INTRODUCTION

The Indian government is introducing Bharat Stage VI (BS-VI)

emissions standards (equivalent to Euro VI standards) from 2020,

completely by-passing Stage V standards. For commercial vehicles

with diesel engines, these standards will reduce the NOx emissions

by 88% and Particulate Matter (PM) emissions by 66% from current

BS IV standards. Table 1 shows tailpipe emissions and test cycles for

BS IV and BS VI emissions standards [1].

Table 1. Tailpipe emissions standards for India.

Achieving Bharat Stage VI Emissions Regulations While Improving Fuel

Economy with the Opposed-Piston Engine

Suramya Naik, David Johnson, Laurence Fromm, John Koszewnik, Fabien Redon,

Gerhard Regner, and Neerav Abani

Achates Power, Inc.

ABSTRACT

The government of India has decided to implement Bharat Stage VI (BS-VI) emissions standards from April 2020. This requires OEMs

to equip their diesel engines with costly after-treatment, EGR systems and higher rail pressure fuel systems. By one estimate, BS-VI

engines are expected to be 15 to 20% more expensive than BS-IV engines, while also suffering with 2 to 3 % lower fuel economy.

OEMs are looking for solutions to meet the BS-VI emissions standards while still keeping the upfront and operating costs low enough

for their products to attract customers; however traditional engine technologies seem to have exhausted the possibilities. Fuel economy

improvement technologies applied to traditional 4-stroke engines bring small benets with large cost penalties.

One promising solution to meet both current, and future, emissions standards with much improved fuel economy at lower cost is

the Opposed Piston (OP) engine. Recently, there has been surge in developing highly efcient OP engine architecture to

modernize it using today’s analytical tools, high pressure fuel system and manufacturing technologies to meet emissions, while

reaping the fuel economy advantage.

As the company pioneering the OP engine technology, Achates Power Inc. (API) has been publishing technical papers in recent years,

including a paper describing inherent efciency benets of OP engines, multi-cylinder steady state and transient results for medium

duty truck and light duty applications. This technical paper provides detailed performance and emissions results measured on API’s

4.9L multi-cylinder OP 2-stroke diesel engine congured specically to meet BS-VI emissions standards for commercial truck

application. The results include:

• Measured performance and emissions data for emissions test cycles.

• After-treatment details and conrmation to meet tailpipe emissions for BS-VI standards.

• Details of API’s multi-cylinder test engine’s indicated thermal efciency, friction and pumping losses.

• Comparison with 4-stroke diesel engine.

CITATION: Naik, S., Johnson, D., Fromm, L., Koszewnik, J. et al., "Achieving Bharat Stage VI Emissions Regulations While Improving

Fuel Economy with the Opposed-Piston Engine," SAE Int. J. Engines 10(1):2017, doi:10.4271/2017-26-0056.

2017-26-0056

Published 01/10/2017

Copyright © 2017 SAE International

doi:10.4271/2017-26-0056

saeeng.saejournals.org

17

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017

While these steps will help reducing pollution from vehicles, it will

require costly additional after-treatment devices such as Diesel

Particulate Filters (DPF) for trapping exhaust particulate matters and

Selective Catalytic Reduction (SCR) for treating engine-out NOx

with aqueous urea solution. Additionally, the engine will require

Exhaust Gas Recirculation (EGR) system (EGR valve, cooler etc.)

for reducing engine-out NOx with upgraded turbocharger. The Diesel

fuel system will also have to be upgraded for higher injection

pressures to reduce engine out particulates. As per one estimate done

by International Council for Clean Transportation, the additional

hardware required to upgrade 2.5 L 4-cylinder light duty diesel

engines from Euro IV to Euro VI is expected to increase the cost of

the engine by $1134 [2]. For 12 L truck engine, this expected cost is

$2740 [3]. Even with all cost cutting measures, this increased cost

translates into 15 to 20% more expensive engines for BS VI vehicles.

Not only the costs of the engines will increase signicantly for

meeting BS VI emissions, the fuel consumption will also get

adversely affected because of the following reasons:

• Increased exhaust back pressure resulting from more restrictive

after-treatment system together with high intake manifold

pressure requirements for BS VI engine increase pumping losses.

• Higher EGR requirements also increase pumping losses

especially as the recirculated exhaust gas has to pass through

restrictive coolers.

• Higher fuel injection pressure requirements result in increased

power loss to the fuel pump.

• Increased Peak Cylinder Pressures (PCP) due to higher air and

EGR requirements increase friction penalties.

Because of the above mentioned reasons, the BSFC is expected to

increase at least 2 to 3% without using additional fuel-saving

technologies for BS VI engines in comparison to BS IV engines [4].

With 4-stroke fuel saving technologies proving to be less cost effective

in providing improved fuel economy [3][4], there is a serious need for

the industry to search for fundamentally better engines. Opposed

Piston (OP) engines have been historically more fuel efcient and

have potential for reducing engine cost because of simpler architecture

and less number of parts [5][8]. These engines are now being

investigated by major OEMs around the world as a solution for

reducing fuel consumption at lower cost for modern vehicles [6].

Achates Power, Inc. (API), a US based company has been working

since 2004 towards developing OP engine technology using today’s

analytical and manufacturing technologies. Through numerous

technical papers, API has explained advantages of its OP engines

such as reduced heat losses; leaner, faster and earlier combustion; and

higher turbulent kinetic energy at the start of injection with its

proprietary piston bowl and two opposing injectors in each cylinder

[7][8][10]. API has also explained practical considerations for various

applications [8] and demonstrated improved fuel economy while

meeting strict engine-out emissions on steady state basis on its

multi-cylinder OP 2-stroke research engine [9][10]. This paper

describes further investigations on API’s multi-cylinder research

engine for BS VI emission standards.

MULTI-CYLINDER OP 2-STROKE

RESEARCH ENGINE

Details of API’s 4.9 L 3-cylinder OP 2-Stroke engine are shown in

Table 2 below.

Table 2. Multi-cylinder Achates Power OP 2-Stroke engine specification.

API’s 4.9 L 3-cylinder engine has been designed and developed

internally for carrying out research and developing OP engine

technology before developing production engines with customers.

Therefore, it is designed with higher safety margin components to

allow investigations for different applications. It is also designed to

disassemble quickly and is built with modular components that are

switchable. Moreover, this engine has off-the-shelf components

without customization, primarily because this engine is not

production intent and parts customization costs were unnecessary. All

of these factors however, result in higher friction and pumping loss

penalties than will be measured on optimized and customized

production OP engines.

The air system layout together with on-engine measurement sensors

for this particular conguration of the API multi-cylinder engine is

described in gure 1.

Figure 1. API 4.9L research engine air system configuration & sensor layout.

As seen from the gure 1, API’s 3-cylinder inline OP 2-Stroke engine

research has turbocharger and a supercharger. It has high pressure

EGR system with one intercooler between turbo and supercharger,

Naik et al / SAE Int. J. Engines / Volume 10, Issue 1 (February 2017)

18

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017

and two small air coolers downstream of supercharger. There are also

provisions for supercharger recirculation, 2-speed supercharger drive

and wastegate for the xed geometry turbocharger. Main advantage

of this air system include lower pumping losses, faster transient

response and improved cold start & warm-up performance [8][10].

Figure 2. Rear view of API 4.9L research engine on cart.

Figure 2 shows the rear view of API’s 4.9 L research engine on the

cart ready to be tested on engine dynamometer. More details of the

API OP research engine hardware and test cell conguration has been

published before in literature [9].

A standard diesel after-treatment system for heavy duty engine with

Diesel Oxidation Catalyst (DOC), Diesel Particulate Filters (DPF),

Selective Catalytic Reduction (SCR) and Ammonia Slip Catalyst

(ASC) has been assumed for meeting BSVI emissions standards. The

SCR is assumed to have NOx conversion efciency of 90% and

therefore the engine out NOx target for WHSC is less than 4 g/kWh.

The engine out soot target for WHSC cycle is set to be less than

0.025 g/kWh to allow for passive regen of particulate lter during

real world driving with low pressure drop. It is assumed that BSIV

engine may only have Particulate Oxidation Catalyst (POC) like

device in the after-treatment and therefore the engine out NOx for

ESC cycle is same as vehicle out (less than 3.5 g/kWh) - which turns

out to be only slightly lower to engine out NOx requirements for

BSVI engine with full after-treatment.

STEADY STATE TEST RESULTS

The API 3-cylinder research engine torque curve for truck application

together with ESC and WHSC points are shown in the gure 3.

Figure 3. API 4.9L research engine torque curve for truck application with

ESC and WHSC points.

As seen from gure 3, the WHSC cycle points are heavily weighted

in the low speed and low load region of the torque curve compared to

the ESC points. This justies using of different turbocharger to

improve BSFC at lower load and lower speed region for BS VI

emissions. However, the engine data was measured for both ESC 13

mode and WHSC points on same air system described earlier.

API has developed control strategy for addressing the challenges of

the OP 2-stroke engines. As seen from gure 1, supercharger 2-speed

drive and supercharger recirculation valve are two main actuators for

controlling air ow; while EGR valve is used for controlling EGR

ow. Air massow is accurately measured with MAF sensor located

upstream of the compressor, while EGR massow is measured with

venturi and deltaP sensor in the EGR path. The M470 rapid

prototyping open ECU from Pi Innovo has been programmed to

allow for ring two injectors simultaneously in one cylinder.

The detailed results of the steady state measurements are shown in

the Appendix A. The results show OP engine’s high indicated thermal

efciency over the entire engine map. The friction loss for the 4.9L

research engine is higher than production version engines as

explained earlier. Pumping losses over the engine map are reasonable

even with off-the-shelf air system components.

Summary of steady state cycle averaged results are shown in table 3

below. With optimized air system for better BSFC at lower load and

speed operating conditions - as required for the WHSC cycle - the

cycle averaged BSFC can be reduced about 2 to 4 g/kWh.

Table 3. Summary of ESC and WHSC cycle results.

Naik et al / SAE Int. J. Engines / Volume 10, Issue 1 (February 2017)

19

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017

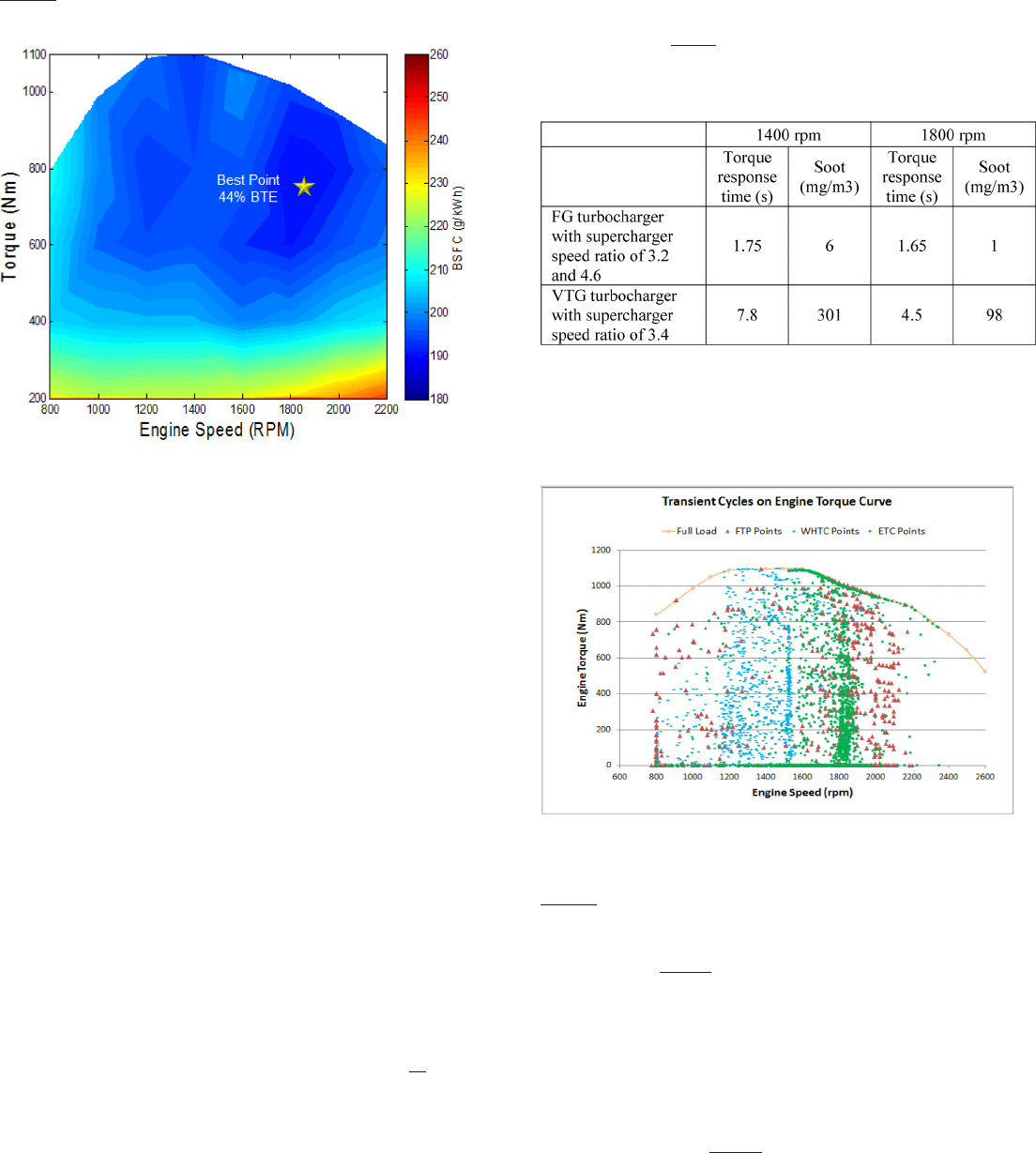

Figure 4 shows BSFC map of API’s 4.9 L research engine from these

steady state measured results.

Figure 4. BSFC map from steady state measured data on API research engine.

TRANSIENT CONTROLS AND TEST RESULTS

Compared to the controls software for steady state calibration, the

transient operation of the engine need strategy for limiting smoke

during acceleration; and for faster actuator response for driving air

and EGR. The 4.9L research engine controls strategy was improved

with a smoke limiter algorithm and feed-forward controllers for air

and EGR actuators.

The smoke limiter algorithm essentially is limiting the amount of fuel

that can be injected in the cylinder during acceleration as the air

handling devices (turbocharger and supercharger) respond slower

than the fuel system. Rail pressure modier was also implemented for

increasing rail pressure during transient.

For increasing airow during acceleration, EGR valve is closed to

allow for more massow through turbine for reducing turbo lag. For

supercharger, rst the recirculation valve is closed; if the airow

demand is still not met (or in conditions where the recirculation valve

is already fully closed for the starting point), the supercharger

2-speed drive is switched to higher drive ratio. With smoke limiter

implemented and higher supercharger drive ratio, the engine was able

to achieve the full load torque from 25% load at constant speed

within 1.5 seconds with minimal NOx and soot spikes. The torque

response time and emissions results for different supercharger drive

ratios for OP engine have been discussed in detailed earlier [13].

The 4.9 L research engine was also investigated for transient response

with Variable Turbine Geometry (VTG) turbocharger and single gear

ratio supercharger. A comparison of VTG turbo with single drive

supercharger and xed geometry turbo with 2-speed supercharger for

transient response for 1 second torque ramps at two different engine

speeds is shown in table 4 below.

Table 4. Transient response comparison of VTG turbocharger and single speed

supercharger Vs FG turbocharger and 2-speed supercharger.

As seen from the results, the supercharger 2-speed drive is improving

the transient response of the OP 2-stroke engine signicantly. With

developed transient controls, the 4.9 L research engine was put on

test for transient emissions cycle.

Figure 5. US heavy-duty FTP together with European ETC and WHTC cycles

operating points on API 4.9L research engine torque curve.

Figure 5 shows engine operating conditions for three transient cycles

- US heavy duty FTP, WHTC and ETC plotted with the torque curve.

As seen from the gure 5, the ETC cycle operates heavily around

1800 rpm for API 4.9L engine (on the higher engine speed region

similar to ESC cycle), while the WHTC cycle is weighted more in the

region of 1500 rpm (relatively lower engine speed region similar to

WHSC cycle). Though the engine operates more in the speed range

of 1700 to 2200 rpm for the heavy duty FTP cycle for US 2010

emissions, this transient cycle has wider speed range and larger speed

gradients. Also, it is designed for both city as well as highway driving

conditions as seen in the gure 6 with New-York Non-Freeway

(NYNF), Los Angeles Non-Freeway (LANF) and Los Angeles

Freeway (LAFY) segments. Therefore heavy duty FTP was selected

for testing transient capabilities of the 4.9 L research engine.

Naik et al / SAE Int. J. Engines / Volume 10, Issue 1 (February 2017)

20

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017

Figure 6. US heavy-duty FTP cycle with NYNF, LANF and LAFY segments [16].

During the transient testing, engine speed, torque and power

requirements were appropriately matched with the targets to meet the

heavy duty FTP cycle requirements. Statistically, the R

2

values of the

measured speed, torque and power compared to the targets were 0.97,

0.94 and 0.98 respectively - within the range specied by the

regulations. The heavy duty transient cycle averaged values of BSFC,

BSNOx and BSSoot were measured to be 217.3 g/kWh, 4.3 g/kWh and

0.056 g/kWh respectively. When compared with the BSFC map data

generated from the steady state measurements, the transient BSFC is

only 2.1 g/kWh higher - suggesting that the controls strategies are

working decently as required for such application. Detailed description

and results of the US 2010 heavy duty transient test for API’s 4.9L

engine have been published in 2016 SAE paper [11].

Additional to transient controls, API has also developed warm-up

strategies for catalyst light off, details of which have been published

in other papers [10][13].

CONFIRMING TAILPIPE EMISSIONS

API teamed up with Johnson Matthey - a leading after-treatment

supplier to check if the tailpipe emissions of its 4.9L OP engine meet

stringent BSVI standards. Johnson Matthey has developed a patented

SCRT

®

aftertreatment system (ATS) which allows for passive

regeneration of particulate lter using higher engine out NOx, and

SCR to reduce the NOx [12].

The system has DOC with platinum group metals (PGM) as rst

component to oxidize HC and CO, also to convert NO to NO

2

that

helps with passive regen of particulate lter. Second component is

Catalyst Soot Filter (CSF) for removing PM. Urea is injected after

CSF and before SCR to remove NOx emissions. And nally, ASC is

used to oxidize access NH

3

. Figure 7 shows schematic of Johnson

Matthey’s patented SCRT

®

aftertreatment system.

Figure 7. Johnson Matthey’s SCRT

®

aftertreatment system [12].

This system was sized for reasonable space velocities through its

components and simulated with chemistry models by Johnson

Matthey engineers to check its performance for 13 mode steady state

engine out exhaust from API’s 4.9L research engine. Full details of

the study have been published in 2016 emissions conference paper

[12]. The details of the various ATS components size and structure

are shown below in gure 8.

Figure 8. Simulated ATS components volume, CPSI/wall thickness and PGM

loading [12].

To check for possibilities of passive regeneration of CSF, the DOC

was simulated for two cases -

Case 1. Low Pt:Pd (2:1) ratio aged at 780

0

C/10h and

Case 2. High Pt:Pd (5:1) ratio aged at 780

0

C/100h [12].

The 100 repetitions of 13 mode steady state cycle results show that

for case 2, the DOC would remove THC and CO 92 and 100%

respectively [12]. CSF would go through sufcient passive

regeneration to stabilize at 1.3 g/L soot loading after 100 ESC tests

[12]. The NOx conversion efciency of 96% can be achieved with

the SCR [12]. The maximum pressure drop through this ATS for the

steady state cycle simulations is 15 kPa for 0 g/l soot in CSF and 16.5

kPa for 3 g/l soot loading in CSF. Table 5 below show cycle averaged

tailpipe emissions for 13 points of the ESC test [12].

Naik et al / SAE Int. J. Engines / Volume 10, Issue 1 (February 2017)

21

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017

Table 5. Summary of Johnson Matthey ATS simulation results on API’s 4.9L

engine out cycle-averaged emissions for 13 points of ESC cycle [12].

Results of steady state cycles operating points listed in Appendix A

show that the turbine out temperatures of the exhaust for all of the

WHSC points except idle range between 250 to 368

0

C which is

similar to the range of 236 to 357

0

C seen on the ESC cycle points.

Therefore, even though the aftertreatment simulations were carried

out on 100 cycles of the 13-modes of ESC test, simulating the WHSC

operating points with after-treatment should also be able to meet the

tailpipe emissions targets.

The same aftertreatment system was also simulated by Johnson

Matthey engineers for heavy-duty transient FTP cycle data measured

on 4.9 L research engine. Figure 9 below show space velocities

through different ATS components and inlet temperature for the

heavy-duty FTP cycle.

Figure 9. Space velocities through different ATS components and inlet

temperature for the heavy-duty FTP cycle.

As seen from gure 9, the ATS inlet gas temperature varies between

160 to 300

0

C. The maximum pressure drop of the entire ATS for the

heavy-duty FTP cycle simulation was 10.4 kPa for 0 g/l soot

loading and 12.1 kPa for 3 g/l soot loading. Table 6 below show

emissions conversion efciencies achieved during the heavy-duty

FTP cycle simulations.

Table 6. Summary of Johnson Matthey aftertreatment system simulation

results on API’s 4.9L engine out exhaust for heavy-duty FTP transient cycle.

These ATS system simulations for steady state and transient cycles

with measured engine out emissions and exhaust temperatures

conrm that API’s 4.9 L engine will meet BSVI tailpipe emissions.

COMPARISON WITH 4-STROKE DIESEL

ENGINE

The data published in this paper so far is with API’s 4.9 L research

engine that has high friction penalties as seen in the data table in

Appendix A. When the design is optimized for production, API’s 4.9 L

year 2020 engine has been predicted to achieve best BTE of 48.5% and

ESC 12 mode cycle average BTE of 46.6% (180 g/kWh cycle averaged

BSFC) [9] while meeting US 2010 emissions (comparable to BSVI

emissions standards). These data can be compared with 6.7 L Ford

Power-stroke V8 engine [14] and 6.7 L inline 6 Cummins ISB engine

(data published in one report by the International Council of Clean

Transportation (ICCT) [15] and in another by SouthWest Research

Institute (SWRI) [17]). Table 7 below shows comparison of API’s 4.9L

OP engine with Ford Power-stroke and Cummins ISB specications.

Table 7. Specifications of comparable 2-stroke OP and 4-stroke engines

meeting US 2010 emissions standards (comparable to BSVI) .

The SAE paper with Ford Power-stroke [14] and SWRI report [17]

have full steady state BSFC data allowing comparison for steady state

cycles. The SWRI report has also predicted the BSFC of improved

Cummins ISB engine in year 2019 with reduced friction, improved

turbocharger and reduced combustion duration [17]. This data can be

compared with API’s 4.9L production engine for 2020.

Figure 10 show comparison between various medium duty

application engines that meet US 2010 emissions - which are similar

to BSVI emissions standards. As seen from the gure 10, API’s 4.9 L

research engine measured data show 20.7% and 10.7% fuel economy

advantage over 2010 Ford Power-stroke and 2012 Cummins ISB

engines respectively when compared for 12 operating modes of the

ESC cycle excluding idle. With at fuel map for API’s OP engine [8]

[9], higher available torque at lower speeds and improved part load

fuel economy over 4-stroke engines, the vehicle fuel economy

advantage of OP engine in real world driving can be signicantly

Naik et al / SAE Int. J. Engines / Volume 10, Issue 1 (February 2017)

22

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017

higher. When API’s production 4.9L engine predicted performance is

compared with 2019 Cummins ISB predicted by SWRI [17], the OP

engine show 16.2% fuel economy advantage.

Figure 10. 12 mode cycle averaged BTE results comparison shown together

with % improvement with API’s OP engines.

The ICCT has published transient heavy duty FTP data for Cummins

ISB (year 2011) with calibration that allows for slightly higher torque

(1016 Nm) and power (242.5 kW) [15]. The table below show

comparison of measured heavy-duty FTP cycle averaged data on

API’s 4.9L research engine with Cummins ISB MY 2011.

Table 8. Hot start heavy duty FTP cycle results comparison between API’s OP

engine and Cummins ISB.

As seen from table 8, API’s 4.9L OP engine measured data is showing

21.9% fuel economy improvement over Cummins ISB for the

heavy-duty FTP cycle. This is substantially higher than 10.7%

improvement seen from comparing the steady state data in gure 10.

This dataset proves that the at BSFC map of OP engine helps

improve the real world fuel economy almost twice compared to what

can be calculated from steady state BSFC map comparison.

SUMMARY

Opposed piston engines have signicant fuel economy advantage and

potential for lower cost over 4-stroke conventional engines. Achates

Power Inc. has pioneered OP engine technology and shown with

measured data on its 4.9L research engine that -

• API has successfully developed and implemented controls

strategies for the engine to run it effectively on steady state and

transient emission cycles.

• When simulated with Johnson Matthey sized conventional

diesel after-treatment system, API’s OP engine can meet Bharat

Stage VI tailpipe emissions standards.

• API’s current 4.9L research engine is showing 10 to 21% fuel

economy improvement over comparable conventional medium-

duty 4-stroke engine. This fuel economy advantage is expected to

increase with API’s lower friction optimized production engine.

Thus, Opposed Piston engines are capable to address the challenges

faced by Indian OEMs to meet Bharat Stage VI emissions standards

with reduced cost and offer improved fuel economy to the end users.

REFERENCES

1. Heavy-Duty emissions standards for India; Retrieved from Dieselnet

weblink- https://www.dieselnet.com/standards/in/hd.php.

2. Sanchez, F., Bandivadekar, A., German, J., “Estimated Cost of

Emissions Reduction Technologies for Light-Duty Vehicles”, The

International Council on Clean Transportation, 2002. http://www.theicct.

org/sites/default/files/publications/ICCT_LDVcostsreport_2012.pdf

3. Posada, F., Chambliss, S., and Blumberg, K., “Costs of Emissions

Reduction Technologies for Heavy-Duty Vehicles”, The International

Council on Clean Transportation, 2016. http://www.theicct.org/

sites/default/files/publications/ICCT_costs-emission-reduction-tech-

HDV_20160229.pdf

4. Kromer, M., Bockholt, W., Jackson, M., “Assessment of Fuel-Economy

Technologies for Medium - and Heavy-Duty Vehicles”, TIAX LLC.,

Final report to National Academy of Sciences, 2009.

5. Flint, M. and Pirault, J.P., “Opposed Piston Engines: Evolution, Use, and

Future Applications”, SAE International, Warrendale, PA ISBN 978-0-

7680-1800-4, 2009.

6. Warey, A., Gopalakrishnan, V., Potter, M., Mattarelli, E. et al.,

"An Analytical Assessment of the CO

2

Emissions Benefit of Two-

Stroke Diesel Engines," SAE Technical Paper 2016-01-0659, 2016,

doi:10.4271/2016-01-0659.

7. Herold, R., Wahl, M., Regner, G., Lemke, J., and Foster, D.,

“Thermodynamic Benefits of Opposed-Piston Two-Stroke Engines,”

SAE Technical Paper 2011-01-2216, 2011, doi: 10.4271/2011-01-2216.

8. Naik, S., Johnson, D., Fromm, L., Koszewnik, J. et al., "Practical

Applications of Opposed-Piston Engine Technology to Reduce Fuel

Consumption and Emissions," SAE Technical Paper 2013-01-2754.

9. Naik, S., Redon, F., Regner, G., and Koszewnik, J., "Opposed-Piston

2-Stroke Multi-Cylinder Engine Dynamometer Demonstration," SAE

Technical Paper 2015-26-0038, 2015, doi:10.4271/2015-26-0038.

10. Redon, F., Kalebjian, C., Kessler, J., Rakovec, N. et al., "Meeting

Stringent 2025 Emissions and Fuel Efficiency Regulations with an

Opposed-Piston, Light-Duty Diesel Engine," SAE Technical Paper

2014-01-1187, 2014, doi:10.4271/2014-01-1187.

11. Sharma, A., Redon, F., “Multi-Cylinder Opposed-Piston Engine

Results on Transient Test Cycle,” SAE Technical Paper 2016-01-1019,

doi:10.4271/2016-01-1019.

12. Nagar, N., Sharma, A., Redon, F., “Simulation and Analysis of After-

Treatment Systems (ATS) for Opposed-Piston 2 stroke Engine,”

Emissions 2016 Conference.

13. Redon, F., Sharma, A., and Headley, J.,”Multi-Cylinder Opposed Piston

Transient and Exhaust Temperature Management Test Results,” SAE

Technical Paper 2015-01-1251, doi:10.4271/2015-01-1251.

14. DeRaad, S., Fulton, B., Gryglak, A., Hallgren, B., Hudson, A., Ives, D.,

Morgan, P., Styron, J., Waszczenko, E., Cattermole, I., “The New Ford

6.7L V-8 Turbocharged Diesel Engine”, SAE International Technical

Paper 2010-01-1101, 2012.

15. Thiruvengadam, A., Pradhan, S., Thiruvengadam, P., Besch, M., Carder,

D., Delgado, O., “Heavy-Duty Vehicle Diesel Engine Efficiency and

Energy Audit”, http://www.theicct.org/heavy-duty-vehicle-diesel-engine-

efficiency-evaluation-and-energy-audit ,10/12/2014.

16. Heavy-Duty FTP Transient Cycle retrieved from Dieselnet weblink -

https://www.dieselnet.com/standards/cycles/ftp_trans.php

Naik et al / SAE Int. J. Engines / Volume 10, Issue 1 (February 2017)

23

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017

17. Reinhart, T. E., “Commercial medium- and heavy-duty truck fuel

efficiency technology study - Report #2’ (Report No. DOT HS 812 194).

National Highway Traffic Safety Administration. http://www.nhtsa.gov/

Laws-&-Regulations/

CONTACT INFORMATION

Suramya Naik

Chief Engineer and Program Manager

Achates Power, Inc.

naik@achatespower.com

ACKNOWLEDGMENTS

We acknowledge and thank Johnson Matthey for carrying out

after-treatment sizing and simulation activities and for allowing us to

publish the results.

DEFINITIONS/ABBREVIATIONS

API - Achates Power Inc.

OP - Opposed-Piston.

BSFC - Brake Specic Fuel Consumption

BSNOx - Brake Specic Nitrogen Oxides

BSHC - Brake Specic Hydrocarbons

BSCO - Brake Specic Carbon Monoxide

PM - Particulate Matter

THC - Total Hydrocarbon

ESC - European Steady-state Cycle

ETC - European Transient Cycle

WHSC - World Harmonized Steady-state Cycle

WHTC - World Harmonized Transient Cycle

BTE - Brake Thermal Efciency

VTG - Variable Turbine Geometry

ATS - After-treatment System

DOC - Diesel Oxidation Catalyst

DPF - Diesel Particulate Filter

SCR - Selective Catalyst Reduction

ASC - Ammonia Slip Catalyst

CSF - Catalyst Soot Filter

PGM - Platinum Group Metals

CPSI - Cells per square inch

Naik et al / SAE Int. J. Engines / Volume 10, Issue 1 (February 2017)

24

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017

APPENDIX

Appendix A: Measured steady state data on API’s 4.9L OP 2-Stroke research engine

ESC Cycle

Naik et al / SAE Int. J. Engines / Volume 10, Issue 1 (February 2017)

25

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017

WHSC Cycle

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of SAE International.

Positions and opinions advanced in this paper are those of the author(s) and not necessarily those of SAE International. The author is solely responsible for the content of the paper.

Naik et al / SAE Int. J. Engines / Volume 10, Issue 1 (February 2017)

26

Downloaded from SAE International by Suramya Naik, Thursday, July 06, 2017