Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 1

INTERNAL

COMBUSTION

ENGINES

Combined Heat and Power

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 2

Acknowledgments

Principal Authors

Matthew T. Goss, P.E., CEM, CEA, CDSM, LEED® AP (BD+C), CDM Smith

Glynn MacKenzie, P.E. Mechanical Engineer

Jason Wiser, P.E. Brown and Caldwell

Patrick Wootton, Business Development Manager, Nixon Energy Solutions

Myron Bachman, Plant Superintendent, North Davis Sewer District

Final Reviewers

Kevin R Cowan P.E., District Manager, North Davis Sewer District

Tom Phelps, Principal, Stantec

David Wrightsman, PE, Business Development Manager, Energy Systems Group

Water Environment Federation Residuals and Biosolids Committee,

Bioenergy Technology Subcommittee

Dru Whitlock, P.E., Vice President, Environmental Engineer, CDM Smith (Subcommittee Chair)

Jeffrey Layne, P.E., HRSD (Subcommittee Vice Chair)

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 3

Table of Contents

Acknowledgments .............................................................................................................................................................. 2

Table of Contents ................................................................................................................................................................ 3

Executive Summary ............................................................................................................................................................. 4

Combined Heat & Power................................................................................................................................................... 6

Introduction .......................................................................................................................................................................... 6

Fundamentals ....................................................................................................................................................................... 7

Fundamentals & Summary ................................................................................................................................................. 8

Characteristics / Applicability ........................................................................................................................................... 9

Gas Treatment and Appurtenances ............................................................................................................................. 10

Hydrogen Sulfide ................................................................................................................................................................ 10

Siloxanes .............................................................................................................................................................................. 11

Moisture ............................................................................................................................................................................... 13

Fuel Pressurization .............................................................................................................................................................. 13

Fuel Blending ...................................................................................................................................................................... 13

Support Systems & Temperature Control ...................................................................................................................... 15

Heat Recovery ................................................................................................................................................................... 15

Internal Combustion Engine Operations ....................................................................................................................... 17

Case Study 1 ....................................................................................................................................................................... 19

Technical Specifications of Facility ................................................................................................................................ 19

Case Study 2 ....................................................................................................................................................................... 20

Digester Gas Treatment .................................................................................................................................................... 20

Power Generation .............................................................................................................................................................. 20

Heat Recovery .................................................................................................................................................................... 20

Operation and Maintenance .......................................................................................................................................... 21

Special Considerations ..................................................................................................................................................... 21

Gas-Fueled Internal Combustion Engine Criticalities .................................................................................................. 21

Support System Requirements ......................................................................................................................................... 21

Engine Container Solutions .............................................................................................................................................. 22

Rules of Thumb/Considerations ...................................................................................................................................... 22

Additional Resources ........................................................................................................................................................ 24

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 4

Executive Summary

COMBINED HEAT AND POWER

INTERNAL COMBUSTION ENGINE TECHNOLOGY

Reciprocating Internal combustion engine (ICE) technology has been around since the 19

th

century. There

are other types of combined heat and power technologies (CHP) in use at water resource recovery facilities, such

as gas turbines, micro-turbines, and fuel cells. However, as of 2011, 50% of the U.S. water resource recovery

facilities sites with CHP use ICE technology (US EPA Combined Heat & Power Partnership (2011)

Opportunities for Combined Heat and Power at Wastewater Treatment Facilities, Web,

https://www.epa.gov/chp/opportunities-combined-heat-and-power-wastewater-treatment-facilities-market-analysis-and).

CHP is the simultaneous generation of electricity (power), and useful heat (thermal energy) using fuel

energy supplied to the engine-generator ICE technology is an economical option

for

engine-generator

sizes from 200 kW through 2,000 kW, with unit sizes up to 9,000 kW available. There are more than 50 sites

within the US water resource recovery industry demonstrating this reliable technology and

its economic

benefits. In addition, the US Department of Energy (DOE) has been supporting the ARES

(Advanced

Reciprocating Engine Systems) program to develop higher efficiency, lower cost CHP engine

solutions.

ARES has helped produce ICEs with emissions reduced to 0.5

grams/brake horsepower hour of oxides of

nitrogen (NOx), and 2.5 grams/brake horsepower hour of carbon monoxide (CO). These lower emission

limits

allow the ICE technology to meet some of the more stringent emissions required in many jurisdictions.

One of the most important considerations in choosing ICE technology is proper sizing, to match both the

facility’s ‘steady’ electrical load and the available fuel (digester gas). Because ICE CHP systems are

capital-intensive, oversizing the equipment usually results in poor economics due to higher fixed costs and

the associated lower equipment load factor.

Care

also must be used to provide the appropriate fuel treatment system to meet the ICE manufacturer’s

requirements

. Hydrogen sulfide (H

2

S), siloxanes, and water condensation are common digester gas contaminants

which ICEs do not tolerate well, so gas conditioning to remove these is typical to most installations. The degree of

contaminant removal required varies with the digester gas composition and with the specific ICE manufacturer’s

requirements. In some instances, plant owner/operators may decide to reduce or eliminate some gas conditioning

equipment to reduce initial cost, expecting more frequent engine servicing, higher repair costs, and reduced reliability

as a result. However, operating outside the manufacturer’s fuel contaminant limits is likely to adversely affect the

equipment warranty coverage.

Most ICE generators can run on either digester gas, natural gas, or a mixture of the

two. However, it may not be possible to switch between fuels without an engine shut-down, and fuel blending can

be cumbersome. However, because digester gas production rates often vary considerably, providing natural gas as

a supplemental or standby fuel is common. Storage is another way to improve digester gas utilization while better

matching the generator electrical loads.

In addition to

proper fuel treatment ICE generators using primarily digester gas fuel require more

maintenance compared to diesel or natural gas fueled engines. Consequently, engine service contracts

with the engine manufacturer are commonly used. These contracts can cover all routine servicing as

well as major repairs, or routine servicing can be performed by the owner-operator. Remote engine

monitoring is typical and is often required by the manufacturer as a condition of the equipment

warranty.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 5

ICE generators can operate in several different modes to provide electricity to the water treatment facility

and, in some cases, to the electric utility grid. Options include ‘base load’, ‘peak shaving’, and ‘island’

modes, where all generated power is consumed ‘behind the meter’ by the water treatment facility. Island

mode means that the ICE equipment is isolated from the electric utility and serves specific on-site loads. In

island mode, an ICE CHP system can provide emergency power for some portions of the plant. ‘Base

load’ and ‘peak shaving’ are usually most effective when operating in parallel with the electric utility.

However, electric utility interconnection requirements may make parallel operation impractical. In some

cases, the ‘renewable power’ generated can be sold to the electric utility grid at a premium price,

though this is rarely the most cost-effective approach, due to low export prices most electric utilities offer.

Typically, one third of the total energy cost savings from CHP systems is due to the ‘free’ useful heat

produced as a byproduct of power generation, with power cost savings being the remainder. To ensure

that potential heating savings are realized in practice, CHP heat recovery systems and controls must be

closely integrated with the existing plant heating systems. Providing heat to the anaerobic digesters is

usually more important than space heat because the digester heating loads are more continuous

throughout the year and better match generator operating hours.

CHP systems using ICE technology are commonly available in factory-assembled, modular, weather-proof

enclosures. Many manufacturers provide modular CHP systems with unit ratings up to 2,000 kW, and some

provide larger systems. Modular construction simplifies field installation work, and may save on first cost

when no interior space is otherwise available for the equipment. Reduced equipment access for servicing,

especially for major repairs, is one drawback. For example, if you have to remove the engine from the

container to change the heads it can prove to be a costly O&M challenge. Some containers offer fully

removable sides solving this problem.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 6

Combined Heat & Power

Introduction

This document provides a status review of combined heat & power (CHP) technologies applicable for

implementation at water resource recovery facilities. Combined Heat & Power (CHP), also called

‘cogeneration’, is defined as the concurrent or simultaneous production of electricity and thermal energy

from a power generating device. Reciprocating Internal Combustion Engines (ICE) provide nearly 2.3 GW

of power capacity in CHP installations. This report describes the technology, theory, and operation of such

facilities, as well as providing technical data from available manufacturers.

The original ICE was created in 1859 as a means of converting chemical energy (fuel), typically in the form

of gasoline or diesel, into mechanical energy. As the fuel is burned in the combustion chamber in the

presence of high pressure air, a controlled explosion results in a force that drives the piston (or in the case of

a gas turbine, the turbine blades) creating mechanical energy.

Technological improvements have increased the ICE’s efficiency, largely by decreasing frictional losses in

moving parts and improving the precision timing in the combustion process, where the air/fuel mixture is

drawn into the chamber before being compressed, ignited, and exhausted (Figure 1). In addition, ICEs

remain a common power source in the 21st century because of their adaptability, whether in the form of a

reciprocating piston engine for automobiles and ships, or stationary applications in power plants where the

engine’s mechanical energy is converted to electrical energy through a generator.

Figure 1: The Four Stages of Combustion in a Four Stroke Reciprocating Engine

(Source: Urone, Paul Peter, and Roger Hinrichs. "College Physics." Chapter 15, Thermodynamics, p. 587;

OpenStax. Creative Commons Attribution License V4.0, 21 June 2012. Web. 06 July 2017.)

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 7

Fundamentals

Although the majority of ICE’s are used for transportation purposes in motor vehicles, this document is

focused on stationary engine/generator applications for power production. Internal combustion engines

and heat recovery methods are the cornerstones of Combined Heat and Power systems at all scales. For

universities, hospitals, data centers, and municipal utilities, ICE technology is the most common way to

provide standby power should the electric utility fail. At some sites, adding heat recovery to create a CHP

system allows the facility to provide its own power more economically that purchasing power from the grid.

The combustion process for reciprocating engines can vary widely stemming from the various manufactures

trying to match their engines to the specific needs of various customers. Applications like lawnmowers and

outboard motors require less precision and reliability, and many of those use simpler two-stroke engines.

Reciprocating engines with high power to weight ratios were preferred for use on World War II era aircraft

before being replaced by jet engines and turboprops in 1944. The higher electrical efficiency of these

reciprocating engine-generators, as well as their operational flexibility in ramping up and down for load

matching, led to their use in over 2,000 CHP facilities throughout the United States.

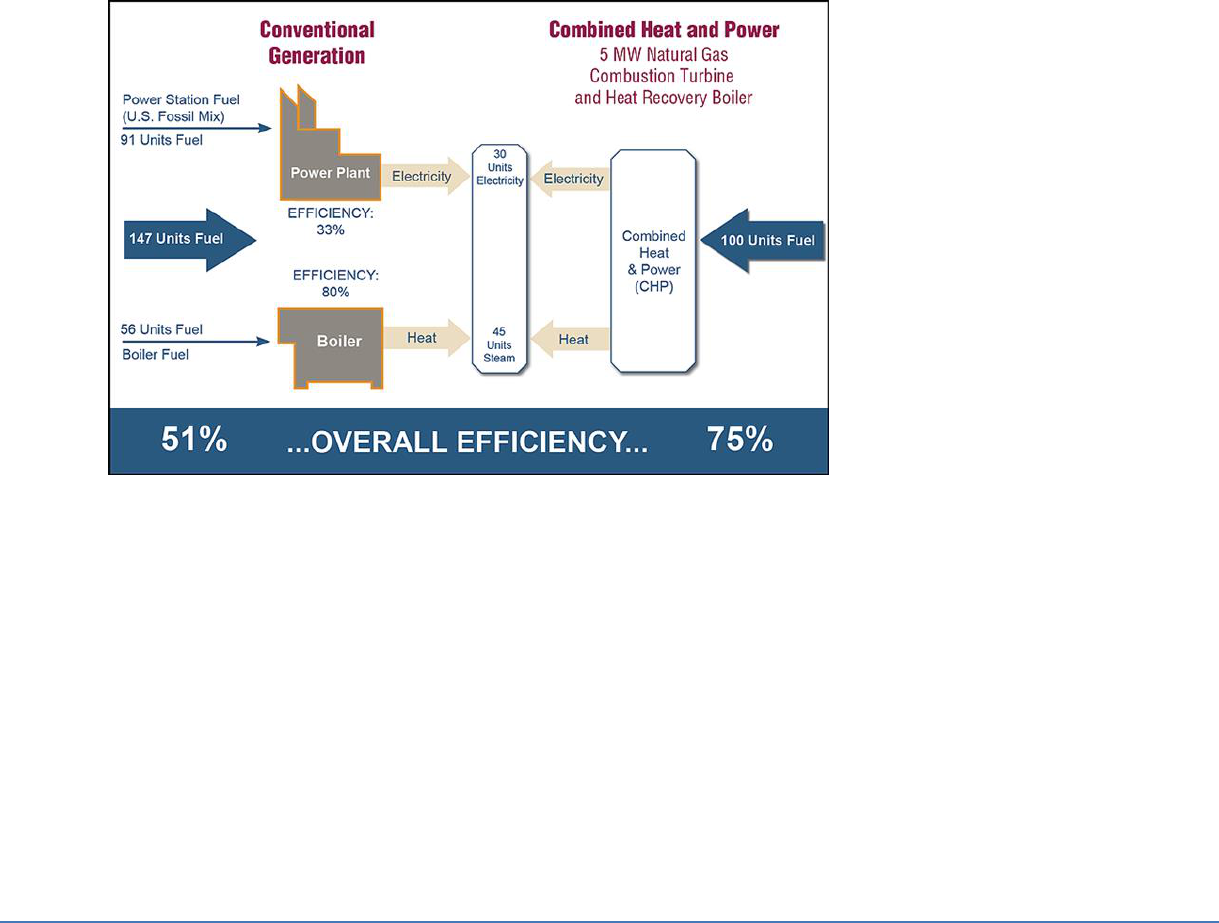

Figure 2: CHP vs. Conventional Generation

(Source: USEPA, Combined Heat and Power Partnership (2015) "Fuel and Carbon Dioxide Emissions Savings Calculation Methodology

for Combined Heat and Power Systems," Feb. 2015, p. 5. Web., https://www.epa.gov/sites/production/files/2015-

07/documents/fuel_and_carbon_dioxide_emissions_savings_calculation_methodology_for_combined_heat_and_power_systems.pdf)

The central theme of CHP applications is converting chemical energy from fuel into both electrical and

thermal energy. Shown in Figure 2, this simultaneous production of energy in two forms typically increases

overall efficiency from 45 percent to around 70 percent or more. Of paramount importance, however, is

matching the CHP capacity to the facility simultaneous thermal and electrical demand, because

recovered heat energy can only improve the efficiency if it is properly utilized. For example, a facility with

constant electrical and thermal demands of one megawatt electrical demand and three million BTU/hr

heat demand respectively, would be a great fit for CHP. However, should the one megawatt electrical and

three million BTU/hr heat load not coincide, the facility will lose the benefit of simultaneous production.

Therefore, load matching and its seasonal fluctuations play a large role in assessing the ‘real world’

economic viability of a CHP plant.

The potential for efficiency improvements has received a renewed focus in recent years, as a result of rising

costs of energy, environmental concerns over reducing fossil fuel use, and emissions impacts. CHP presents

an economical existing technology to meet the country's rising energy demands without fundamentally

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 8

changing the infrastructure. This renewed focus is driving the US Department of Energy's effort to provide 20

percent of all electric generation through CHP by 2030, up from 8% in 1978 (U.S. Department of Energy,

Powering Progress in Combined Heat and Power (CHP) (2008) Web.,

https://www1.eere.energy.gov/manufacturing/distributedenergy/pdfs/itp_chp.pdf).

Fundamentals & Summary

While all reciprocating internal combustion engines units use the same basic operating principles, there are

various technology differentiators. Specifically, for “spark ignition” reciprocating internal combustion

engines, there are:

High Speed

(1000-3600 rpm)

Medium Speed

(275-1000 rpm)

Rich Burn

0.01 – 1.5 MW

Lean Burn

0.15 – 3.0 MW

1.0 – 18 MW

Source: Data from U.S. EPA

Technological improvements since the development of the first ICEs have enhanced the

combustion

control systems, resulting in increased efficiencies and reduced emissions. While rich

burn engines operate

at a near stoichiometric air to fuel ratio (AFR), lean burn engines essentially

flood the combustion chamber

with air, nearly doubling the amount of air for fuel combustion. The

more diluted mixture reduces peak

combustion temperatures, reducing oxides of nitrogen (NOx)

emissions which are primary contributors to the formation of

ozone and other health problems. The

lean burn engine's lower NOx levels, at five to ten percent of the rich burn

engine's, provide the

highest possible efficiency level for moderate emissions limits of 250-500 mg/Nm

3

NOx

(at 5 percent

O

2

in the exhaust gas).

However, when more stringent emissions limits are required, as in most of the Northeast United States,

both

lean burn engines and rich burn engines require exhaust gas treatment through a catalyst. The

rich burn

engine's near stoichiometric exhaust gas composition and high combustion temperatures

allow the use of a

simple three way catalyst, similar to those utilized in automobile exhaust systems, to

reduce NOx, Carbon

Monoxide, hydrocarbons, and other harmful air pollutants. Unfortunately, the

simple three-way catalyst

used in rich burn engines requires clean fuels like natural gas. Biogas,

digester gas, and landfill gases cannot

be used due to their potential for "poisoning" the catalyst.

The lean burn engine, on the other hand, requires selective catalytic converters with Urea

(Ammonia) injection, which adds expense and other

toxicity and exposure concerns when stored in

large quantities on site.

The US Department of Energy (DOE) has been supporting the ARES (Advanced Reciprocating

Engine

Systems) program to develop higher efficiency, lower cost CHP engine solutions. Through this

program engine efficiency (without heat recovery) has been increased to as high as 43.5%.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 9

Characteristics / Applicability

When considering the potential for employing gas-fueled reciprocating engines to operate on

digester gas, there

are a significant number of available manufacturers of reliable equipment.

The process of combusting digester gas for the

purposes of combined heat and power (CHP) has

been executed successfully at a large number of

facilities both globally and within the United

States. Numerous manufacturers of gas reciprocating engines

have demonstrated product

competence in this arena. This section of the paper discusses these proven

manufacturers, engine

performance, and emission performance as they apply to operations on digester gas.

Several years ago, the gas reciprocating engine market experienced a consolidation in

competing brands

offered. General Electric (GE), the owner of Jenbacher gas engines,

purchased Waukesha gas engines,

and Caterpillar, at about the same time, purchased the

MWM gas engine brand. While Cummins also

offered high quality engines. This market

consolidation may have seemed to reduce the competitive

nature and technological

advancement of the engine market, but the acquired brands are still offered in the market

through their new parent companies. All three gas engine

manufacturers, Caterpillar, Cummins,

and GE have continued to invest in their product offerings. Additionally, reputable European gas

reciprocating engine manufacturers such as MTU, Siemens (who acquired Dresser and Guascor)

Liebherr, and MAN have entered the US market for digester gas applications.

When evaluating the potential for generating electrical energy from digester gas, the first

consideration for

the project owner is to match the size of the reciprocating engine to the process

flows and electrical loads. Gas reciprocating engines

range in size from 140 kW

el

to over 9,000

kW

el

. A rough rule of thumb is that a 10-MGD average flow plant would

produce enough

digester gas to power 330 kW

el

, while a 25-30 MGD average flow plant would produce

enough

gas to generate up to about 1,000 kW

el

. It is a rare occasion that a digester gas facility would not

be able to find an ICE generator size that could efficiently accommodate its gas production rate.

Performance of gas engines is based upon the efficiency of the engine in converting chemical

energy from

the digester gas to electricity and heat. Gas reciprocating engines consist of an

alternator (electrical power generator) and an engine

component. The engine component

combusts the digester gas thereby producing mechanical energy. This mechanical energy is then

converted to electricity by the alternator. Heat is recovered from the engine component as a

byproduct of power generation. In the recent past significant improvements in power generation

efficiency have been achieved by most of the ICE manufacturers. Programs, such as the

Advanced Reciprocating Engine System (ARES) funded by the United States Department of

Energy, have

supported these technological advancements. In the case of the ARES program

specifically, it produced

improvements to American manufactured gas engines and responses in

kind from European and other

manufacturers. Overall engine performance is rated on electrical

efficiency, thermal efficiency, and

overall combined efficiency (a summation of thermal and

electrical efficiency). A typical range of fuel-to-electrical power efficiencies is from 35% to 45%

based upon the Lower Heating Value (LHV) of the digester gas. Thermal efficiency is a measure of

the heat recovered from the engine during combustion compared to

the energy input of the

digester gas. Typical thermal efficiencies range from 40% to 50%. As a rule of

thumb, gas

reciprocating engine’s heat is recovered from the engine lube oil, engine jacket water, engine

intercooler, and exhaust. Approximately half of the heat is high temperature heat (700

o

F – 950

o

F)

recovered from the exhaust with the remainder recovered from the lower grade temperature

elements

made up by the combined lube oil, jacket water, and intercooler, (180

o

F – 230

o

F).

Finally, the total

efficiency of a CHP system is the summation of the electrical and thermal

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 10

efficiencies of the engine. Total

engine efficiency ranges from 75% to 90%. The more electrically

efficient engines have lower thermal

performance whereas higher thermally performing engines

have a lower electrical efficiency.

The future for digester gas-fueled CHP projects using gas reciprocating engines will likely see

greater

importance placed on engine emissions. Currently, the two most significant emissions in

terms of air

permitting are NO

x

and CO. Either of these emissions, or both, can be limiting factors

when permitting gas

engines. It is common for engine manufacturers to set their engine emissions

performance based upon NOx output. The most efficient engines will emit NOx in a range of 0.5 –

0.6 g NOx/bhp-hr. In locations

where less stringent NO

x

standards exist, manufacturers provide a

1.0 – 1.1 g NO

x

/bhp-hr. The typical range

for CO emissions is 2.5 - 3.0 g CO/bhp-hr. Additional

emissions performance requirements such as

formaldehydes, VOC, and SO

x,

may also be

included in the air quality permit in certain locations. Engine

emission ratings for all parameters

often depend upon the condition and relative cleanliness of the digester

gas.

Gas Treatment and Appurtenances

Digester gas contains impurities that can shorten the life and degrade performance of all types of

CHP

prime movers, including internal combustion engines. Therefore, fuel pretreatment is required

for nearly all

digester-gas-fueled CHP applications. Hydrogen sulfide (H

2

S), liquid moisture, and

siloxanes are of particular concern and

should be controlled to meet the CHP system’s prime

mover fuel specifications.

Hydrogen Sulfide

Hydrogen sulfide, (H

2

S), is oxidized during combustion leading to the formation of acidic sulfur

dioxide, (SO

2

)

which can be extremely corrosive to internal combustion engine components. High

H

2

S concentrations in

digester gas can turn engine and compressor oil acidic, resulting in more

frequent oil changes and

increased maintenance. Unless removed from digester gas fuel, H

2

S

can lead to equipment corrosion,

increased maintenance and associated maintenance costs,

and a shorter equipment lifespan. Most ICE manufacturers limit H2S in the fuel to 100 ppm, but H2S

levels in digester gas are frequently 1,000 ppm or more. There many techniques commercially

available for H2S removal, and many are proprietary. In this section, we touch on only a few of

these removal techniques.

The presence of H

2

S in digester gas adversely affects the quality of combustion emissions. As

stated above,

the combustion of H

2

S produces sulfur dioxide (SO

2

), which is the most common

source of SOx (oxides of

sulfur). Therefore, the removal of H

2

S and other sulfur species from the

digester gas fuel causes an

equivalent reduction in SOx emissions. This is an important air

permitting consideration because air permits

often limit SOx.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 11

Iron sponge treatment is commonly used at WRRFs to remove H

2

S from digester gas. In this

process, the

saturated digester gas flows through process vessels containing wood chips

impregnated with hydrated

ferric oxide (Fe

2

O

3

· H

2

O). The H

2

S reacts with the ferric oxide to

form iron sulfide (Fe

2

S

3

) according to the

following equation:

Fe

2

O

3

· H

2

O + 3H

2

S Fe

2

S

3

+ 4H

2

O

This process requires the digester gas to be saturated with water vapor and is therefore typically

the first

step in the fuel treatment process, before moisture is removed. Certain iron sponge

systems are capable of

media regeneration. The addition of oxygen and water to the iron sulfide,

in the absence of digester gas,

produces hydrated ferric oxide and elemental sulfur, and thus

partially regenerates the iron sponge media.

Eventually the iron sponge media will become

exhausted and regeneration is no longer an option. Once

exhausted, the nonhazardous, iron

sulfide laden, wood chips can be safely disposed of at most municipal

landfills.

Media removal and replacement is maintenance intensive. Also, iron sponge media has been

known to

smolder when exposed to oxygen or even spontaneously combust. Therefore, the

operation of an iron

sponge system requires careful process control. Access to the vessel can be

difficult, especially if inside a building; therefore, careful consideration of media change out is

essential.

Other H

2

S removal alternatives feature proprietary iron oxide sorbents. These systems include

SULFATREAT

®

,

Sulfur-Rite®, and SULFA-BIND®, all of which feature an inorganic substrate to which

the proprietary sorbent adheres. Like the iron sponge, these alternative media can typically be

regenerated and once exhausted

can be safely disposed of at most landfills. Also like the iron

sponge, these alternative media often perform

best with water-saturated digester gas.

Biological reactors are sometimes used in larger applications. These consist of an enclosed tower

where digester gas passes upward through a wetted packed tower containing microbes which

capture H2S and convert it to elemental sulfur, which is removed by periodic washing. The

advantage is that there is no absorbent or media requiring regular replacement. One drawback is

that the microbe colonies thrive best in a stable environment, which is not always easy to maintain

or re-establish after a shut-down for maintenance.

Siloxanes

In recent years siloxanes have become a growing problem for digester-gas-fueled CHP systems.

Siloxanes

are silicon-based, man-made, volatile compounds that make their way into domestic

wastewater via

personal care products such as soaps, shampoos, sunscreen, lotions and

deodorant. Siloxanes are also

prevalent in dry cleaning agents, paper coatings, and textiles, all of

which may reach WRRFs as a result of

industrial discharges. The word “siloxane” is derived from:

silicon, oxygen, and

alkane. In actuality, siloxanes are large organic molecules consisting of a

silicon atom, to which an oxygen

atom and two hydrocarbon groups are attached. During the

wastewater treatment process siloxanes

become entrained in sewage sludge and are

subsequently released into digester gas during the digestion

process. Siloxanes are gases that are

released from solution in proportion to their vapor pressure and thus in

direct proportion to the

sludge temperature. This is the reason digester gas produced under thermophilic

conditions has

higher levels of siloxanes than digester gas produced by mesophilic digesters. While siloxane

concentrations are generally very low, typically only a few parts per million or less, their presence in

digester

gas can have debilitating effects on combustion equipment and CHP system

components. If not removed

from digester gas to appropriate levels, siloxanes may manifest

themselves as hard, abrasive deposits on

combustion components. Siloxane deposits have been

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 12

known to clog engine heads and fuel injectors, foul

exhaust intake valves, and coat combustors,

and turbochargers. These deposits are often friable, but are abrasive when introduced into

moving parts.

One of the more common approaches to siloxane removal at WRRFs is adsorption with an

activated

carbon media. With this approach digester gas flows through vessels containing the

activated carbon

media, which adsorbs siloxanes and other large molecular contaminants.

Upstream removal of H

2

S and

water is important to achieving optimal siloxane removal. If not

removed, H

2

S and water can limit the

effectiveness of the activated carbon. In contrast to iron

sponge, activated carbon performs best with

drier digester gas. Therefore, activated carbon

vessels should be placed downstream of moisture removal

equipment. Digester gas temperature

also influences activated carbon performance.

In recent years several siloxane removal systems with on-site media regeneration capabilities have

been

marketed. Some of these systems employ activated carbon for siloxane removal while others

use a

proprietary blend of silica gel-based media. Most media regeneration systems are based on

a temperature

swing adsorption (TSA) process. TSA systems adsorb siloxanes at low temperatures

and desorb the captured

siloxanes at high temperatures. Captured siloxanes are removed from

the system by passing small amounts

of hot air over the siloxane laden media. Recovered siloxanes

are eliminated by combusting the

regeneration air in a dedicated flare. These proprietary systems

are continually evolving and improving and seem to have potential as a viable alternative to

traditional activated carbon.

In the case of adsorbing media based systems, siloxane breakthrough can be detected by frequent

digester gas sampling and laboratory analysis. The drawback to this approach is that it can be

prohibitively

expensive. In the case of internal combustion engines, siloxane breakthrough can be

detected by regular

lube oil sampling and analysis. The drawback of this approach is that siloxane

breakthrough cannot be

definitively determined until after the contaminated fuel has passed

through the prime mover. Many WRRFs

change out adsorbing media by predicting siloxane

breakthrough based on past operating experience. In

these cases, adsorbing media is usually

changed out at regularly scheduled time intervals or after a certain

volume of digester gas has

been treated. Often siloxane removal media change outs occur during regularly scheduled

maintenance on the prime mover to minimize the downtime of the overall CHP system. Pressure

swing adsorption (PSA) systems are similar in concept to TSA systems. In the case of PSA systems

siloxanes are adsorbed at high pressures and desorbed at low pressures. One of the drawbacks of

the

regeneration process is that usually up to 10 percent of the digester gas methane is lost in the

process. With

the proper media and pressures, PSA systems can be configured to selectively

capture and remove other

digester gas contaminants such as CO

2

and H

2

S. Other less frequently

used options for siloxane removal

from digester gas include refrigeration and deep refrigeration.

Refrigeration systems are characterized by chilling the digester gas down to about 40 degrees

Fahrenheit. This process is thought to dissolve siloxanes

into the condensate stream, as opposed to

the siloxane compounds condensing out of the gas. In contrast, deep refrigeration, or cryogenic

refrigeration, processes cool the digester gas to below freezing

temperatures. Alternating the flow

of digester gas between refrigerant and gas heat exchangers prevents

the system from freezing.

Siloxane removal occurs as a consequence of the condensed water. Reheating

of the purified

and cold digester gas is required prior to combustion. Reheating the cold digester can

usually be

accomplished as a consequence of compressing the gas, which is often necessary to

compensate

for pressure losses in downstream treatment systems and to meet fuel pressure requirements at

the

prime mover.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 13

Moisture

Digester gas is fully saturated with water as it is produced within anaerobic digesters. A

consequence of

saturation is that liquid water will condense out of the digester gas with any

reduction in gas temperature. If

not properly controlled, the presence of condensate can restrict

digester gas flow through piping and

treatment equipment, limit effectiveness of siloxane treatment

media, and cause corrosion due to the

presence of H

2

S. Liquid water introduced into a

reciprocating engine can also cause mechanical problems, particularly by dislodging siloxane

deposits which may be present. Certain digester gas treatment processes and some types of

digester gas treatment

equipment function best when the digester gas is dry. Moisture can be easily

removed from digester gas by

cooling the gas below its dew point and condensing the liquid water

out of the gas. Mechanical gas dryers

or heat exchangers coupled with water chillers are

commonly used for this purpose. Desiccant driers and

coalescing filters can also be used for

moisture removal. Desiccant dryers can produce exceptionally dry

gas but must be regenerated,

while coalescing filters can only remove liquid water droplets.

Fuel Pressurization

Most anaerobic digesters operate at a pressure from 4 to 18 inches WC. These low pressures must

be

increased in order to convey gas to the prime mover while overcoming pressure losses through

the

conveyance and treatment system. Most lean burn

internal combustion engines require

digester gas fuel to be delivered at 2 to 6 psig. Certain lean burn

engines include a pre-chamber,

which requires a small amount of the digester gas fuel to be pressurized up

to 80 psig.

Placement of digester gas pressurization equipment within the overall fuel treatment process is an

important

consideration. When possible, it is good engineering practice to locate digester gas

pressurization

equipment downstream of the H

2

S and moisture removal processes to ensure that it

handles only dry, acid-

free gas. Another advantage of this design approach is that the heat of

compression increases the gas

temperature above the dew point thus limiting further

condensation from occurring in downstream piping

and processes. Pressure losses caused by

digester gas treatment processes, equipment, and piping is

another important consideration when

locating pressurization equipment and should be minimized

wherever possible.

Fuel Blending

Fuel blending is another viable tool for increasing the operational benefits of ICE technology. Fuel

blending is the addition of natural gas and/or natural gas and air to maintain a constant and

consistent quantity and

quality of fuel. The first blending is the addition of natural gas only to

provide a consistent quantity of fuel to

the engine. This can greatly increase the methane content

of the fuel and may also be used to sweeten

the methane content of the fuel in times of plant

digester gas upsets. When using this option controls must

be provided to measure and transmit the

heat value of the fuel to the engine controls, or provide a way

that the engine fuel controls can

not only measure the heat value to meet required emission limits, but also

to protect the engine

from detonation. The second mode is blending natural gas with air to match the heat

value of the

facilities digester gas. This mode removes the requirement of an online methane analyzer or

more

sophisticated engine fuel controls and has over 20 years of reliable operation in multiple facilities.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 14

Figure 3 depicts a fairly common digester gas fuel conditioning schematic used for CHP systems

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 15

Support Systems & Temperature Control

Often overlooked in considering ICE cogeneration systems are the support systems that are required for a

successful installation, which include mechanical systems for engine cooling and ventilation, exhaust

treatment systems, and fuel treatment systems. In addition, upgrades to the electrical, structural, and noise

attenuation systems should also be expected.

Proper engine temperature control is essential to ensure consistent and efficient operation of ICE engines. It

is for this reason that “heat recovery” systems should be carefully designed and integrated with CHP

equipment, support systems, and the structures where it will be located. Regardless of what heat recovery

needs may exist within the overall CHP system, the engine itself must be provided a continuous,

dependable source of cooling water with proper temperature, pressure, and quality. Because of this

requirement, CHP installations must include a “heat dump” (radiators, heat exchangers, etc.) and control

valves to ensure consistent engine operating temperatures are maintained. A decoupling heat exchanger

is often used to separate the engine’s “cooling” water loop from the facilities “heating” water loop.

Sometimes treated effluent water is used for rejecting excess heat, but this introduces problems with heat

exchanger fouling, which can affect CHP system reliability.

Control of the engine cooling system can be relatively simple: cool the engine with relatively cold water

available from the facility, and harness the heat of combustion in the cooling loop and exhaust for heating

anaerobic digesters, building space, or other needs which also acts as the systems heat dump. If the need

for heat is not adequate to provide sufficient cooling of the cooling loop, which often occurs during periods

of reduced heating demands in the summer, the controls shall energize the heat dump radiators or heat

exchangers, and reject the heat to the atmosphere or waste cooling loop, therefore maintaining engine

temperature. However, this results in a reduction in recovered thermal energy, and decreases the total

system efficiency, which then more closely resembles conventional generation without heat recovery.

Temperature control of the engine’s intake air is also critical to maintain the engine’s higher efficiency, and

maintain the lower emission requirements. Since the intake air temperature window width is relatively

narrow, around 20°F, a facility may need to provide both cooling and heating of the intake air, depending

on the regions temperature swings during different seasons.

Heat Recovery

As discussed previously, an essential principle of CHP systems is "load matching," wherein the CHP's energy

production is sized to fit the energy demands of the facility it supplies energy to. While the electricity is

always fed to the system through the engine's generator, the thermal energy available from the CHP Heat

Recovery System often comes in a couple of forms that can be used for different purposes. These forms are

classified as "Low Grade Heat" or "High Grade Heat."

Low grade heat refers to heat recovery at lower temperatures, generally at or below 200 degrees F, which

can provide hot water or hot glycol to facility processes. With temperatures below the saturation

temperature where water vaporizes, low grade heat cannot be used for steam production. Typical ICE’s

provide low grade heat, which can account for nearly half of the thermal energy available from CHP. This

low-grade heat comes from the engines jacket water, turbochargers, and lube oil coolers.

High grade heat is recovered from higher temperature sources, reaching up to 1,000 degrees F, and, it may

be used for generating hot water, or for generating steam. This steam may be used for building heating, but

with recent wastewater treatment developments in thermal hydrolysis, it may be better to utilize high

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 16

pressure steam from CHP equipment to further break down the organic products at the digester and

generate more digester gas for use at the facility. However, bear in mind producing higher pressure steam

means that less exhaust heat is recoverable.

Exhaust gas heat recovery is the most common form of high grade heat derived from CHP engines. The

exhaust gas heat accounts for the other half of thermal energy available from CHP. However, a

reciprocating engine has reduced levels of high grade heat recovery when compared to other CHP

technologies such as gas turbines, which are less electrically efficient but provide recovered heat as high-

grade heat. The heat recovery system must be tailored specifically for the application, with the load

matching in both quantity and form to be fully utilized.

Figure 4 depicts a fairly common digester gas fuel conditioning schematic used for CHP systems

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 17

Internal Combustion Engine Operations

Internal combustion engine facility operations can be broken down into three primary modes of operation:

Peak Shaving, Base Loading, and Island.

Peak Shaving Mode: Running engines to reduce utility electrical demand during facility peak electrical

usage period is ‘peak shaving’. Most electrical utilities charge a premium for on-peak power demands,

during specified time periods during weekdays, usually from 7:00am until 11:00pm. Off-peak usually has

lower demand and kilowatt-hour charges. Usually, a set utility KW limit is programmed and the engines will

ramp up or down to maintain this value. If a facility has multiple engines, additional options are available.

Base Load Mode: This involves setting the engine at a fixed load, usually at about 75% to 100% output, to

maximize efficiency, or to match and utilize all digester gas being produced. Most internal combustion

engines have a narrow turn down range and to maintain efficiency they must stay within that range. Turn

down ratio refers to the minimum to maximum range over which the engine can meet both its published

emissions and efficiency.

Island Mode: This means powering the facility by the engines while operating independently from the utility.

Facilities may wish to use this mode during times of high utility demands or during times when high demands

during the summer season, or when the utility is unstable or unreliable. Some utilities may offer a very

attractive incentive to larger facilities that have the ability to drop off the grid during high utility demands.

One factor that may affect how engines are operated is the quantity of digester gas a facility produces

over a 24-hour period. Some facilities may have a way of storing gas which may allow them to utilize more

engines or run at higher loads during peak hours. Other facilities may have the ability to blend natural gas

to subsidize digester gas. In this case the cost of natural gas will enter into the decision-making process. The

cost of utility power also plays a large role in these decisions. Another factor influencing how the system is

best operated would be the ability to implement co-digestion thereby increasing the quantity of digester

gas available.

For the plant operators, operation of an internal combustion engine CHP system can be very challenging,

but also can be simplified through training and operator buy-in to the system and the increased value it

brings to their facility. Generally, all that is required to simplify operations and maintenance of a CHP system

is a simple check sheet to guide the operators through what is necessary to inspect during one of their

regular rounds, very similar to checking any other piece of plant equipment. This type of inspection should

be conducted daily. Things such as checking oil level, draining fuel system condensate traps, checking for

both coolant and oil leaks, unusual noises, belts and other predetermined gauges is all that is required of

the operators. Offsite electronic monitoring may be available and might be a good option for some smaller

facilities. Verifying functionality of all support equipment is also very important and usually the role of the

operator. Systems such as HVAC, fuel system, and cooling systems may require visual inspection and

occasional testing of current conditions. Facilities who have succeeded in operating a CHP have usually

invested heavily into the training of their operational staff.

Operations and maintenance of an internal combustion engine CHP system requires a very large

commitment. Maintenance can be broken down into several categories, routine, quarterly, annual, and

scheduled.

• Routine maintenance includes things such as oil sampling, oil changes, spark plug replacement, oil

and air filter replacement, cooling system testing, battery maintenance and etc. All of these services

can very easily be performed by the facilities maintenance staff with very minor training. This is

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 18

usually performed every 750 to 1500 hours of engine operation depending on level of gas treatment

and oil sampling results.

• Quarterly inspections include valve adjustment, monitoring valve recession, and depending on air

quality requirements, emission monitoring to verify compliance. Quarterly inspections may also

include bore scoping cylinders, but this level of service requires a larger level of technical skill.

• Annual inspections may include block alignment, bearing inspections, engine protective shutdown

verification, and general overall performance review.

• Other scheduled maintenance could include top end overhaul, cylinder inspection, complete

engine overhaul, and should only be completed by a trained mechanic for that engine type.

Facilities may desire to contract out all maintenance of their CHP engine, or, depending on their staff skill

level, maintenance abilities, and circumstances they may choose to perform some or all of the

maintenance in-house. Due to modern engine technologies and the required maintenance of these

technologies, more specialized technician skills, smaller facilities may benefit more by outsourcing all or

most of their maintenance. Facilities with a larger maintenance staff may choose to complete most

maintenance tasks in-house. Factors to consider when making this decision include closeness of the facility

to an authorized repair facility, ability of the service technicians, response time, the facility’s back-up, and

process vulnerability, and costs if the system is down for an extended period of time. In any case the

maintenance of the internal combustion engine CHP is the largest contributor to the success of its overall

reliability.

Regardless of the facility’s decision to complete maintenance in-house or outsource, there is still a large

amount of training recommended for all staff members on the CHP unit and its support equipment. Heat

exchangers, oil make-up system, fuel treatment systems, and air quality monitoring, are all standard

operating requirements that will require training and general review of standard operating procedures,

especially if these types of services are not completed routinely. It may be required for air quality emission

inventories to be reported every other year, but a staff member will have to know how to complete

emission inventory reports.

One of the largest factors influencing a facility’s decision on whether to outsource their maintenance or not

is their ability to obtain local product support. Does the local vendor have a competent service and parts

staff? Do they have a long-term commitment to the facility? Do they stock sufficient parts to cover the most

common failures? Qualifying the support is an important component of selection. Careful evaluation of the

part stocked versus ordered, distance technicians must travel, response time, and references all must be

evaluated as much as the cost of service.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 19

Case Study 1

The North Davis Sewer District in Syracuse, Utah installed their first cogeneration facility in 1972. The system

consisted of two 250 kW Caterpillar powered generators, heat was only recovered from the engine

coolant, and used to heat their 1 million gallon anaerobic digester. The installation also included two

digester gas fired boilers. The fuel supply system consisted of floating gas storage digester lids, a Nash liquid

ring compressor, and a four-inch flare. Generator controls allowed for operation on total generator power,

split power between utility and generator on isolated busses, or total utility power.

In the 1980’s, two new 1 million gallon primary digesters were constructed, two Waukesha 513 kW dual fuel

rich burn engines were installed and replaced the Caterpillar generators along with the outdated boilers.

The system had full heat recovery. In 1999, a completely new fuel train was installed as well as a 923 kW

Waukesha lean burn engine. The gas train consisted of new stainless steel piping, safety controls, low

horsepower multistage digester gas blowers, a gas mixing system that blended natural gas and air, to

maintain 600 BTU’s, that maintained a constant digester lid pressure, and a 6” candlestick flare. In 2004, the

facility completed an electrical upgrade that included the addition of a 2 megawatt Caterpillar diesel

powered emergency standby generator along with paralleling controls that allow paralleling all engines to

the utility and to each other, thereby providing excellent reliability and flexibility.

Technical Specifications of Facility

• Treatment Facility Location: Syracuse Utah

• Treatment Facility: 34 MGD Trickling Filter / Solids Contact Hybrid Plant

• Digester Capacity: 4-1Million Gallon Primary Digesters

• Power Generation Ability: 1,950 kW Digester/Natural Gas, 2,000 kW Diesel Back-up

• Heat Recovery Per Engine at Full Load: 2.4 Million BTU’s/Hour

• Digester Gas Produced: 320,000 Ft

3

/Day

• Treatment Facility power Demand: Winter 1,000 kW, Summer 1300 kW

• Treatment Facility Demand Costs: Winter $16.00/ kW, Summer $20.00/ kW

• Treatment Facility Energy Costs: Winter $.040/ kWh, Summer $.05/ kWh

• Annual Cogeneration Operational Maintenance Costs: $85,000.00

• Annual Cogeneration Maintenance Labor Costs: $50,000.00

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 20

Case Study 2

The Point Loma Wastewater Treatment Plant (WWTP) San Diego, California provides primary treatment for

approximately 160 million gallons of domestic sewage sludge per day. As part of the overall treatment

process, the plant operates an anaerobic digestion system, which includes 8 digesters. The anaerobic

digesters produce approximately 3 million cubic feet of digester gas per day. Installed in 1999, the CHP

system at the Point Loma WWTP consists of two Caterpillar 3612 internal combustion engines. Each engine

has an electrical generation capacity of 2,300 kW. The engines operate at about 36% electrical efficiency

and together are capable of producing up to about 4.6 MW of electrical power. At full output, the

engines convert about 1.8 million cubic feet per day of digester gas to energy. Strict air regulations in

southern California prevent the Point Loma WWTP from installing additional cogeneration engines. Plans

are underway to transport and use the excess digester gas offsite. In the interim, the current practice of

dealing with the excess digester gas to burn it in onsite flares.

Digester Gas Treatment

The Point Loma CHP system includes a gas treatment system that converts the raw digester gas into a

suitable fuel for the cogeneration engines. The treatment system consists primarily of particulate and

moisture removal equipment and compressors. The digester gas treatment and handling system provides

the engines with 50 psig fuel that is of adequate quality for combustion and conversion to useful energy.

Normal operation of the Point Loma WWTP includes the addition of iron salts to the plant’s influent flow

and also to the solids feed to the anaerobic digesters. The addition of iron salts to the plant process

limits the concentration of hydrogen sulfide in the digester gas to acceptable levels specified by the

engine manufacturer.

Power Generation

The engine installation and the digester gas treatment system include several items of ancillary equipment

which impact the overall net electrical efficiency of the CHP system. Parasitic loads observed at the Point

Loma WWTP were evaluated on a per engine basis and include gas compressors, gas chillers, chiller

pumps, effluent cooling pumps, and engine auxiliary systems. The total parasitic load attributable to each

engine was about 330 kW. Thus, the net power production observed at the Point Loma WWTP was nearly

4 MW. Accounting for the observed parasitic loads, engine net electrical efficiency was calculated to be

about 30%.

Heat Recovery

The CHP system recovers heat from the engines for use in heating the anaerobic digesters. Sources of

engine heat recovery include engine exhaust, jacket water, and lube oil. According to data provided by

Point Loma WWTP staff, engine exhaust heat recovery silencers provide about 6.1 million Btu/hr per engine,

which is used for digester heating. Jacket water and lube oil heat recovery systems provide about 2.3

million and 2.0 million Btu/hr per engine, respectively, of additional digester heat. Total heat recovered

from each engine and used to maintain digester temperatures is about 10.4 million Btu/hr. The digester gas

fuel energy, based on historic source test data, is about 21.5 million Btu/hr per engine. Therefore, the total

heat recovered translates into a thermal efficiency of about 49% for each engine.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 21

A cooling system provides effluent water to the engines to prevent them from overheating. The cooling

system consists of a shell-and-tube heat exchanger and a 25 HP pump that supplies effluent cooling

water, at about 90 degrees F, to the engines.

Operation and Maintenance

Plant staff provides routine maintenance for the engines, including regular oil and spark plug changes

and cleaning of the pre-combustion chambers. An outside contractor handles any major maintenance

issues, including top end overhauls which occur at 10,000 to 12,000 hour run time intervals.

Special Considerations

Gas-Fueled Internal Combustion Engine Criticalities

Gas-fueled, Reciprocating Internal Combustion Engines (ICE) have relatively unique requirements

compared to many other types of rotating mechanical equipment. In order to meet these requirements,

gas-fueled ICE must be installed in an engineered structure. One of the most critical elements to gas-fueled

ICE operation is ventilation and airflow. Gas-fueled ICE’s are dependent upon air-cooling of the engine and

the generator. Without proper ventilation, the ICE will not receive the proper amount of air to properly cool

components. This environmental and installation requirement is a significant differentiating factor of gas-

fueled ICE compared to diesel engines, which use simpler, drop-over enclosures. Additionally, gas-fueled

ICE’s installed in CHP facilities require a significant amount of support systems and equipment to operate.

These support systems and equipment further add to the advisability of designing an engineered structure

to house the CHP facility. In order to maintain the higher efficiencies and lower emissions, control of the

intake air temperature is also required.

Support System Requirements

The support system and equipment required for gas-fueled internal combustion engines include the design

and installation of the engine cooling system, exhaust system, lube oil system, electrical components, room

ventilation, and fuel gas trains. A list of specific components within each support system is shown below:

• Cooling System – radiator, pumps, valves, plumbing, and heat exchangers.

• Exhaust System – exhaust boiler, silencers, insulation wraps, expansion tanks, and associated

plumbing.

Exhaust boilers may require a special operation licenses depending on location.

• Lube Oil System – fresh and waste oil tanks, pumps, piping, valves, flow meter.

If buried tanks are used, special regulations will apply.

• Electrical – motor control center (MCC), switchgear, controls, wiring, generator controls.

• Ventilation – fans, louvers, controls, cooling system, heating system.

• Gas Trains – structural support, valves, meters, plumbing.

The above list includes equipment for engine operation only. Most CHP facilities also include equipment for

heat recovery, and may require emissions control and/or gas cleaning equipment to meet all the ICE

manufactures requirements as well as requirements of local regulatory jurisdiction.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 22

Engine Container Solutions

Many manufacturers provide factory supplied all inclusive, self-contained containers for their ICE’s. The

containers arrive fully-equipped with the above listed support system components needed to operate the

engine installed within the metal container structure. The physical footprint for these container solutions

generally measure 8 – 10 feet in width, 35 – 50 feet in length, and 8 – 9 feet in height. The container

solutions are constructed on a reinforced metal frame and fully-assembled for delivery to the project site. In

addition to the support systems, these enclosed solutions often have a wall-separated control room, engine

room access doors, and easy, end access to allow for generator set removal during overhauls and

significant maintenance tasks. As mentioned above, this manufacturer supplied solution provides the

benefit of a fully-assembled solution to the end user. The manufacturer possesses the expertise and

experience to coordinate and assemble all of the necessary primary and support system complexities, such

as electrical wiring, mechanical piping and valving, engine room controls, and fluid storage tanks, all in

proper coordination with the operational requirements for the engine-generator set. Another option is to

have a third-party construct a container for the engine. This solution is certainly suitable for experienced,

third-party vendors with the proven capability and expertise to manufacture a full container solution.

However, due diligence is required to determine the vendor’s experience and expertise in assembling all

components for this type of solution, including structural, mechanical, electrical, and ventilation expertise.

The gas-fueled ICE container is much more robust than the typical diesel enclosure.

Rules of Thumb/Considerations

When should an owner decide to choose a container solution? When is it appropriate to install a loose

engine-generator set in a dedicated building? There are several factors to consider. Below is a list of

factors and rules of thumb to assist in determining the best application for your facility.

• Building Space – Is there existing building space suitable for installation of a loose engine-generator

set and the support systems and equipment? If yes, then strong consideration should be given to

purchasing a loose engine-generator set for installation in the building.

• Quantity of Engines - Generally, engine-generator container solutions increase the cost to purchase

a similar sized, loose engine-generator set by approximately $250,000 - $350,000 per unit while new

building construction containing all of the balance of plant may cost $800,000 - $1,200,0000.

Applying these price ranges, the magic number is three. For projects involving less than three

engine-generators, strong consideration should be given to container solutions. For projects

involving three or more engine-generators, constructing a new engine building would be the more

cost-efficient solution. The building solution also allows for consolidation of balance of support

systems and equipment such as a single control room; single, large waste and fresh storage tanks; or

consolidated switchgear. It also offers a better solution to climates that encounter both hot and

cold temperature swings. Also, larger engines may be better suited for building solutions so as a

overhead crane may be utilized for even minor repairs.

• Location – There are two primary items to evaluate when considering location; proximity to

anaerobic digesters (heat demand and engine fuel source) and the electrical interconnection

point. When considering a CHP project, electricity and heat production are the system outputs. The

physical location of the electrical interconnection and digesters will dictate the best location for the

engine-generator installation. Even if existing building space exists, if this space is physically located

a great distance from either (or both) the digesters or electrical interconnection point, the flexibility

of locating a container solution, which only requires a structurally suitable, slab foundation may be

the best solution.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 23

• Portability – Container solutions provide the benefit of an easier manner of transporting an engine-

generator set and with support systems. If you want the flexibility to consider relocating the unit to

another location or selling the unit after a certain number of operating hours, this portability may

provide a benefit. However, in general this benefit is typically secondary in nature.

• Plant Architecture – Some facilities have strict architectural plans and requirements for facilities. It is

common for plants to require all structures to be constructed of certain materials or display a certain

color. Architectural requirements can drive the purchase of loose units and support system

equipment to be installed in buildings.

• Structural Requirements - Some unique locations may have seismic or wind requirements that

dictate a more robust structure than provided by a container solution. These requirements would

drive installation of a loose engine in a dedicated building.

Both container and building installations can be successful for CHP projects using digester gas. It is critical

to understand that gas-fueled ICE have greater requirements than most rotating, mechanical equipment,

particularly compared to diesel engines. The container solutions can be very effective in providing a full-

assembled solution that provides everything needed as well as only requiring simple site preparation ahead

of installation. However, economic and other site-specific factors can make the installation of engine-

generators in a dedicated building the optimal choice.

Copyright © 2017 Water Environment Federation. All Rights Reserved.

WSEC-2017-TR-002, RBC Bioenergy Technology Subcommittee, CHP Task Force 24

Additional Resources

• National Biosolids Partnership

• Water Environment Federation

• Air Quality Permitting, WEF, 2015

• Enabling the Future: Advancing Resource Recovery from Biosolids, WEF, 2013.

• Solids Process Design and Management, WEF Press, 2012.

• Combined Heat and Power Installation Database, U.S. DOE

• CHP Deployment, U.S. DOE

• CHP Policies and incentives database (dCHPP), U.S. EPA

• CHP Resources, U.S. EPA

• Combined Heat and Power Partnership, U.S. EPA

For further Biosolids information, please see http://www.biosolids.org.

CONTACT:

Water Environment Federation

601 Wythe Street

Alexandria, VA 22314

703-684-2400

biosolids@wef.org