) (definition & procedure)

2) Recommendation

3) 40 CFR Part 53.20 Table B-1

SYSTEMATIC CRITERIA- SO

2

Standard Reporting Units All data ppb (final units in AQS)

1, 2 and 3) 40 CFR Part 50 App T Sec. 2 (c)

Rounding convention for design

value calculation

All routine concentration data

1 place after decimal with digits to right

truncated

1, 2 and 3) 40 CFR Part 50 App T Sec. 2 (c) The

rounding convention is for averaging values for

comparison to NAAQS not for reporting individual

hourly values.

Completeness 1 hour standard

Hour – 75% of hour

Day- 75% hourly Conc

Quarter- 75% complete days

Years- 4 complete quarters

5-min value reported only for valid hours

1, 2 and 3) 40 CFR Part 50 App T Sec. 3 (b), (c)

More details in CFR on acceptable completeness.

5-min values or 5-min max value (40 CFR part 58.16(g))

only reported for the valid portion of the hour reported. If

the hour is incomplete no 5-min or 5-min max reported.

Sample Residence Time

Verification

Every 365 days and 1/ calendar year

< 20 Seconds

1) 40 CFR Part 58 App E, Sec. 9 (c)

2) Recommendation

3) 40 CFR Part 58 App E, Sec. 9 (c)

Sample Probe, Inlet, Sampling

train

All sites

Borosilicate glass (e.g., Pyrex

®

) or Teflon

®

1, 2 and 3) 40 CFR Part 58 App E Sec. 9 (a)

FEP and PFA have been accepted as equivalent material

to Teflon. Replacement or cleaning is suggested as

1/year and more frequent if pollutant load or

contamination dictate

Siting

Every 365 days and 1/ calendar year

Meets siting criteria or waiver documented

1) 40 CFR Part 58 App E, Sec. 2-6

2) Recommendation

3) 40 CFR Part 58 App E, Sec. 2-6

Precision (using 1-point QC

checks)

Calculated annually and as appropriate

for design value estimates

90% CL CV < 10.1%

1) 40 CFR Part 58 App A Sec. 2.3.1.6 & 3.1.1

2) 40 CFR Part 58 App A Sec. 4 (b)

3) 40 CFR Part 58 App A Sec. 4.1.2

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 16 of 54

1) Requirement (SO

2

) 2) Frequency 3) Acceptance Criteria Information /Action

Bias (using 1-point QC checks)

Calculated annually and as appropriate

for design value estimates

95% CL < + 10.1%

1) 40 CFR Part 58 App A Sec. 2.3.1.6 & 3.1.1

2) 40 CFR Part 58 App A Sec. 4 (b)

3) 40 CFR Part 58 App A Sec. 4.1.3

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 17 of 54

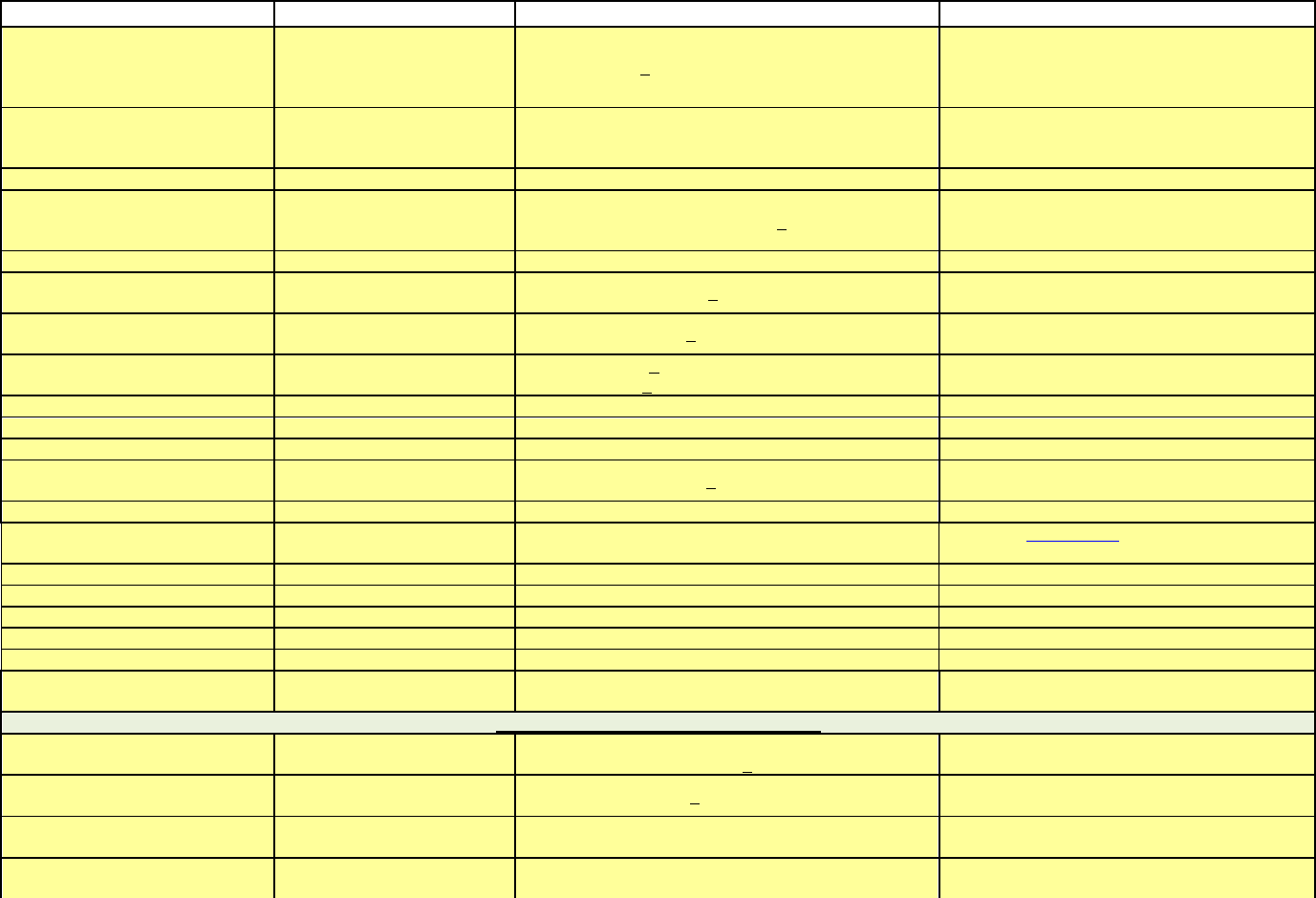

PM

2.5

Filter Based Local Conditions Validation Template

1) Criteria (PM2.5 LC) 2) Frequency 3) Acceptable Range Information /Action

CRITICAL CRITERIA- PM

2.5

Filter Based Local Conditions

Field Activities

Sampler/Monitor

NA

Meets requirements listed in FRM/FEM/ARM

designation

1) 40 CFR Part 58 App C Sec. 2.1

2) NA

3) 40 CFR Part 53 & FRM/FEM method list

Filter Holding Times

Pre-sampling all filters

< 30 days before sampling

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.3.5

Sample Recovery all filters

< 7 days 9 hours from sample end date

1, 2 and 3) 40 CFR Part 50, App. L 10.10

Sampling Period (including

multiple power failures)

all filters

1380-1500 minutes, or

if value < 1380 and exceedance of NAAQS

1/

midnight to midnight local standard time

1, 2 and 3) 40 CFR Part 50 App L Sec. 3.3 and 40 CFR

Part 50 App N Sec. 1 for the midnight to midnight local

standard time requirement

See details if less than 1380 min sampled

Sampling Instrument

Average Flow Rate every 24 hours of op average within 5% of 16.67 liters/minute

1, 2 and 3) Part 50 App L Sec. 7.4.3.1

Variability in Flow Rate every 24 hours of op

CV < 2%

1, 2 and 3) 40 CFR Part 50, App L Sec. 7.4.3.2

One-point Flow Rate Verification

every 30 days each seperated

by 14 days

< + 4.1% of transfer standard

< + 5.1% of flow rate design value

1, 2 and 3) 40 CFR Part 50, App L, Sec. 9.2.5 and

7.4.3.1 and 40 CFR Part 58, Appendix A Sec. 3.2.1

Design Flow Rate Adjustment

After multi-point calibration or

verification

< + 2.1% of design flow rate

1, 2 and 3) 40 CFR Part 50, App. L, Sec. 9.2.6

Individual Flow Rates every 24 hours of op

no flow rate excursions > +5% for > 5 min.

1

/

1, 2 and 3) 40 CFR Part 50, App. L Sec. 7.4.3.1

Filter Temp Sensor every 24 hours of op

no excursions of > 5

o

C lasting longer than 30 min

1/

1, 2 and 3) 40 CFR Part 50, App. L Sec. 7.4.11.4

External Leak Check

Before each flow rate

verification/calibration and

before and after PM

2.5

separator

maintenance

< 80.1 mL/min (see comment #1)

1) 40 CFR Part 50 App L, Sec. 7.4.6.1

2) 40 CFR Part 50 App L Sec. 9.2.3 and Method 2-12

Sec. 7.4.3

3) 40 CFR Part 50, App. L, Sec. 7.4.6.1

Internal Leak Check

If failure of external leak check

< 80.1 mL/min

1) 40 CFR Part 50, App. L, Sec. 7.4.6.2

2) Method 2-12, Sec. 7.4.4

3) 40 CFR Part 50, App. L, Sec. 7.4.6.2

Laboratory Activities

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 18 of 54

1) Criteria (PM2.5 LC) 2) Frequency 3) Acceptable Range Information /Action

Post-sampling Weighing all filters

Protected from exposure to temperatures above

25C from sample retrieval to conditioning

<10 days from sample end date if shipped at

ambient temp, or

< 30 days if shipped below avg ambient (or 4

o

C or

below for avg sampling temps < 4

o

C ) from

sample end date

1, 2 and 3) 40 CFR Part 50 App L Sec. 8.3.6 and

L Sec. 10.13.

See technical note on holding time requirements at :

https://www3.epa.gov/ttn/amtic/pmpolgud.html

Filter Visual Defect Check

(unexposed)

all filters

Correct type & size and for pinholes, particles or

imperfections

1, 2 and 3) 40 CFR Part 50, App. L Sec. 10.2

Filter Conditioning Environment

Equilibration all filters 24 hours minimum

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.2.5

Temp. Range all filters 24-hr mean 20.0-23.0

o

C

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.2.1

Temp. Control

all filters < 2.1

o

C SD* over 24 hr.

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.2.2 SD use is

a recommendation

Humidity Range

all filters

24-hr mean 30.0% - 40.0% RH or

Within +5.0 % sampling RH but > 20.0%RH

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.2.3

Humidity Control

all filters < 5.1 % SD* over 24 hr.

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.2.4 SD use is

recommendation

Pre/post Sampling RH

all filters

difference in 24-hr means < + 5.1% RH

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.3.3

Balance all filters located in filter conditioning environment

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.3.2

Microbalance Auto-Calibration

Prior to each weighing session

Manufacturer’s specification

1) 40 CFR Part 50, App. L, Sec. 8.1

2) 40 CFR Part 50, App. L, Sec. 8.1 and Method 2.12

Sec. 10.6

3) NA

OPERATIONAL EVALUATIONS TABLE PM

2.5

Filter Based Local Conditions

Field Activities

One-point Temp Verification

every 30 days < + 2.1

o

C

1) 40 CFR Part 50, App. L, Sec. 9.3

2) Method 2.12 Sec. 7.4.5 and Table 6-1

3) Recommendation

Pressure Verification

every 30 days < + 10.1 mm Hg

1) 40 CFR Part 50, App. L, Sec. 9.3

2) Method 2.12 Sec. 7.4.6 and Table 6-1

3) Recommendation

Annual Multi-point Verifications/Calibrations

Temperature multi-point

Verification/Calibration

on installation, then every 365

days and once a calendar year

< + 2.1

o

C

1) 40 CFR Part 50, App. L, Sec. 9.3

2 and 3) Method 2.12 Sec. 6.4.4 Table 6-1

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 19 of 54

1) Criteria (PM2.5 LC) 2) Frequency 3) Acceptable Range Information /Action

Pressure Verification/Calibration

on installation, and on one-

point verification failure

< + 10.1 mm Hg

1) 40 CFR Part 50, App. L, Sec. 9.3

2 and 3) Method 2.12 Sec. 6.5

Sampler BP verified against independent standard

verified against a lab primary standard that is certified as

NIST traceable 1/year

Flow Rate Multi-point Verification/

Calibration

Electromechanical

maintenance or transport or

every 365 days and once a

calendar year

< + 2.1% of transfer standard

1) 40 CFR Part 50, App. L, Sec. 9.2.

2) 40 CFR Part 50, App. L, Sec. 9.1.3, Method 2.12

Sec. 6.3 & Table 6-1

3) Recommendation

Other Monitor Calibrations per manufacturers’ op manual per manufacturers’ operating manual 1, 2 and 3) Recommendation

Precision

Collocated Samples

every 12 days for 15% of sites

by method designation

CV < 10.1% of samples > 3.0 µg/m

3

1) and 2) Part 58 App A Sec. 3.2.3

3 Recommendation based on DQO in 40 CFR Part 58

App A Sec. 2.3.1.1

Accuracy

Temperature Audit

every 180 days and at time of

flow rate audit

< + 2.1

o

C

1, 2 and 3) Method 2.12 Sec. 11.2.2

Pressure Audit

every 180 days and at time of

flow rate audit

< +10.1 mm Hg

1, 2 and 3) Method 2.12 Sec. 11.2.3

Semi Annual Flow Rate Audit

Twice a calendar year and

between 5-7 months apart

< + 4.1% of audit standard

< + 5.1% of design flow rate

1 and 2) Part 58, App A, Sec. 3.2.2

3) Method 2.12 Sec. 11.2.1

Monitor Maintenance

PM

2.5

Separator (WINs)

every 5 sampling events

cleaned/changed 1, 2, and 3) Method 2.12 Sec. 8.2.2

PM

2.5

Separator (VSCC) every 30 days cleaned/changed 1, 2 and 3) Method 2.12 Sec. 8.3.3

Inlet Cleaning every 30 days cleaned 1, 2 and 3) Method 2.12 Sec. 8.3

Downtube Cleaning every 90 days cleaned 1, 2 and 3) Method 2.12 Sec. 8.4

Filter Housing Assembly Cleaning every 30 days cleaned 1, 2 and 3) Method 2.12 Sec. 8.3

Circulating Fan Filter Cleaning every 30 days cleaned/changed 1, 2 and 3) Method 2.12 Sec. 8.3

Manufacturer-Recommended

Maintenance

per manufacturers’ SOP per manufacturers’ SOP

Laboratory Activities

Filter Checks

Lot Blanks 9 filters per lot < +15.1 µg change between weighings

1, 2, 3) Recommendation and used to determine filter

stability of the lot of filters received from EPA or

vendor. Method 2.12 Sec. 10.5

Exposure Lot Blanks 3 filters per lot < +15.1 µg change between weighings

1, 2 and 3) Method 2.12 Sec. 10.5

Used for preparing a subset of filters for equilibration

Filter Integrity (exposed) each filter no visual defects 1, 2 and 3) Method 2.12 Sec. 10.7 and 10.3

Lab QC Checks

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 20 of 54

1) Criteria (PM2.5 LC) 2) Frequency 3) Acceptable Range Information /Action

Field Filter Blank

10% or 1 per weighing session <+ 30.1 µg change between weighings

1) 40 CFR Part 50, App. L Sec. 8.3.7.1

2 and 3) Method 2.12 Table 7-1 & Sec.10.5

Lab Filter Blank

10% or 1 per weighing session <+ 15.1 µg change between weighings

1) 40 CFR Part 50, App. L Sec. 8.3.7.2

2 and 3) Method 2.12 Sec. 10.5

Balance Check (working standards) beginning, 10th sample, end < +3.1 µg from certified value

1, 2 and 3) Method 2.12 Sec. 10.6

Standards used should meet specifications in Method

2.12, Sec. 4.3.7

Routine Filter re-weighing 1 per weighing session

<+ 15.1 µg change between weighings 1, 2 and 3) Method 2.12 Sec. 10.8

Microbalance Audit

every 365 days and once a

calendar year

<+ 0.003 mg or manufacturers specs, whichever is

tighter

1, 2 and 3) Method 2.12 Sec. 11.2.7

Lab Temp Check Every 90 days

< + 2.1

o

C 1, 2 and 3) Method 2.12 Sec. 10.10

Lab Humidity Check Every 90 days

< + 2.1% 1, 2 and 3) Method 2.12 Sec. 10.10

Verification/Calibration

Microbalance Calibration

At installation every 365 days

and once a calendar year

Manufacturer’s specification

1) 40 CFR Part 50, App. L, Sec. 8.1

2) 40 CFR Part 50, App. L, Sec. 8.1 and Method 2.12

Sec. 10.11

3) NA

Lab Temperature Certification every 365 days and once a year < + 2.1

o

C 1, 2 and 3) Method 2.12 Sec. 4.3.8 and 9.4

Lab Humidity Certification every 365 days and once a year < + 2.1% 1, 2 and 3) Method 2.12 Sec. 4.3.8 and 9.4

Calibration & Check Standards -

Working Mass Stds. Verification

Compared to primary standards

Every 90 days < + 2.1 ug

1, 2 and 3) Method 2.12 Sec. 9.7

Primary standards certification

every 365 days and once a

calendar year

0.025 mg tolerance (Class 2) 1, 2 and 3) Method 2.12 Sec. 4.3.7

SYSTEMATIC CRITERIA -PM

2.5

Filter Based Local Conditions

Siting

every 365 days and once a

calendar year

Meets siting criteria or waiver documented

1) 40 CFR Part 58 App E, Sec. 2-5

2) Recommendation

3) 40 CFR Part 58 App E, Sec. 2-5

Data Completeness

Annual Standard

> 75% scheduled sampling days in each quarter

1, 2 and 3) 40 CFR Part 50, App. N, Sec. 4.1 (b) 4.2 (a)

24- Hour Standard

> 75% scheduled sampling days in each quarter

1, 2 and 3) 40 CFR Part 50, App. N, Sec. 4.1 (b) 4.2 (a)

Reporting Units all filters

µg/m

3

at ambient temp/pressure (PM

2.5

)

1, 2 and 3) 40 CFR Part 50 App N Sec. 3.0 (b)

Rounding convention for design

value calculation

all filters

to one decimal place, with additional digits to the

right being truncated

1, 2 and 3) 40 CFR Part 50 App N Sec. 3.0 (b) The

rounding convention is for averaging values for

comparison to NAAQS not for reporting individual

values.

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 21 of 54

1) Criteria (PM2.5 LC) 2) Frequency 3) Acceptable Range Information /Action

Annual 3-yr average all concentrations

nearest 0.1 µg/m

3

(> 0.05 round up)

1, 2 and 3) 40 CFR Part 50, App. N Sec. 3 and 4

Rounding convention for data reported to AQS is a

recommendation

24-hour, 3-year average all concentrations

nearest 1 µg/m

3

(> 0.5 round up)

1, 2 and 3) 40 CFR Part 50, App. N Sec. 3 and 4

Rounding convention for data reported to AQS is a

recommendation

Detection Limit

Lower DL all filters

<

2 µg/m

3

1, 2 and 3) 40 CFR Part 50, App. L Sec. 3.1

Upper Conc. Limit all filters

> 200 µg/m

3

1, 2 and 3) 40 CFR Part 50, App. L Sec. 3.2

Precision

Single analyzer (collocated

monitors)

every 90 days

Coefficient of variation (CV) < 10.1% for values

> 3.0 µg/m

3

1, 2 and 3) Recommendation in order to provide early

(quarterly) evaluation of achievement of DQOs.

Primary Quality Assurance Org. Annual and 3 year estimates

90% CL of CV < 10.1 % for values > 3.0 µg/m

3

1, 2 and 3) 40 CFR Part 58, App A, Sec. 4.2.1 and

2.3.1.1

Bias

Performance Evaluation Program

(PEP)

5 audits for PQAOs with < 5

sites

8 audits for PQAOs with > 5

sites

< + 10.1% for values > 3.0 µg/m

3

1, 2 and 3) 40 CFR Part 58, App A, Sec. 3.2.4, 4.2.5 and

2.3.1.1

Field Activities

Verification/Calibration Standards Recertifications – All standards should have multi-point certifications against NIST Traceable standards

Flow Rate Transfer Std.

every 365 days and once a

calendar year

< + 2.1% of NIST Traceable Std.

1) 40 CFR Part 50, App. L Sec. 9.1 & 9.2

2) Method 2-12 Sec. 4.2.2 & 6.4.3

3) 40 CFR Part 50, App. L Sec. 9.1 & 9.2

Field Thermometer

every 365 days and once a

calendar year

+ 0.1

o

C resolution, + 0.5

o

C accuracy

1, 2 and 3) Method 2.12 Sec. 4.2.2

Field Barometer

every 365 days and once a

calendar year

+ 1 mm Hg resolution, + 5 mm Hg accuracy

1, 2 and 3) Method 2.12 Sec. 4.2.2

Clock/timer Verification Every 30 days

1 min/mo

1 and 2) Method 2.12 Sec. 4.2.1

3) 40 CFR Part 50, App. L Sec. 7.4.12

Laboratory Activities

Microbalance Readability At purchase 1 µg

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.1

Microbalance Repeatability At purchase 1 µg

1) Method 2.12 Sec. 4.3.6

2) Recommendation

3) Method 2.12 Sec. 4.3.6

Primary Mass/Working mass

Verification/Calibration Standards

At purchase 0.025 mg tolerance (Class 2)

1, 2 and 3) Method 2.12 Sec. 4.3.7

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 22 of 54

1) Criteria (PM2.5 LC) 2) Frequency 3) Acceptable Range Information /Action

Comment #1

The associated leak test procedure shall require that for successful passage of this test, the difference between the two pressure measurements shall not be greater than the number of mm

of Hg specified for the sampler by the manufacturer, based on the actual internal volume of the sampler, that indicates a leak of less than 80 mL/min.

1/ value must be flagged SD * = standard deviation CV= coefficient of variation

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 23 of 54

Continuous PM2.5 Local Conditions Validation Template

NOTE: This validation template attempts to provide the critical criteria, annual multipoint verifications/calibrations, and verification/calibration standards recertification

frequencies and acceptable ranges for PM2.5 continuous FEMs and ARMs. At the time this validation template was most recently updated (January 2016) there were

eleven continuous monitors designated as a Federal Equivalent Method (FEM) and none designated as an Approved Regional Method (ARM). For the most widely used

continuous FEMs we have added select method specific operational criteria. However, due to limited available information, we do not have operational criteria for all

approved FEMs, especially those methods with just a handful or less of monitors that have been implemented. Where we do list operational criteria for a specific method,

we only list the criteria believed to be the most important. More detailed information on operational criteria is available for the most widely used PM2.5 continuous

FEMs in Technical System Audit Supplementary Checklists for PM Continuous Monitors. These files are available on the web at:

https://www3.epa.gov/ttn/amtic/contmont.html.

Technical Systems Audit Checklists

PM continuous TSA checklist – Met One BAM – Draft (PDF)

PM continuous TSA checklist – Thermo TEOM-FDMS – Draft (PDF)

Where appropriate, 40 CFR Part 58 App A and 40 CFR Part 50 App L requirements apply to Continuous PM2.5 FEMs; however, not all criteria may apply to each

continuous FEM and ARM due to the nature of the measurement principle and design of the instrument. Also, while this validation template is designed to apply to

PM2.5 continuous FEMs and ARMs, it may also apply to PM2.5 continuous methods that are not specifically approved as FEMs or ARMs and used to meet SLAMS

monitoring requirements in support of the AQI, but not the NAAQS.

1) Criteria (PM2.5 Cont) 2) Frequency 3) Acceptable Range Information /Action

CRITICAL CRITERIA- PM

2.5

Continuous, Local Conditions

Sampler/Monitor Designation

NA

Meets requirements listed in FRM/FEM/ARM

designation

Confirm method designation on front panel or just inside

instrument.

1) 40 CFR Part 58 App C Sec. 2.1

2) NA

3) 40 CFR Part 53 & FRM/FEM method list

Firmware of monitor At setup

1. Must be the firmware (or later version) as identified

in the published method designation summary.

2. Firmware settings must be set for flowrate to

operate and report at “local conditions” (i.e., not

STP).

40 CFR Part 50 App N. sec. 1 (c)

Data Reporting Period Report every hour

1. The calculation of an hour of data is dependent on the

design of the method.

2. A 24-hour period is calculated in AQS if 18 or more

valid hours are reported for a day

1/

.

See operator’s manual. Hourly data are always

reported as the start of the hour on local standard

time

40 CFR Part 50 App N. Sec 3 (c)

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 24 of 54

1) Criteria (PM2.5 Cont) 2) Frequency 3) Acceptable Range Information /Action

Sampling Instrument

PM10 Inlet (if applicable to method

designated)

At Setup

Must be a Louvered PM10 size selective inlet as specified

in 40 CFR 50 appendix L, Figures L-2 through L-19

PM2.5 second stage separator (if

applicable to method designated)

At Setup

Must be a BGI Inc. Very Sharp Cut Cyclone (VSCC

TM

) or

equivalent second stage separator approved for the

method.

The other approved second stage separator option

for select FEMs is the Dichot. Only the GRIMM

180 and Teledyne T640 and T640X are known to

not have a second stage seperator as part of the

method.

Average Flow Rate

every 24 hours of operation;

alternatively, each hour can be

checked

average within 5% of 16.67 liters/minute at local

conditions

1, 2 and 3) Part 50 App L Sec. 7.4.3.1

Variability in Flow Rate every 24 hours of op CV < 2%

1, 2 and 3) 40 CFR Part 50, App L Sec. 7.4.3.2

One-point Flow Rate Verification

every 30 days each seperated

by 14 days

< + 4.1% of transfer standard

< + 5.1% of flow rate design value

1, 2 and 3) 40 CFR Part 50, App.L, Sec. 9.2.5, 40

CFR Part 58, Appendix A Sec. 3.2.3 & 3.3.2

Design Flow Rate Adjustment

After multi-point calibration or

verification

< + 2.1% of design flow rate

1,2 and 3) 40 CFR Part 50, App. L, Sec. 9.2.6

External Leak Check

Before each flow rate

verification/calibration and

before and after PM

2.5

separator

maintenance

Method specific. See operator’s manual.

1) 40 CFR Part 50 App L, Sec. 7.4.6.1

2) 40 CFR Part 50 App L Sec.t 9.2.3 and Method

2-12 Sec. 7.4.3

3) 40 CFR Part 50, App. L, Sec. 7.4.6.1

Internal Leak Check

If failure of external leak check Method specific. See operators manual.

1) 40 CFR Part 50, App. L, Sec. 7.4.6.2

2) Method 2-12 7.4.4

3) 40 CFR Part 50, App. L, Sec. 7.4.6.2

Annual Multi-point Verifications/Calibrations

Leak Check

every 30 days

< 1.0 lpm BAM (Not Thermo BAMS)

+ 0.15 lpm TEOM

1) 40 CFR Part 50 App L, Sec. 7.4.6.1

2) Recommendation

3) BAM SOP Sec. 10.1.2

TEOM SOP Sec. 10.1.6

Thermo BAM leak check should not be attempted.

Foils could be ruptured.

Temperature multi-point

Verification/Calibration

on installation, then Every 365

days and 1/ calendar year

< + 2.1

o

C

1) 40 CFR Part 50, App.L, Sec. 9.3

2 and 3) Method 2.12 Sec. 6.4.4

One-point Temp Verification

every 30 days < + 2.1

o

C

1) 40 CFR Part 50, App.L, Sec. 9.3

2) Method 2.12 Sec. 7.4.5 and Table 6-1

3) Recommendation

Pressure Verification/Calibration

on installation, then Every 365

days and 1/ calendar year

< + 10.1 mm Hg

1) 40 CFR Part 50, App.L, Sec. 9.3

2 and 3) Method 2.12 Sec. 6.5

BP verified against independent standard verified

against a lab primary standard that is certified

NIST traceable 1/year

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 25 of 54

1) Criteria (PM2.5 Cont) 2) Frequency 3) Acceptable Range Information /Action

Flow Rate Multi-point Verification/

Calibration

Electromechanical

maintenance or transport or

Every 365 days and 1/ calendar

year

< + 2.1% of transfer standard

1) 40 CFR Part 50, App.L, Sec. 9.2.

2) 40 CFR Part 50, App.L, Sec. 9.1.3, Method 2.12

Sec. 6.3 & Table 6-1

3) Recommendation

Other Monitor Calibrations/checks per manufacturers’ op manual

Annual zero test on Met One BAM 1020 and BAM 1022

per manufacturers’ operating manual. Note: more

frequent zero tests may be appropriate in areas with

seasonal changes in dew-points.

Precision

Collocated Samples

every 12 days for 15% of sites

by method designation

CV < 10.1% of samples > 3 µg/m

3

1) and 2) Part 58 App A Sec. 3.2.3

3 Recommendation based on DQO in 40 CFR Part

58 App A Sec. 2.3.1.1

Accuracy

Temperature Audit

every 180 days and at time of

flow rate audit

< + 2.1

o

C

1, 2 and 3) Method 2.12 Sec. 11.2.2

Pressure Audit

every 180 days and at time of

flow rate audit

< +10.1 mm Hg

1, 2 and 3) Method 2.12 Sec. 11.2.3

Semi Annual Flow Rate Audit

Twice a calendar year and 5-7

months apart

< + 4.1% of audit standard

< + 5.1% of design flow rate

1 and 2) Part 58, App A, Sec. 3.3.3

3) Method 2.12 Sec. 11.2.1

Shelter Temperature

Temperature range At setup per operator manual

Temperature Control Daily (hourly values) < 2.1

o

C SD over 24 hours 1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Temperature Device Check

every 180 days and twice a

calendar year

< + 2.1

o

C

1, 2 and 3) QA Handbook Volume 2 Sec. 7.2.2

Monitor Maintenance

PM

2.5

Separator (WINS)

every 5 sampling events

cleaned/changed 1, 2,and 3) Method 2.12 Sec. 8.2.2

PM

2.5

Separator (VSCC) every 30 days cleaned/changed 1,2 and 3) Method 2.12 Sec. 8.3.3

Inlet Cleaning every 30 days cleaned 1,2 and 3) Method 2.12 Sec. 8.3

Downtube Cleaning every 90 days cleaned 1,2 and 3) Method 2.12 Sec. 8.4

Filter Housing Assembly Cleaning every 30 days cleaned 1, 2 and 3) Method 2.12 Sec. 8.3

Circulating Fan Filter Cleaning every 30 days cleaned/changed 1, 2 and 3) Method 2.12 Sec. 8.3

Manufacturer-Recommended

Maintenance

per manufacturers’ SOP per manufacturers’ SOP

TEOM-FDMS Specific Operational Criteria

Total Flow Verification every 30 days

Sum of flow rates from 3 paths equal design

flow rate < + 5.1%

1,2 and 3) TEOM SOP Sec. 10.1.2

Bypass leak check (TEOM) every 30 days + 0.60 lpm

1,2 and 3) TEOM SOP Sec. 10.1.6 or TEOM

Operating Manual Sec. 5-4

Replace TEOM filters as needed

Change TEOM filter as filter loading approaches 90%, but

must be changed before reaching 100%.

1,2 and 3) TEOM SOP Sec. 10.1.8

Replace the 47-mm FDMS (Purge)

filters

every 30 days or any time

TEOM filters are replaced

replaced

1,2 and 3) TEOM SOP Sec. 10.1.10

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 26 of 54

1) Criteria (PM2.5 Cont) 2) Frequency 3) Acceptable Range Information /Action

Internal/External Data Logger Data

Every 30 days

10 randomly selected values

agree exactly (digital) and + 1 µg/m

3

(analog). Note:

digital is expected and should be used unless there is no

capacity to utilize digital in the monitoring agencies’ data

system.

1, 2 and 3) TEOM SOP Sec. 10.1.24

Replace In-line filters

every 180 days and twice a

calendar year

replaced

1, 2 and 3) TEOM SOP Sec. 10.2

Clean cooler assembly

every 365 days and once a

calendar year

cleaned

1, 2 and 3) TEOM SOP Sec. 10.3.1

Clean/Maintain switching valve

every 365 days and once a

calendar year

cleaned

1, 2 and 3) TEOM SOP Sec. 10.3.2

Clean air inlet system of mass

transducer enclosure

every 365 days and once a

calendar year

cleaned

1, 2 and 3) TEOM SOP Sec. 10.3.3

Replace the dryers 1/yr or due to poor performance

Review dryer dew point data to determine acceptable

performance of dryer

1, 2 and 3) TEOM SOP Sec. 10.3.4

Calibration (KO) constant

verification

every 365 days and once a

calendar year

Pass or Fail

(< 2.5%)

1, 2 TEOM SOP Sec. 10.3.6

3) 1405-DF operating guide. Verification software

either passes or fails the verification. Acceptance

criteria is < 2.5 %

Rebuild sampling pump 18 months < 66% of local pressure 1, 2 and 3) TEOM SOP Sec. 10.4

GRIMM Specific Operational Criteria

Internal rinsing air filter After a few years Changed

1, 2 and 3) GRIMM SOP Sec. 12.4

May require a trained service staff to change. May

only require changing if a message reads “check

nozzle and air inlet”

Change Dust Filter

Every 365 days and 1/ calendar

year

Changed

1, 2 and 3) GRIMM SOP Sec. 12.3

Relative Humidity Setting At Setup

Per Operators manual (55%) unless otherwise directed

and approved to use at a different value

Calibration of spectrometer Yearly +/- 5% for mass Operators’ Manual section 5.2

Cleaning or changing of the Nafion

in inlet

As needed We are seeking clarification from GRIMM on this Operators’ Manual section 11.4.2

Thermo BAM Specific Operational Criteria

Cleaning Nozzle and Vane (BAM) Minimally every 30 days cleaned

1, 2 and 3) BAM SOP Sec. 10.1.3

Leak Check every 30 days < 0.42 L/min

1) BAM 5014i Instruction Manual

2)

3) BAM 5014i Instruction Manual

Replace or clean pump muffler

every 180 days and twice a

calendar year

Cleaned or changed

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 27 of 54

1) Criteria (PM2.5 Cont) 2) Frequency 3) Acceptable Range Information /Action

Internal/External Data Logger Data

(BAM)

Every 30 days

10 randomly selected values

agree exactly (digital) and + 1 µg/m

3

(analog). Note:

digital is expected and should be used unless there is no

capacity to utilize digital in the monitoring agencies’ data

system.

1, 2 and 3) BAM SOP Sec. 10.1.9

Clean/replace internal debris filter

Every 365 days and 1/ calendar

year

MetOne BAM Specific Operational Criteria

BAM check of membrane span foil Daily Avg. < + 5.1% of ABS

1, 2 and 3) BAM SOP Sec. 10.4.3. Applies on the

BAM 1020

BAM electrical grounding At setup

1. Is the chassis of the BAM grounded?

Is the downtube grounded to the chassis at the collar (i.e.,

with setscrews)

Per operator manual

Nozzle cleaning

Every 30 days, or more often as

needed

cleaned Per operator manual

Zero test Yearly

Standard deviation of the data from a 72-hour zero test

< 2.4 µg/m

3

Per operator manual

SYSTEMATIC CRITERIA- PM

2.5

Continuous, Local Conditions

Siting

every 365 days and once a

calendar year

Meets siting criteria or waiver documented

1) 40 CFR Part 58 App E, Sec. 2-5

2) Recommendation

3) 40 CFR Part 58 App E, Sec. 2-5

Data Completeness Annual Standard > 75% scheduled sampling days in each quarter

1, 2 and 3) 40 CFR Part 50, App. N, Sec. 4.1 (b)

4.2 (a)

24- Hour Standard > 75% scheduled sampling days in each quarter

1, 2 and 3) 40 CFR Part 50, App. N, Sec. 4.1 (b)

4.2 (a)

Reporting Units all filters

µg/m

3

at ambient temp/pressure (PM

2.5

)

1. 2 and 3) 40 CFR Part 50 App N Sec. 3.0 (b)

Rounding convention for data

reported to AQS

all filters to one decimal place or as reported by instrument

1. 2 and 3) 40 CFR Part 50 App N Sec. 3.0 (b)

Annual 3-yr average all concentrations

nearest 0.1 µg/m

3

(> 0.05 round up)

1,2 and 3) 40 CFR Part 50, App. N Sec. 3 and 4

Rounding convention for data reported to AQS is a

recommendation

24-hour, 3-year average all concentrations

nearest 1 µg/m

3

(> 0.5 round up)

1,2 and 3) 40 CFR Part 50, App. N Sec. 3 and 4

Rounding convention for data reported to AQS is a

recommendation

Verification/Calibration Standards Recertifications - All standards should have multi-point certifications against NIST Traceable standards

Flow Rate Transfer Std.

every 365 days and once a

calendar year

< + 2.1% of NIST Traceable Std.

1) 40 CFR Part 50, App.L Sec. 9.1 & 9.2

2) Method 2-12 Sec. 4.2.2 & 6.4.3

3) 40 CFR Part 50, App.L Sec. 9.1 & 9.2

Field Thermometer

every 365 days and once a

calendar year

+ 0.1

o

C resolution, + 0.5

o

C accuracy

1, 2 and 3) Method 2.12 Sec. 4.2.2

QA Handbook Volume II, Appendix D

Revision No 1

Date:03/17

Page 28 of 54

1) Criteria (PM2.5 Cont) 2) Frequency 3) Acceptable Range Information /Action

Field Barometer

every 365 days and once a

calendar year

+ 1 mm Hg resolution, + 5 mm Hg accuracy

1, 2 and 3) Method 2.12 Sec. 4.2.2

Clock/timer Verification Every 30 days

1 min/mo**

1 and 2) Method 2.12 Sec. 4.2.1

3) 40 CFR Part 50, App.L Sec. 7.4.12

Precision

Single analyzer (collocated

monitors)

every 90 days

Coefficient of variation (CV) < 10.1% for values > 3.0

µg/m

3

1,2 and 3) Recommendation in order to provide

early (quarterly) evaluation of achievement of

DQOs.

Primary Quality Assurance Org. Annual and 3 year estimates

90% CL of CV < 10.1 % for values > 3.0 µg/m

3

1,2 and 3) 40 CFR Part 58, App A, Sec. 4.2.1 and

2.3.1.1

Bias

Performance Evaluation Program

(PEP)

5 audits for PQAOs with < 5

sites

8 audits for PQAOs with > 5

sites

< +10.1% for value > 3 µg/m

3

1,2 and 3) 40 CFR Part 58, App A, Sec. 3.2.7, 4.3.2

and 2.3.1.1

1/ 24 hour average value must be flagged if not meeting criteria

SD= standard deviation , CV= coefficient of variation

** = need to ensure data system stamps appropriate time period with reported sample value

QA Handbook Volume II, Appendix D

Revision No. 1

Date:03/17

Page 29 of 54

PM10c for PM

10-2.5

Low –Volume, Filter-Based Local Conditions Validation Template

NOTE: The following validation template was constructed for use of PM

10

at local conditions where PM

10c

is used in the calculation of the PM

10-2.5

measurement or for

objectives other than comparison to the PM

10

NAAQS. Although the PM

10-2.5

method is found in 40 CFR Part 50 Appendix O, Appendix O references Appendix L (the

PM

2.5

Method) for the QC requirements listed below. Therefore, the information action column, in most cases, will reference 40 CFR Part 50 App L. Monitoring

organizations using PM

10

data for a NAAQS comparison purposes should refer to the PM

10

validation template for STP (standard temperature and pressure correction).

In addition, since the samplers are very similar to the PM2.5 samplers, Guidance Document 2.12 Monitoring PM2.5 in Ambient Air Using Designated Reference or Class

1 Equivalent Methods is referred to where appropriate.

1) Criteria (PM10c) 2) Frequency 3) Acceptable Range Information /Action

CRITICAL CRITERIA- PM10c Filter Based Local Conditions

Field Activities

Sampler/Monitor

NA

Meets requirements listed in FRM/FEM/ARM

designation

1) 40 CFR Part 58 App C Sec. 2.1

2) NA

3) 40 CFR Part 53 & FRM/FEM method list

Filter Holding Times

Pre-sampling all filters < 30 days before sampling

1, 2 and 3) 40 CFR Part 50, App. L Sec. 8.3.5

Sample Recovery all filters <7 days 9 hours from sample end date

1, 2 and 3) 40 CFR Part 50 App L Sec. 10.10

Sampling Period (including