GE Healthcare

Biacore T200

Software Handbook

Biacore T200 Software Handbook 28-9768-78 Edition AA 1

Contents

1Introduction

1.1 System overview ............................................................................ 7

1.2 Support for use in regulated environments .............................. 8

1.3 Associated documentation .......................................................... 8

1.4 Biacore terminology ...................................................................... 8

2 Control Software – general features

2.1 Operational modes ...................................................................... 13

2.2 User interface ............................................................................... 14

2.2.1 Software help ............................................................................................. 15

2.3 Basic operation ............................................................................. 15

2.3.1 Selecting cycles and sensorgrams.................................................... 15

2.3.2 File menu...................................................................................................... 15

2.3.3 Edit menu ..................................................................................................... 17

2.3.4 View menu................................................................................................... 17

2.3.5 Run menu..................................................................................................... 19

2.3.6 Tools menu.................................................................................................. 19

2.3.7 Right-click menus ..................................................................................... 20

2.4 File storage .................................................................................... 21

2.4.1 Wizard templates and methods......................................................... 21

2.4.2 Result files.................................................................................................... 21

3Manual run

3.1 Preparing for a manual run ........................................................ 23

3.1.1 Instrument preparations ....................................................................... 23

3.2 Starting a manual run ................................................................. 24

3.3 Controlling a manual run ........................................................... 25

3.4 Ending a manual run ................................................................... 27

4 Application wizards

4.1 Wizard templates ......................................................................... 29

4.1.1 Creating and editing wizard templates .......................................... 29

4.1.2 Running wizards ....................................................................................... 30

4.2 Common wizard components .................................................... 30

4.2.1 Injection sequence ................................................................................... 30

4.2.2 Assay setup ................................................................................................. 32

4.2.3 Injection parameters............................................................................... 33

4.2.4 Sample and control sample tables ................................................... 34

4.2.5 System preparations............................................................................... 35

4.2.6 Rack positions............................................................................................ 37

4.2.7 Prepare Run protocol.............................................................................. 41

4.3 Wizard groups .............................................................................. 42

4.4 Immobilization pH scouting ....................................................... 42

2 Biacore T200 Software Handbook 28-9768-78 Edition AA

4.5 Immobilization ..............................................................................45

4.6 Regeneration scouting ................................................................50

4.7 Buffer scouting ..............................................................................54

4.8 Surface performance ...................................................................56

4.9 Binding analysis ............................................................................58

4.10 Concentration analysis ...............................................................61

4.11 Kinetics/Affinity ............................................................................65

4.12 Thermodynamics ..........................................................................70

4.13 Control experiments ....................................................................73

4.13.1 Mass transfer control.............................................................................. 73

4.13.2 Linked reactions control ........................................................................ 73

4.13.3 Evaluation of control experiments.................................................... 74

4.14 Immunogenicity ............................................................................76

5Methods

5.1 Opening methods .........................................................................77

5.2 Method structure ..........................................................................78

5.3 Method overview ..........................................................................79

5.4 General settings ............................................................................80

5.5 Assay steps ....................................................................................81

5.5.1 Base settings .............................................................................................. 82

5.5.2 Assay step preparations........................................................................ 84

5.5.3 Recurrence................................................................................................... 84

5.5.4 Number of replicates............................................................................... 85

5.6 Cycle types .....................................................................................86

5.6.1 Commands.................................................................................................. 87

5.6.2 Variables....................................................................................................... 93

5.6.3 Report points.............................................................................................. 95

5.7 Variable settings ...........................................................................97

5.8 Verification ....................................................................................98

5.9 Setup Run .......................................................................................98

5.9.1 Detection ...................................................................................................... 98

5.9.2 Variables....................................................................................................... 98

5.9.3 Cycle run list..............................................................................................100

5.9.4 System preparations.............................................................................100

5.9.5 Rack positions..........................................................................................101

5.9.6 Prepare Run Protocol............................................................................101

5.9.7 Starting the run .......................................................................................101

5.10 Requirements for assay-specific evaluation .........................101

5.10.1 Concentration analysis ........................................................................101

5.10.2 Kinetics/Affinity........................................................................................102

5.10.3 Thermodynamics....................................................................................102

5.10.4 Affinity in solution...................................................................................102

5.10.5 Immunogenicity ......................................................................................103

5.10.6 Other requirements ...............................................................................103

Biacore T200 Software Handbook 28-9768-78 Edition AA 3

6 Evaluation software – general features

6.1 User interface ............................................................................. 107

6.1.1 Organization .............................................................................................107

6.1.2 The Evaluation Explorer.......................................................................108

6.2 Basic operations .........................................................................108

6.2.1 Opening files .............................................................................................108

6.2.2 Printing evaluation results..................................................................109

6.3 Common display functions ....................................................... 109

6.3.1 Zooming the display..............................................................................109

6.3.2 Right-click menus ...................................................................................109

6.4 Predefined evaluation items .................................................... 112

6.4.1 Sensorgram...............................................................................................112

6.4.2 Plots..............................................................................................................112

6.5 Custom report points ................................................................113

6.5.1 Adding report points .............................................................................114

6.5.2 Editing and deleting report points...................................................115

6.6 Keywords .....................................................................................115

6.7 Solvent correction ......................................................................117

6.7.1 Background...............................................................................................117

6.7.2 When solvent correction should be used.....................................118

6.7.3 How solvent correction works ..........................................................119

6.7.4 Applying solvent correction................................................................119

6.8 Evaluation methods ...................................................................121

6.8.1 Creating evaluation methods............................................................121

6.8.2 Applying evaluation methods ...........................................................122

7 Data presentation tools

7.1 Sensorgram items ...................................................................... 123

7.1.1 Selecting sensorgrams for display..................................................124

7.1.2 Removing data ........................................................................................124

7.1.3 Sensorgram adjustment......................................................................125

7.1.4 Markers .......................................................................................................126

7.2 Plot items .....................................................................................127

7.2.1 Selector functions...................................................................................128

7.2.2 Table functions.........................................................................................129

7.2.3 Sorting the plot........................................................................................130

7.2.4 Fitting curves to points.........................................................................130

7.2.5 Adjusting plots for controls ................................................................132

7.2.6 Ranking .......................................................................................................134

7.3 Bar chart items ........................................................................... 135

7.3.1 Selector functions...................................................................................135

7.3.2 Display options ........................................................................................136

7.4 Report point table ...................................................................... 136

7.4.1 Displaying the report point table.....................................................136

4 Biacore T200 Software Handbook 28-9768-78 Edition AA

8 Concentration analysis

8.1 Requirements for concentration evaluation .........................141

8.1.1 Calibrated measurements..................................................................141

8.1.2 Calibration-free measurements.......................................................141

8.2 Evaluating calibrated concentration analyses .....................142

8.2.1 Calibration curves...................................................................................142

8.2.2 Calibration trends...................................................................................144

8.2.3 Control samples ......................................................................................146

8.2.4 Samples ......................................................................................................147

8.2.5 Custom models for calibration curves ..........................................148

8.2.6 Evaluating combined result sets.....................................................149

8.3 Evaluating calibration-free measurements ..........................150

8.3.1 Selecting samples...................................................................................150

8.3.2 Performing the evaluation..................................................................155

8.3.3 Interpreting the results.........................................................................156

8.3.4 Fitting model.............................................................................................157

9 Kinetics and affinity analysis

9.1 Requirements for kinetics and affinity evaluation ...............160

9.2 Evaluating kinetics and affinity in single mode ....................161

9.2.1 Basic procedure ......................................................................................161

9.2.2 Multiple ligand densities......................................................................169

9.3 Batch mode evaluation .............................................................170

9.4 Quality assessment for kinetics evaluation ..........................172

9.4.1 The Quality Control tab........................................................................172

9.4.2 Statistical parameters ..........................................................................175

9.4.3 Components of the fit ...........................................................................177

9.4.4 Check kinetic data..................................................................................177

9.5 Quality assessment for affinity evaluation ...........................179

9.6 Summarizing kinetics and affinity results .............................180

9.6.1 Creating kinetic summaries ...............................................................180

9.6.2 Basic summary presentation ............................................................180

9.6.3 On-off rate maps.....................................................................................183

9.7 Curve fitting principles ..............................................................184

9.7.1 Fitting procedure ....................................................................................184

9.7.2 Local and global parameters ............................................................185

9.8 Predefined models ......................................................................186

9.8.1 Kinetics – 1:1 binding............................................................................187

9.8.2 Kinetics – Bivalent Analyte .................................................................188

9.8.3 Kinetics – Heterogeneous Analyte ..................................................189

9.8.4 Kinetics – Heterogeneous Ligand....................................................191

9.8.5 Kinetics – Two State Reaction...........................................................193

9.8.6 Affinity – Steady State 1:1...................................................................195

9.9 Creating and editing models ....................................................195

9.9.1 Interaction models for kinetics .........................................................196

9.9.2 Equation models for kinetics .............................................................200

9.9.3 Models for steady state affinity ........................................................202

Biacore T200 Software Handbook 28-9768-78 Edition AA 5

10 Thermodynamic analysis

10.1 Background .................................................................................203

10.1.1 Equilibrium thermodynamics ............................................................203

10.1.2 Transition state thermodynamics ...................................................204

10.2 Performing thermodynamic analysis ..................................... 205

11 Affinity in solution

11.1 Conventions and background ..................................................209

11.1.1 Experimental setup................................................................................209

11.1.2 Evaluation principles.............................................................................209

11.2 Requirements for affinity in solution ......................................210

11.3 Evaluation of affinity in solution .............................................211

12 Immunogenicity

Appendix A Data import and export

A.1 Exporting data ............................................................................217

A.1.1 Export functions ......................................................................................217

A.2 Importing data ............................................................................ 218

A.2.1 Control Software.....................................................................................218

A.2.2 Evaluation Software..............................................................................221

Appendix B Method examples and recommendations

B.1 Affinity in solution ...................................................................... 223

B.2 Calibration-free concentration analysis ................................224

B.2.1 Assay steps and general settings....................................................224

B.2.2 Cycle types.................................................................................................224

B.2.3 Variable settings......................................................................................225

B.2.4 Setup Run...................................................................................................226

B.3 CAP single-cycle kinetics ..........................................................227

B.3.1 Assay steps................................................................................................227

B.3.2 Sample analysis cycle for Sensor Chip CAP................................228

B.4 GST kinetics .................................................................................230

B.5 Inject and Recover .....................................................................232

B.6 Kinetics heterogeneous analyte .............................................. 234

B.7 L1 liposome capture .................................................................. 234

B.8 LMW kinetics and LMW Screen ................................................235

B.9 LMW single-cycle kinetics ........................................................237

B.10 Single-cycle kinetics .................................................................. 237

Index.............................................................................................. 239

6 Biacore T200 Software Handbook 28-9768-78 Edition AA

Biacore T200 Software Handbook 28-9768-78 Edition AA 7

Introduction 1

1 Introduction

Biacore™ T200 is a high performance system for analysis of biomolecular

interactions, based on GE Healthcare’s surface plasmon resonance (SPR)

technology. The Control Software supplied with the system offers easy-to-use

wizards for assay development and common applications together with flexible

facilities for designing custom analysis methods using a graphical interface

called Method Builder. Results are evaluated in separate Evaluation Software

designed for efficient and flexible evaluation, with dedicated functions for

common applications.

This Handbook describes in detail how to use the Control and Evaluation

Software.

1.1 System overview

Instrumentation in the Biacore T200 system is described in full in the

Biacore T200 Instrument Handbook. Important features relevant to software

operation include:

• Biacore T200 supports simultaneous analysis in up to four flow cells

connected in series. The flow cells are arranged in pairs (Fc1-2 and Fc3-4)

with minimum dead volume between the flow cells in a pair to provide

accurate reference subtraction.

• The sample compartment accommodates one microplate (96- or 384-well,

regular or deep-well capacity) and one reagent rack for reagent vials. A

combined sample and reagent rack can be used in place of the separate

microplate and reagent rack.

• Material that binds to the sensor surface during sample injection can be

recovered in a small volume of liquid for further analysis by e.g. mass

spectrometry.

• The temperature in the sample compartment is controlled separately from

the analysis temperature, allowing samples to be kept at one temperature

while analysis is performed at another. Samples equilibrate to the analysis

temperature during injection into the flow cell. The analysis temperature

can be varied during a run, and the sample compartment temperature

can be set to follow the analysis temperature if desired.

• The system includes a buffer selector valve, allowing analysis to be

performed in up to four different buffers in the same unattended run.

1 Introduction

1.2 Support for use in regulated environments

8 Biacore T200 Software Handbook 28-9768-78 Edition AA

1.2 Support for use in regulated environments

Support for use in regulated (GxP

1

) environments is provided in an optional

package that adds appropriate functionality to the Biacore T200 software.

Functions for GxP support are described in a separate Biacore T200 GxP

Handbook. Descriptions of software in the current Handbook apply to

installations both with and without the GxP package unless otherwise stated.

1.3 Associated documentation

This Handbook describes Biacore T200 Control Software and Evaluation

Software, version 1.0. Any functionality that is added in optional add-on

modules is described in separate documentation.

Biacore T200 Instrument Handbook describes the instrumentation in the

Biacore T200 system, with instructions for operation, maintenance and

troubleshooting.

Biacore T200 GxP Handbook describes functionality added with the optional

GxP package, together with some recommendations for using the system in a

regulated environment.

Biacore T200 Immunogenicity Handbook describes the use of specialized

functions in the software for immunogenicity studies.

Other general handbooks and documentation describing the technology are

available from GE Healthcare. Information may also be found on the Internet at

www.gelifesciences.com/biacore.

1.4 Biacore terminology

Biacore monitors the interaction between two molecules, of which one is

attached to the sensor surface and the other is free in solution. The following

terms are used in the context of work with Biacore systems (see Figure 1-1):

• The partner attached to the surface is called the ligand. Attachment may

be covalent or through high affinity binding to another molecule which is

in turn covalently attached to the surface. In the latter case the molecule

attached to the surface is referred to as the capturing molecule.

Note: The term “ligand” is applied here in analogy with terminology used in

affinity chromatography contexts, and does not imply that the

surface-attached molecule is a ligand for a cellular receptor.

•The analyte is the interacting partner in solution for which the

concentration is to be measured. In direct binding assays, the analyte

1

GxP is used as a generic abbreviation for GLP (Good Laboratory Practice), GMP (Good

Manufacturing Practice) and GCP (Good Clinical Practice).

Biacore T200 Software Handbook 28-9768-78 Edition AA 9

Introduction 1

binds directly to the ligand. In inhibition assays, the concentration of

analyte is measured indirectly through binding of an additional molecule.

Figure 1-1. Ligand, analyte and capturing molecule in relation to the sensor surface.

• Regeneration is the process of removing bound analyte from the surface

after an analysis cycle without damaging the ligand, in preparation for a

new cycle.

• Response is measured in resonance units (RU). The response is directly

proportional to the concentration of biomolecules on the surface.

•A sensorgram is a plot of response against time (see Figure 1-2), showing

the progress of the interaction. This curve is displayed directly on the

computer screen during the course of an analysis. Sensorgrams may be

analyzed to provide information on the rates of the interaction.

• In many assay situations, sample passes over two or more flow cells in

series, where one flow cell (usually the first) serves as a reference while

ligand is attached in the other flow cell(s). Surfaces with ligand are referred

to as active: blank surfaces used for reference purposes are reference.

• A particular sensorgram is referred to as a curve in several contexts in the

software. This terminology is used to distinguish between different classes

of sensorgram that recur within a run: for example, measurements on one

active and one reference surface can generate separate curves for each

of the two flow cells and a third reference-subtracted curve (active minus

reference)

•A report point records the response on a sensorgram at a specific time

averaged over a short time window, as well as the slope of the sensorgram

over the window. The response may be absolute (above a fixed zero level

determined by the detector) or relative to the response at another

specified report point.

1 Introduction

1.4 Biacore terminology

10 Biacore T200 Software Handbook 28-9768-78 Edition AA

Figure 1-2. Schematic illustration of a sensorgram. The bars below the sensorgram

curve indicate the solutions that pass over the sensor surface.

Biacore T200 Software Handbook 28-9768-78 Edition AA 11

Control Software

12 Biacore T200 Software Handbook 28-9768-78 Edition AA

Biacore T200 Software Handbook 28-9768-78 Edition AA 13

Control Software – general features 2

2 Control Software – general features

2.1 Operational modes

Biacore T200 Control Software offers three modes of operation:

• Manual run provides interactive control of the instrument operation,

executing commands singly as they are issued. This mode is most useful

for ad hoc experiments involving one or a few injections, such as testing

the response obtained from injection of a single sample.

• Application wizards provide guidance in setting up experiments for assay

development and execution. Separate wizards are offered for different

purposes such as ligand immobilization, concentration determination or

measurement of kinetic constants. Each wizard consists of an ordered

series of dialog boxes, ensuring that the essential features of the

application setup are correctly defined.

• Methods provide greater flexibility (and conversely less guidance) in setting

up applications, allowing customized applications that are not covered by

wizards. Methods are defined in a graphical interface called Method

Builder, which is designed to provide full flexibility in method definition

while retaining a simple interface for running assays based on established

methods. Application wizard templates may be opened in Method Builder

to provide a starting point for further refinement of application setup.

Predefined methods are also provided as help in defining methods for

selected purposes (see Appendix B).

Each of these modes of operation is described in more detail in the following

chapters.

2 Control Software – general features

2.2 User interface

14 Biacore T200 Software Handbook 28-9768-78 Edition AA

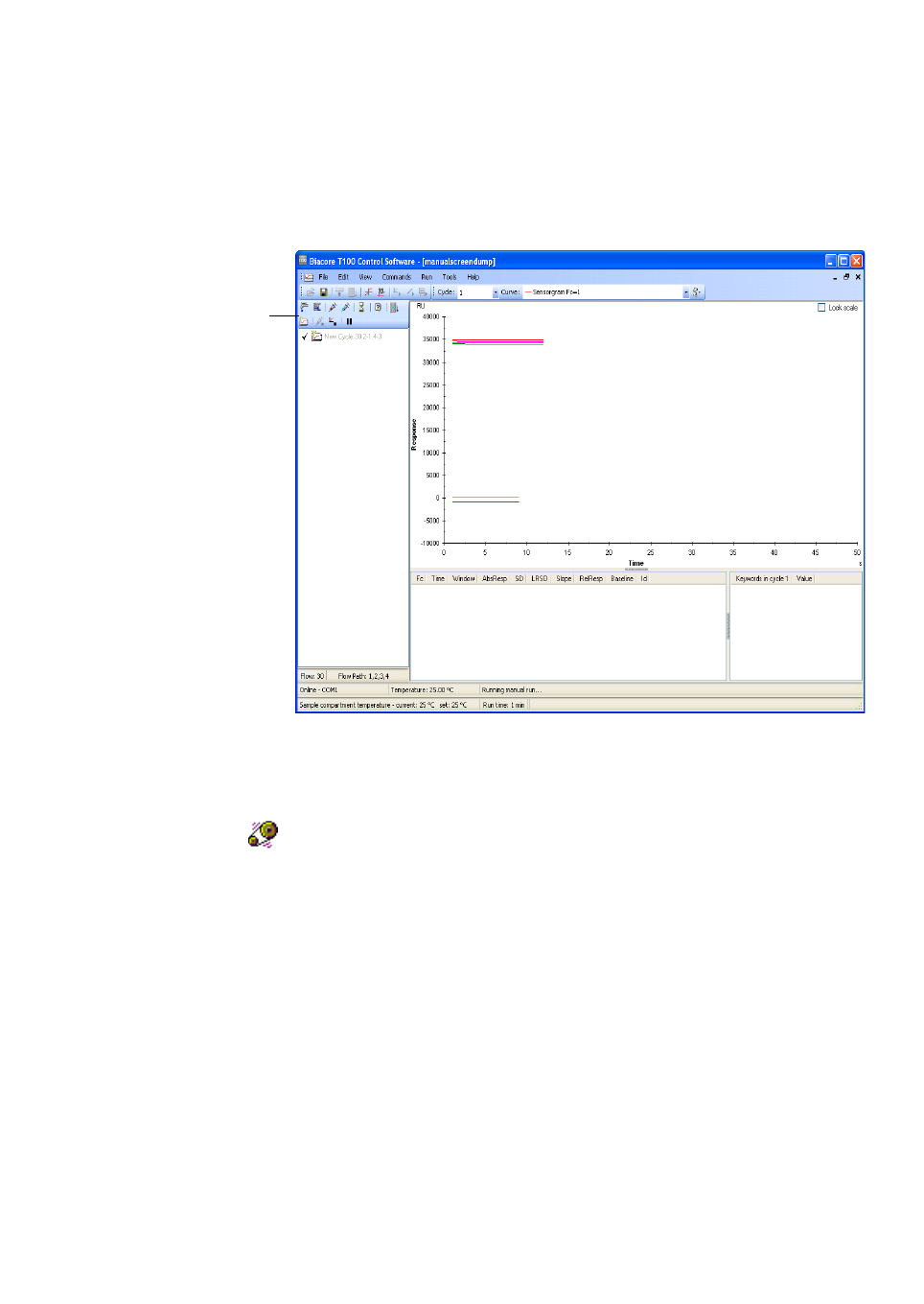

2.2 User interface

The main screen in the control software is divided into the following areas

•The menu and toolbar provide access to control commands.

•The event log records settings at the start of the run and instrument

control events during the run. The event log is displayed in a separate

window, opened by clicking on the Event Log button at the right of the

toolbar.

•The sensorgram window displays the sensorgrams for the current run or

the currently open file.

•The report point table lists report points for the currently displayed cycle.

Report points record the response at a set time and are defined

automatically: custom report points can also be added in methods, or

after the run in either the Control Software or the Evaluation Software.

•The keyword table lists keywords for the currently displayed cycle.

Keywords are defined automatically in wizard runs, or in the method for

method runs.

•The status bar displays the instrument status, including the temperature of

the detector and the sample compartment. The content of the status bar

varies between different situations: for wizard- and method-based runs,

the elapsed run time and the estimated total run time are included.

Menu and toolbar

Event log

Sensorgram window

Report point table

Keyword table

Status bar

Biacore T200 Software Handbook 28-9768-78 Edition AA 15

Control Software – general features 2

2.2.1 Software help

Software help is available at any time from the Help menu. Context-specific help

for dialog boxes is provided through Help buttons in the boxes.

2.3 Basic operation

2.3.1 Selecting cycles and sensorgrams

During a run, the current cycle is displayed by default. You can choose which

cycle to display in the Cycle selector, but the display will revert to the current

cycle when a new cycle is started. For a completed run, choose which cycle to

display with the Cycle selector in the toolbar:

The Curve selector determines which curve in the cycle is current in the display.

Options in the View menu (Section 2.3.4) control which curves are displayed in

the sensorgram window.

2.3.2 File menu

The Open/New options for wizard templates and methods create new wizard

templates and methods, and open existing templates and methods for editing

or for starting a run.

Open opens result files. Most result files just display the sensorgrams and tables.

Files from immobilization and regeneration scouting wizards also display a

summary window showing the results of the run (see Sections 4.5 and 4.6).

Save and Save As save the results as a Biacore results file (extension .blr).

Export exports the current results to a file in Microsoft Excel or XML format, or

exports the contents of the report point table to a tab-separated file. See

Appendix A for details of the export format.

2 Control Software – general features

2.3 Basic operation

16 Biacore T200 Software Handbook 28-9768-78 Edition AA

Print prints a hard-copy of the results. Select the printer to use and check the

items you wish to print.

Sensorgrams may be printed as follows:

Note: In order to maintain report layout, the print orientation is fixed regardless

of the printer settings in Windows.

Properties shows detailed properties of the currently opened run, including the

properties of the sensor chip used in the run.

When you close the software with Exit while the instrument is still switched on,

you may choose to shut down the instrument for a shorter or longer period if

required. See the Biacore T200 Instrument Handbook or the on-line help for

more details.

None No sensorgrams will be printed.

Current cycle The current cycle will be printed with the View:Show… setting

and scale as shown on the screen.

Range and

All cycles

Multiple cycles will be printed. For Range, enter a range or

cycle numbers separated by commas (e.g. 4-16,19,22).

All curves will be included in each cycle regardless of the

View:Show… setting. Sensorgrams will be printed at full scale

unless the Lock Scale box is checked in the sensorgram

window, in which case the current scaling will be applied to

all cycles (with this setting, some sensorgrams may appear to

be empty).

Biacore T200 Software Handbook 28-9768-78 Edition AA 17

Control Software – general features 2

2.3.3 Edit menu

Options in the Edit menu allow you to add, edit and delete report points. Report

points are created automatically and are used in various evaluation contexts.

You should in general avoid editing or deleting report points that are created

automatically.

Editing operations for report points in the Control Software may be applied to

single report point instances or to all instances of the report point in the current

cycle. Note that editing operations are not applied to multiple cycles.

Report points created in the Control Software cannot be edited in the Evaluation

Software. The Evaluation Software offers functions for creating and editing

custom report points that can be applied to all cycles in the run in a single

operation. This is usually preferable to adding report points in the Control

Software.

2.3.4 View menu

Chip Properties opens a dialog box that displays the properties of the currently

docked sensor chip. The Ligand column is empty for flow cells that have not

been used, and shows [Blank] for flow cells that have been prepared as a blank

reference surface by activation and deactivation. The text [Incomplete results]

indicates that the immobilization run was interrupted (by for instance user

intervention or power failure) before it could be completed.

2 Control Software – general features

2.3 Basic operation

18 Biacore T200 Software Handbook 28-9768-78 Edition AA

Properties for the sensor chip used in a currently open run may be found under

File:Properties (Section 2.3.2).

Title sets a title in the sensorgram window. The default title is the assay step

name.

Scale sets the scale of the sensorgram window:

If you set Auto scale, the scale will be adjusted if necessary to accommodate

the full data range of the currently displayed cycle. During a run, the scale is

adjusted at intervals as more data is collected. Check the Lock scale box in the

top right corner of the sensorgram window to lock the scale to the current

settings.

Adjust Scale sets the scale to the full data range. This will not affect the Auto

scale setting in the Scale dialog. Adjust Scale overrides but does not turn off the

Lock scale setting.

To scale the sensorgram display interactively, drag with the cursor over the area

to be scaled. Double-clicking in the display or choosing View:Unzoom restores

the previous zoom setting.

Reference line toggles display of a movable vertical line in the sensorgram

window, together with a separate small window that shows the response and

time coordinates at the reference line for the current curve. Use the Curve

selector in the toolbar (see Section 2.3.1) to set the current curve. Drag the

reference line to move it. When the reference line is displayed, choosing

Baseline sets a baseline at the current reference line position, and the

coordinates window shows the response relative to that baseline.

Biacore T200 Software Handbook 28-9768-78 Edition AA 19

Control Software – general features 2

The options Show Only Current Curve, Show Curves of Same Type and Show

All Curves control which curves are displayed in the sensorgram window. Curve

types distinguish between unsubtracted and reference-subtracted curves.

Choose the Event Log option or click on the Event Log button at the right of the

toolbar to display the event log window.

Choose the Wizard Template or Method options to display the wizard or

method definition for the run. You can edit the definition and save it as a new

wizard template or method. You cannot however change the original definition

that is saved together with the result file.

Notebook opens a notebook window where details of the run may be recorded.

The notebook is only available during a run or for a completed result file. The run

notebook is saved with the result file and can be viewed in the Evaluation

Software.

For some wizard runs and for test tools, the Wizard Results option opens a

window showing the results of the run. All other runs are evaluated in the

Evaluation Software.

Sensorgram Markers controls display of report point and event markers and

labels in the sensorgram window.

2.3.5 Run menu

The options in the Run menu are used to start the different types of runs (see

Chapters 3–5.

2.3.6 Tools menu

Options in the Tools menu control instrument operations outside the context of

runs.

Prime flushes the flow system with fresh buffer. There is an option to include

Prime at the beginning of each wizard- or method-based run. Use the menu

option when you want to flush the system at other times (e.g. before a manual

run).

Shutdown starts the procedure for shutting down the instrument for long

periods of time (more than 7 days). The procedure displays necessary

instructions on the screen. Details of the shutdown procedure are given in the

Biacore T200 Instrument Handbook.

Standby puts the instrument in standby mode, which maintains a low buffer or

water flow through the flow system for up to 7 days. Leaving the instrument in

standby mode when not in use is generally recommended. The instrument is

2 Control Software – general features

2.3 Basic operation

20 Biacore T200 Software Handbook 28-9768-78 Edition AA

automatically put in standby mode at the end of a run. Use the menu option if

standby has been stopped and you want to restart it.

Stop Standby stops standby mode.

Eject Rack ejects the rack tray from the sample compartment. The rack may be

ejected during setup for wizard- and method-based runs, and at any time

during a manual run. Use the menu option or the toolbar button when you want

to eject the rack at any other time.

Rack Illumination switches the illumination in the sample compartment on or

off. The illumination helps you to see in the sample compartment but does not

otherwise affect instrument function.

Insert Chip and Eject Chip are used for docking and undocking the sensor chip

respectively. More details are given in Chapter 4 of the Biacore T200 Instrument

Handbook.

Set Temperature sets the sample compartment and analysis temperature.

More details are given in Chapter 4 of the Biacore T200 Instrument Handbook.

Preferences controls aspects of file storage and data import (see Section 2.4),

and the time to automatic retraction of the rack tray.

More Tools provides access to maintenance, test and service tools. Details are

given in Appendix B of the Biacore T200 Instrument Handbook.

2.3.7 Right-click menus

Right-clicking with the mouse in many windows opens context menus specific

for the window.

Sensorgram window

Scale opens the same dialog as the View:Scale option (Section 2.3.4).

Copy Graph copies the sensorgram window exactly as displayed to the

Windows clipboard. Use this option to insert a copy of the sensorgram window

into other programs such as presentation software.

Export Curves exports data for the currently displayed curves to a text file.

Entire curves are exported regardless of the scale of the display. The exported

data includes report points and event marker times if these are displayed in the

sensorgram window. See Appendix A for more details of the export format.

CAUTION

The rack tray automatically moves into the instrument a preset time after it

has been ejected. The time to auto-close is set in Tools:Preferences.

A timer in the dialog indicates when the rack tray will be automatically

moved into the instrument.

Biacore T200 Software Handbook 28-9768-78 Edition AA 21

Control Software – general features 2

Gridlines controls display of gridlines in the sensorgram window.

Report point table

The right-click menu options for the report point table correspond to the

Edit:Report Points menu options.

Notebook

Right-click menu options in the notebook represent standard Windows editing

functions.

2.4 File storage

2.4.1 Wizard templates and methods

Wizard templates are saved in files with a file name extension .bw**, where **

represents an abbreviation that identifies the wizard (e.g. a wizard template for

concentration analysis has the extension .bwConc).

Methods are saved in files with the file name extension .Method.

Note: The extension will not be displayed if the setting Hide file extensions for

known file types is selected in the Windows Explorer folder options.

Turning this setting off can help you to identify file types in dialog boxes.

Templates and methods may be saved in any location when the optional

Biacore T200 GxP Package is not installed. A folder structure under the default

location as specified on the Folders tab in Tools:Preferences is however

recommended, since files in this location are handled preferentially in the

Open/New dialog boxes for wizards and templates (see Section 4.1.1).

2.4.2 Result files

Results are saved in files with the file name extension .blr. Result files from

wizard- or method-based runs contain a copy of the wizard template or method

as well as the results of the run.

2 Control Software – general features

2.4 File storage

22 Biacore T200 Software Handbook 28-9768-78 Edition AA

Biacore T200 Software Handbook 28-9768-78 Edition AA 23

Manual run 3

3 Manual run

Manual run allows you to control a run interactively. All settings except

temperature and choice of microplate and/or reagent rack can be changed

during the run. Commands are placed in a queue if the instrument is busy when

a command is issued: queued commands that have not yet been started can be

edited or deleted from the queue.

The results of a manual run are saved in a normal result file, and can be

evaluated in the Evaluation Software. There are however no predefined

keywords associated with the run, and the results cannot be evaluated with the

Evaluation Software tools for concentration, kinetics/affinity, thermodynamics

or immunogenicity.

3.1 Preparing for a manual run

3.1.1 Instrument preparations

The integrated instrument preparation steps that are included with wizard- and

method-based runs are not supported for manual run. The instrument should

therefore be prepared using options from the Tools menu.

1 Dock the chip that you want to use, and immobilize ligand on the surface

(see Section 4.5) if this has not already been done.

2Choose Tools:Prime to flush the flow system with fresh buffer.

3Choose Normalize from the Maintenance Tools section of Tools:More

Tools if the detector has not been normalized since the chip was docked. (In

many cases, the detector will have been normalized in connection with

ligand immobilization. However, you may need to perform the operation

again if the chip has been undocked and re-docked after immobilization.)

4Choose Tools:Set Temperature and set the analysis and sample

compartment temperatures. Wait until the analysis temperature is stable

(as shown in the status bar) before starting the run.

5 Prepare your samples and reagents in the microplate and/or reagent rack.

Note the rack positions and volumes of samples that you prepare: there is

no software support in manual run for identifying samples or monitoring

the volume of liquid in the autosampler positions. You insert the samples as

part of the starting procedure for the run. You can also add samples during

the run.

3Manual run

3.2 Starting a manual run

24 Biacore T200 Software Handbook 28-9768-78 Edition AA

3.2 Starting a manual run

Choose Run:Manual Run to start a manual run.

Choose the initial settings for flow rate, flow path and reference subtraction. You

can change the flow rate at any time during the run. You can change the flow

path at any time: during a cycle, the available options are restricted by the

choice made when the cycle is started.

Choose the rack and microplate settings. These will apply throughout the run

and cannot be changed.

Click Eject Rack to eject the rack tray so that you can load your samples.

Click Start to start the run. You will be asked to specify a result file name before

the run actually starts.

Biacore T200 Software Handbook 28-9768-78 Edition AA 25

Manual run 3

3.3 Controlling a manual run

Control the manual run from the command buttons in the main window or the

options in the Command menu:

Commands are executed immediately if the instrument is idle. With a few

exceptions (noted in the detailed descriptions below), commands issued when

the instrument is busy are placed at the end of a queue. The queue is listed in

the left-hand panel, with commands that have been executed in gray text and

those that are pending in black text. The command currently being executed is

marked with a “working” icon.

Right-click on a pending command for a menu with options for:

• editing the command

• inserting a new command before the selected command (you choose the

command to insert from a dialog box)

• deleting the command

You can also use the right-click menu to copy selected command or commands

and paste them elsewhere in the queue. The Copy function works with both

completed and pending commands.

Command

buttons

3Manual run

3.3 Controlling a manual run

26 Biacore T200 Software Handbook 28-9768-78 Edition AA

Flow rate

Sets the flow rate to a new value.

Flow path

Changes the flow path. During a cycle, you can only select a flow path within a

range allowed by the setting chosen when the cycle was started (for example, if

the current setting is Flow path 1-2, you cannot extend it to Flow path 1-2-3-4).

Sample injection

Injects sample. Choose the position from which the sample will be taken and

specify a contact time. Positions that can be chosen are determined by the rack

settings in the manual run start-up dialog. Make sure that the chosen position

contains enough sample for the injection. The required volume for the specified

contact time is indicated in the dialog box.

Regeneration injection

Injects regeneration solution. Choose the position from which the solution will be

taken and specify a contact time. Positions that can be chosen are determined

by the rack settings in the manual run start-up dialog. Make sure that the

chosen position contains enough solution for the injection. The required volume

for the specified contact time is indicated in the dialog box.

Check High viscosity solution if your regeneration solution has a relative

viscosity higher than about 3 (corresponding to about 35% glycerol or 40%

ethylene glycol at 20°C). This will adjust the injection procedure to ensure correct

handling of viscous solutions, and will limit the maximum contact time that can

be specified.

Wait

Inserts a Wait command in the queue, causing the instrument operation to

pause for the specified time period. Buffer continues to flow over the sensor

surface during the Wait period and data collection continues.

Eject Rack Tray

Ejects the rack tray so that you can load more samples. Do not change the type

of microplate or reagent rack on the tray.

This command is inserted immediately after the command currently under

execution, rather than at the end of the queue, so that the rack tray will be

ejected as soon as the current command is completed. If you want to place the

command later in the queue, use the right-click menu in the queue panel to

insert the command at the appropriate place.

Biacore T200 Software Handbook 28-9768-78 Edition AA 27

Manual run 3

New Cycle

Starts a new cycle. You can choose a new flow path and reference subtraction

setting for the new cycle, independently of the setting in the current cycle.

Stop <command>

Stops the command currently being executed. The icon changes to show the

command that will be stopped, or is gray if the current command cannot be

stopped (e.g. it is not possible to stop an Eject Rack Tray command).

Stop Run

Finishes the run.

Pause Run

Pauses the run until a Resume Run command is issued. Buffer continues to flow

over the sensor surface while the run is paused. Data collection continues

during the pause.

Resume Run

Resumes a run that is paused.

Add report point

Adds a report point to the sensorgram.

Help

Displays help for the manual run.

3.4 Ending a manual run

To end a manual run:

1Issue a Stop Run command. The command will normally be placed at the

end of the queue. If you want to stop the run before the queue is completed,

use the right-click menu in the queue panel to delete commands from the

queue or to insert the Stop Run command in the appropriate position.

2Choose Tools:Eject Rack to eject the rack tray and remove your samples

and reagents.

3Choose Tools:Eject Chip to undock the chip if desired.

3Manual run

3.4 Ending a manual run

28 Biacore T200 Software Handbook 28-9768-78 Edition AA

Biacore T200 Software Handbook 28-9768-78 Edition AA 29

Application wizards 4

4 Application wizards

Application wizards guide you through the procedure of setting up common

applications, with recommendations and settings based on GE Healthcare’s

expertise in the field of SPR-based interaction studies. Wizards are an ideal

starting point for inexperienced or infrequent users, since they offer a structured

sequence of settings that covers all essential aspects of the assay in question.

Wizard settings can be saved in templates for later use. Advanced users can

open wizard templates in Method Builder for more flexible assay design (see

Chapter 5).

4.1 Wizard templates

An application wizard consists of a series of dialog boxes that takes you through

the steps in setting up the application. Settings in the dialog boxes may be saved

in wizard templates, so that opening a template will present the saved settings

in each dialog box.

Normally, a wizard template is saved when all steps have been defined, so that

the template represents a complete assay definition including sample details if

desired. If a wizard sequence is closed before reaching the last step, however,

you are given an opportunity to save the template, which will then contain

settings as far as they have been defined.

4.1.1 Creating and editing wizard templates

To create a new wizard template or edit an existing template, choose

File:Open/New Wizard Template and select the type of wizard in the dialog box.

Click New to create a new template, or navigate to the folder where your

template is stored, select the template and click Open to edit an existing

template.

The top-level folder for wizard templates is defined under Tools: Preferences

(see Section 2.4). You can navigate between subfolders under the top level in the

dialog box, but you cannot access templates outside the top-level folder directly

from within the dialog box. Click Browse to navigate freely in the computer file

structure and open wizard templates stored in other locations.

Note: The Open/New Wizard Template dialog box only lists templates of the

selected type, but the Browse dialog may list all types. Template types are

identified by the file extension, which may or may not be displayed

according to your Windows Explorer settings (see Section 2.4.1).

4 Application wizards

4.2 Common wizard components

30 Biacore T200 Software Handbook 28-9768-78 Edition AA

4.1.2 Running wizards

When you start a run based on a wizard template, the template settings are

displayed as you step through the wizard. You can change settings for the

particular run if desired: the changes are not saved in the wizard template

unless you explicitly request this with the Save wizard template option. Setting

used for the run are stored in the result file and can be examined and saved as

a new wizard template from the completed run.

4.2 Common wizard components

Several dialogs are common to a number of wizards, with equivalent functions

and only minor differences. These dialogs are described in the current section.

Any wizard-specific variations in these common components are described in

the sections on the respective wizards below.

4.2.1 Injection sequence

This dialog determines the sequence of injections in the wizard analysis cycle.

Some injections are not supported in certain wizards (e.g. the kinetics wizard

does not support enhancement injections).

Detection settings

Select the flow path for the analysis. The setting will apply throughout the whole

wizard run. The available flow paths vary between the different wizards

according to wizard purpose.

Biacore T200 Software Handbook 28-9768-78 Edition AA 31

Application wizards 4

The detection is automatically set to the same settings as the flow path, so that

sensorgrams are recorded only from the flow cells used.

When reference subtraction is used together with ligand capture (Section 4.2.1),

the captured ligand passes over the active surface but not the reference surface

(for example, with Flow path set to 2-1, the ligand is injected in flow cell 2 but

not flow cell 1). If the Flow path setting does not use reference subtraction,

ligand is injected in all flow cells included in the flow path.

Chip type

Select the sensor chip type for the analysis. This choice will determine certain

assay settings in accordance with the requirements of the sensor chip (for

example, selecting Sensor Chip NTA will automatically check the Ligand capture

option and include an injection of nickel before the ligand capture step, and will

suggest 0.35 M EDTA as a conditioning solution).

Choose chip type Custom if you are using a chip type that is not listed.

Injections

Check the injections that you want to include. The illustration panel shows the

sequence of included injections. Injections have the purposes listed below. There

may be additional injections for some sensor chip types (for example injection

of nickel for Sensor Chip NTA).

Ligand capture Intended for ligand solution in applications that use a

capturing approach to attach the ligand to the surface. The

same solution will be used for the capture injection in all

cycles: you cannot vary the captured ligand within the

context of one wizard run.

The flow path for capture solution depends on the settings for

detection (see above).

Sample This is the sample to be analyzed. The solution used for the

sample injection is normally different in different cycles, and

is specified in the sample table at a later stage in the wizard.

The sample injection is required in all wizards.

Enhancement Intended for injection of a secondary reagent that binds to

analyte on the surface, typically used either to amplify the

response obtained from the analyte or to enhance the

specificity of analyte detection. The same solution will be

used for the enhancement injection in all cycles in the run.

Regeneration One or two regeneration injections may be included, which

may use the same or different solutions. The same

regeneration procedure is used throughout the run.

4 Application wizards

4.2 Common wizard components

32 Biacore T200 Software Handbook 28-9768-78 Edition AA

4.2.2 Assay setup

Common features of the assay setup dialog are choice of conditioning and

start-up cycles at the beginning of the run.

Conditioning cycle

A conditioning cycle prepares the sensor chip for the assay by washing with one

or more injections of the specified solution. The surface is not regenerated after

the conditioning injections. The conditioning cycle is run once at the beginning

of the assay.

Conditioning cycles are recommended for certain chip types, to prepare the

surface before starting the assay. Examples are Sensor Chip NTA which should

be conditioned with 0.35 M EDTA to remove any bivalent metal ions, Sensor Chip

L1 and HPA which may be conditioned with for example octylglucoside to

remove any lipids on the surface, and Sensor Chip CAP which should be

conditioned with regeneration solution. Conditioning cycles are generally not

appropriate for sensor chips where the ligand or capturing molecule is attached

to the surface before the assay wizard is started.

If you run several assays after each other without undocking the chip between

assays, conditioning is generally only required for the first assay.

Start-up cycles

Start-up cycles are identical to analysis cycles except that the sample is

replaced by a dummy sample (often buffer). The response from a newly

prepared or newly docked sensor chip often shows some instability during the

first few cycles, and start-up cycles allow the response to stabilize before the

first analysis cycle is performed. Three start-up cycles are generally

recommended for most assay purposes, to ensure a stable response in the

analysis. Start-up cycles are treated separately from analysis cycles in the

evaluation software.

Biacore T200 Software Handbook 28-9768-78 Edition AA 33

Application wizards 4

Start-up cycles are run at the beginning of the experiment (after the

conditioning cycle), and also directly after buffer change (in the Buffer Scouting

wizard) and temperature change (in the Thermodynamics wizard).

4.2.3 Injection parameters

The Injection parameters dialog specifies details of injections selected in the

Injection sequence. Injections for which the conditions are fixed in the software

are not listed.

Details of this dialog box may vary according to the injections selected and the

particular wizard. Some features may be generalized:

Parameter limits

Flow rates can be set between 1 and 100 µl/min in increments of 1 µl/min.

Permitted ranges for injection contact times are determined by the flow rate

together with the limits for injected volumes, which are 2–350 µl for normal

solutions and 5-100 µl for viscous regeneration solutions (see below).

Note: The injected volume of solution is determined by the combination of flow

rate and contact time, rounded to the nearest whole number. At low flow

rates, this can result in actual contact times that differ from the requested

times: for example, at 1 µl/min a requested contact time of 200 s

(requiring 3.3 µl solution) will result in an actual contact time of 180 s

(solution volume rounded to 3 µl).

4 Application wizards

4.2 Common wizard components

34 Biacore T200 Software Handbook 28-9768-78 Edition AA

Stabilization time after injection

This function is available after a capture injection and after the last injection in

the sequence. For capture injections, a stabilization time can be useful if a

fraction of the ligand dissociates rapidly. Including a stabilization time to allow

for such dissociation can help to improve reproducibility.

A stabilization time may be used after the last injection instead of regeneration

for systems where analyte dissociates completely from the surface.

Exposure of the surface to regeneration solution can often lead to transient

changes in the baseline. Inclusion of a stabilization time after regeneration

helps to ensure a stable baseline for the next cycle.

Sample injection

Normally, the injected sample solution is specified in a separate sample table.

Some wizards (e.g. Surface Performance) use only a single sample solution that

is specified together with the other injection parameters in this dialog box.

Regeneration

The parameters for regeneration include a check-box for High viscosity

solution. Check this box if the regeneration solution has a relative viscosity

higher than about 3 (corresponding to about 35% glycerol or 40% ethylene

glycol at 20°C). This will modify the injection procedure for better handling of

viscous solutions. The maximum injected volume is limited to 100 µl for viscous

solutions.

4.2.4 Sample and control sample tables

Details of samples and control samples (where applicable) are entered in the

Sample and Control Samples steps respectively. The details of these steps differ

according to the wizard purpose, but the following general features may be

noted. Further details are given in the respective wizard descriptions later in this

chapter.

Biacore T200 Software Handbook 28-9768-78 Edition AA 35

Application wizards 4

• The number of completed rows in the sample and control sample tables

determine the number of cycles that will be run in the assay. The rack

position requirements and the required volumes of common solutions

such as regeneration (Section 4.2.6) are calculated on the basis of the

number of samples that will be run.

• For some wizards, control samples are defined in a step in the dialog box

sequence. For others, the Control samples dialog is accessed through a

button in the Samples step.

• Sample details can be imported from an external file if this option is

enabled under Tools:Preferences. See Appendix A for details of import

formats and procedures.

4.2.5 System preparations

This dialog box specifies how the system will be prepared before the first cycle.

4 Application wizards

4.2 Common wizard components

36 Biacore T200 Software Handbook 28-9768-78 Edition AA

Prime before run

This option flushes the flow system with running buffer to make sure that all

buffer is fresh. You should generally prime the system before each run to ensure

fresh buffer throughout the flow system.

Normalize

This option adjusts the detector response to compensate for small variations in

reflectance characteristics between individual sensor chips. For best results,

you should normalize the detector whenever the chip is changed. You do not

need to run normalization if the same chip remains docked between runs.

Normalization injects BIAnormalizing solution (70% glycerol) over the surface: if

your ligand does not withstand exposure to this solution, normalize the detector

before you immobilize the ligand.

Temperature settings

The Analysis temperature is the temperature at the flow cell. If the specified

value differs from the current temperature, the system will wait at the beginning

of the run until the analysis temperature is stable at the new value. You can

choose to ignore temperature instability, but the response will drift as the

temperature stabilizes. The absolute response decreases by about 150 RU for a

1°C increase in temperature.

The Sample compartment temperature is the temperature in the sample

compartment. Equilibration of the sample compartment to a new temperature

will start when the run is started. The system will not wait for a stable sample

compartment temperature at the beginning of the run: samples equilibrate to

the analysis temperature during passage through the IFC, so that the sample

compartment temperature is not critical for the measured SPR response.

Note: Both analysis temperature and sample compartment temperature can be

set in advance with the Set Temperature option from the main Tools

menu (Section 2.3.6), to allow the temperature to equilibrate before

setting up the assay wizard.

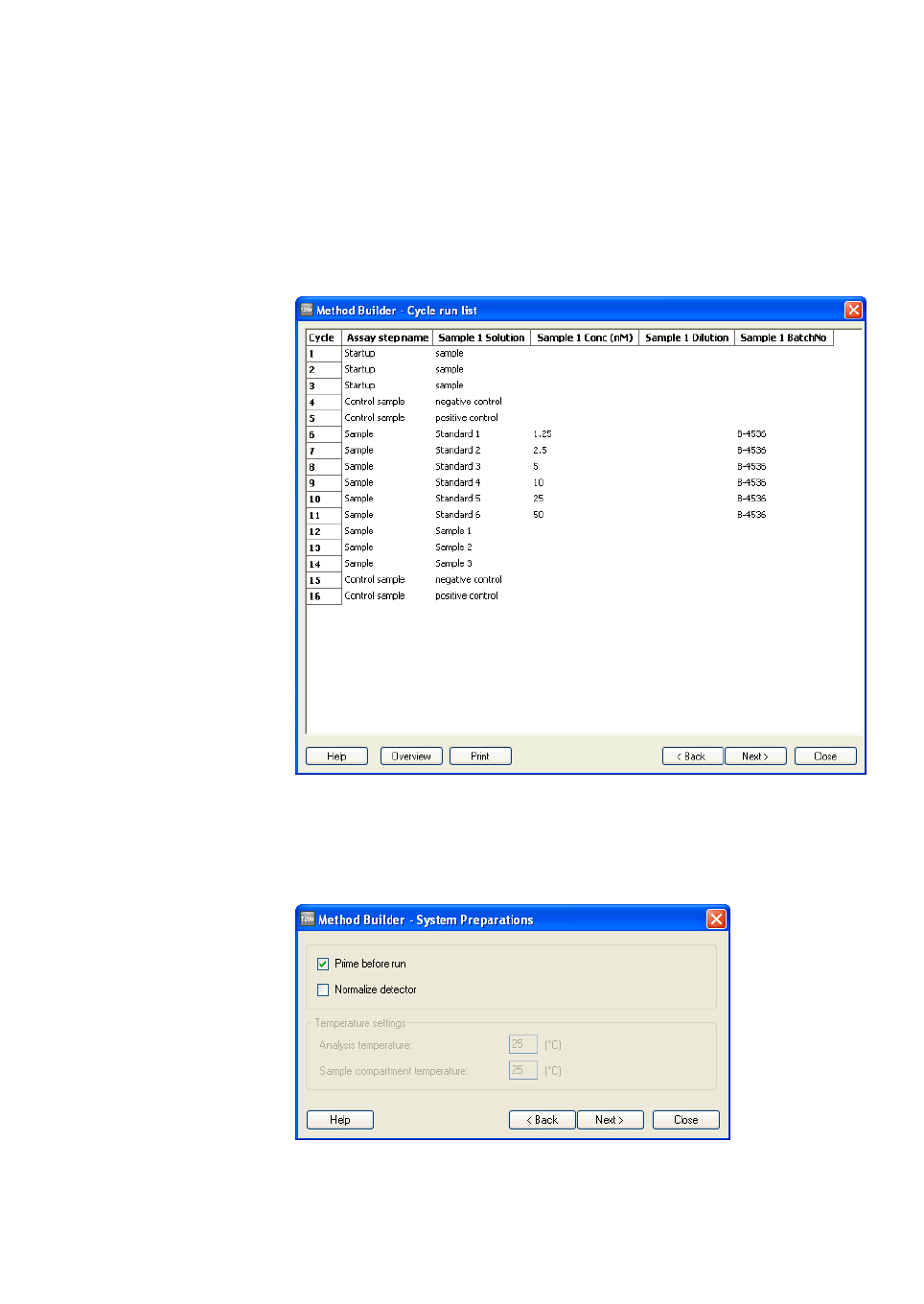

Cycle run list

Click Cycle Run List to display a preview of the cycles that will be run in the

assay.

Biacore T200 Software Handbook 28-9768-78 Edition AA 37

Application wizards 4

The Assay step name is generated automatically as a type identifier for each

cycle. Other keywords may also be generated according to the wizard purpose.

Keyword information is used in the Evaluation Software.

4.2.6 Rack positions

This dialog box shows where samples and reagents are to be placed in the

microplate and/or rack. Positions are color-coded by region according to

sample and reagent categories: you can change the color-coding in the

Automatic positioning dialog, accessed through the Menu button.

4 Application wizards

4.2 Common wizard components

38 Biacore T200 Software Handbook 28-9768-78 Edition AA

Use the pull-down lists above the respective illustrations to change the reagent

rack and microplate types. If change a rack or microplate type, all positions in

the affected rack or plate will be cleared and must be reassigned either

manually or automatically.

Positions are described by tool tips (hold the cursor on the position to display the

tool tip). Empty positions show the position capacity and dead volume. Used

positions show in addition the content name and the volume that will be used.

Note: The volumes listed in the table are minimum volumes. Use slightly larger

volumes if material is available to allow for slight variations in the dead

volume in microplates and vials.

You can change sample and reagent positions manually in two ways:

• Click on a sample or reagent in the sample plate and rack illustration and

drag it to a new (empty) position. You cannot drag to a position that does

not have sufficient capacity for the required volume of sample or reagent.

• Enter an unused position directly in the Position column in the table.

Positions can also be reorganized using the Automatic positioning dialog (see

below).

Menu functions

Use the Menu button to access additional functions for rack positioning.

Clear Positions

This option clears the entries in the Positions column for the selected rack or

plate.

Positions that are cleared must be reassigned before the run can be started. To

reassign positions one by one, select a row in the positioning table and click on

the required (empty) position in the illustration. To reassign all positions in one

operation, choose Default Positions or Automatic positioning from the menu.

Default Positions

This option restores all entries to default positioning. The default positioning is

determined from the type and volume of solution in combination with the

currently selected rack type. Choosing Default Positions overrides any changes

that have been made in the rack positions, even if the changed positions have

been saved in the wizard template.

Biacore T200 Software Handbook 28-9768-78 Edition AA 39

Application wizards 4

Automatic Positioning

This option controls the way samples and reagents are positioned

automatically. Samples and reagents are placed by region, and samples within

regions are kept together as far as possible.

Use the Move up and Move down buttons to change the order in which regions

are listed. Regions are placed in the specified rack or plate in the order listed, so

that changing the order of the table can change the automatic positioning of

samples and reagents.

Region This column lists the sample and reagent regions.

Color This option controls the display color for the region.

Orientation This column determines whether samples are arranged by

column (vertically in the rack and plate diagram) or row

(horizontally in the diagram).

Anchor This column determines the position for the first sample in the

region.

Rack This option controls whether the samples and reagents will be

placed in the reagent rack or the sample microplate. If Auto is

chosen, placement is decided on the basis of number and volume

of solutions in the region.

Vial size Use this option to determine the vial size for reagents. If Auto is

chosen, placement is decided on the basis of the volume of

solution.

Pooling This option allows you to combine solutions with the same name

into one position or to split combined solutions into separate

positions for each cycle. Choose Yes to pool solutions if suitable

vial positions are available, or No if you always want separate

positions for each cycle. Choose Auto to set the pooling

according to the default settings for the type of region.

Sort by Solutions within a region may be sorted by one or two

parameters.

4 Application wizards

4.2 Common wizard components

40 Biacore T200 Software Handbook 28-9768-78 Edition AA

Save Wizard Template/Save Wizard Template As

Saves the wizard template, with either the same or a different file name. The

corresponding function is also available for methods.

Custom Position Import

This option imports positioning information from an external source. The option

is only available if Enable custom position import is checked in

Tools:Preferences. Choosing the option first exports the rack positions table to

a temporary tab-separated text file which is processed by the import program

specified in the Tools:Preferences dialog. The output of the import program is

then imported to the Rack Positions table, replacing the existing positioning

information. See Appendix A for more details.

Simple Position Import

Imports positioning details from an external file. Details of the import settings

and file format are described in Appendix A.

Export Positions

Exports the data in the positioning table to a tab-separated text file. See

Appendix A for details of the exported file format.

Print Rack Positions

Prints a copy of the rack positions diagram and table.

Print Wizard Template/Print Method

Prints a copy of the currently open wizard template or method.

Biacore T200 Software Handbook 28-9768-78 Edition AA 41

Application wizards 4

4.2.7 Prepare Run protocol

This dialog box allows you to enter a run protocol to provide instructions to the

user when the run is started. The text in the Prepare Run Protocol is saved with

the wizard template. A suggested general protocol is provided.

Select text and use the controls at the top of the dialog box to control the

appearance (typeface, size and style) of the text.

The estimated run time and buffer requirement are shown at the bottom of the

dialog box. For all wizards except buffer scouting, only buffer A is used. For the

buffer scouting wizard (Section 4.7) and Method Builder-based runs

(Section 5.4), buffer names are shown in the Prepare Run Protocol dialog.

Notes: The estimated run time and buffer consumption are minimum values,

that do not include any time that cannot be predicted when the wizard is

set up. This includes time for temperature equilibration at the beginning

of the run or between cycles, for ligand injection in immobilization runs

using Aim for immobilized level (Section 4.5) and for conditional

statements (Section 5.6.1) in Method Builder-based runs.

The estimated buffer requirement includes a dead volume of at least

50 ml in the buffer bottle and is rounded up to the nearest 100 ml. The

actual consumption will often be considerably less than the estimate.

Make sure there is sufficient buffer in the bottle to allow for standby time

after the run.

The Menu button provides options for saving and printing the wizard template

(Section 4.2.6).

4 Application wizards

4.3 Wizard groups

42 Biacore T200 Software Handbook 28-9768-78 Edition AA

4.3 Wizard groups

The application wizards are organized into 5 groups:

• Surface preparation, covering immobilization pH scouting and

immobilization

• Assay development, covering regeneration scouting, buffer scouting and

surface performance tests

• Control experiments for kinetic measurements, covering tests for linked

reaction mechanisms and mass transfer limitation

• Assay wizards, covering kinetics/affinity, binding analysis, concentration

analysis and thermodynamics

• Immunogenicity, covering screening, confirmation and isotyping for

immunogenicity investigations.

4.4 Immobilization pH scouting

The Immobilization pH scouting wizard helps you to find the optimal pH for

immobilizing your ligand, by testing ligand pre-concentration at a range of pH

values. See the Biacore Sensor Surface Handbook for further details. The

injection sequence for immobilization pH scouting is fixed.

Step 1. Setup

Choose the flow path for the pH scouting. Immobilization pH scouting is

restricted to a single flow cell within a run. The sensor surface in the flow cell

should be unmodified.

Biacore T200 Software Handbook 28-9768-78 Edition AA 43

Application wizards 4

Enter the buffers and pH values to be used for scouting. The default list covers

sodium acetate buffers in the pH range 4 to 5.5, available as ready-to-use

solutions from GE Healthcare. Buffers will be tested in the order listed.

Note: The buffers listed here are buffers in which the ligand should be prepared.

They are not used as running buffers: you should use the same running

buffer for pH scouting as you intend to use during immobilization.

Step 2. Injection parameters

Enter the name of the ligand to be tested and the contact time and flow rate.

Recommended settings are a contact time of 120 seconds at 5 or 10 µl/min: you

may need to use a longer contact time if preconcentration of ligand on the

sensor surface proves to be slow.

The surface is washed with a “regeneration” injection at the end of each cycle to

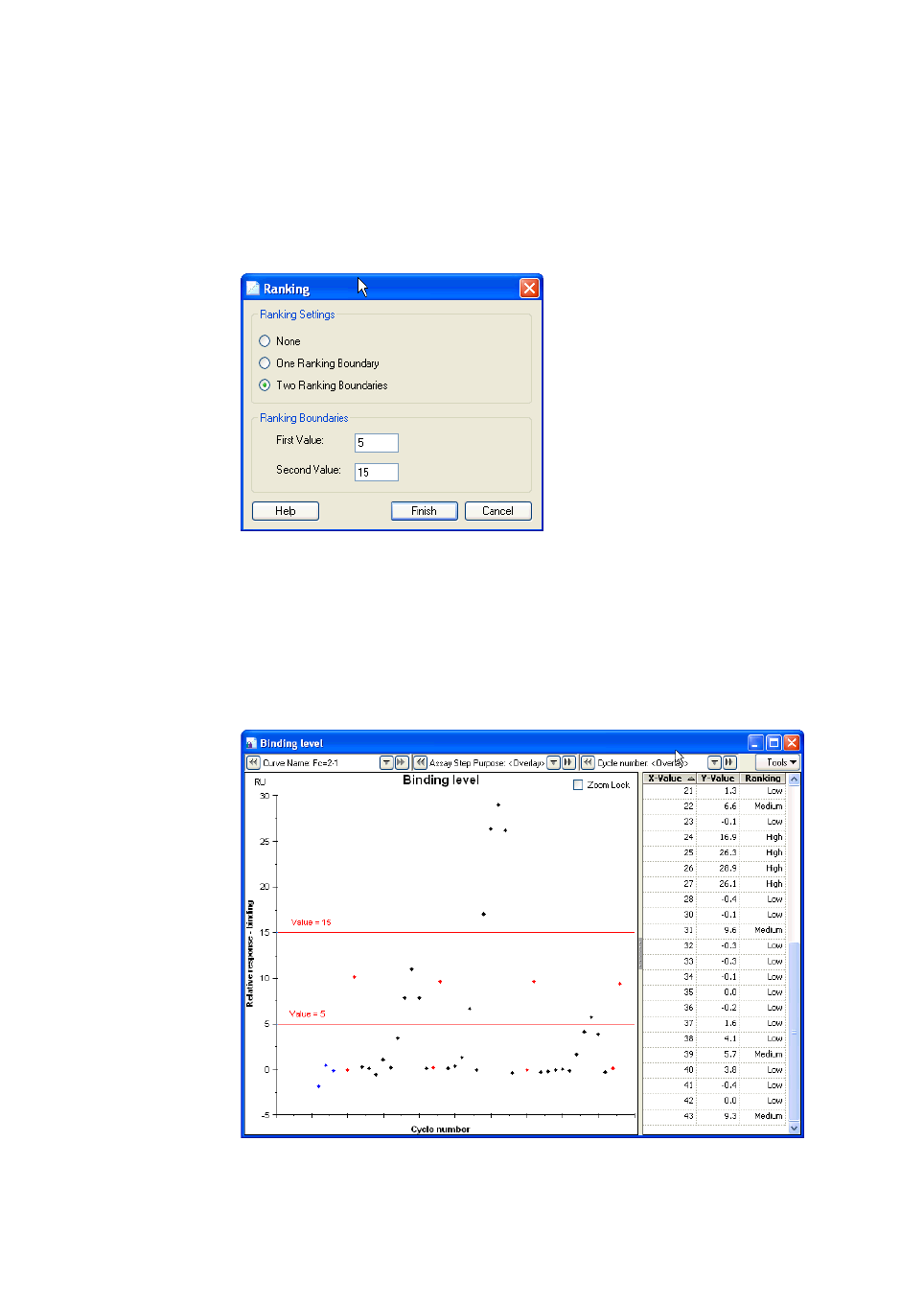

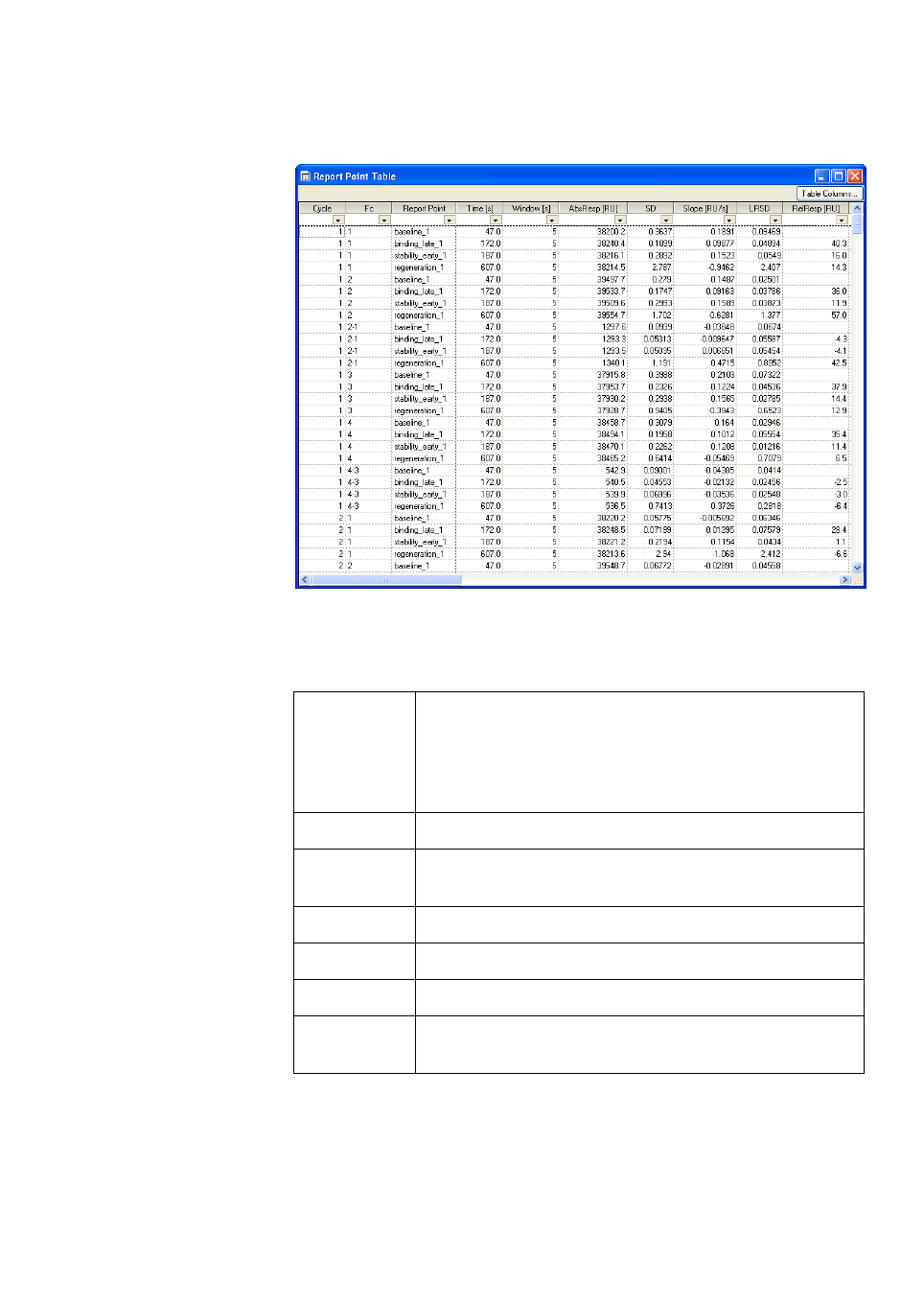

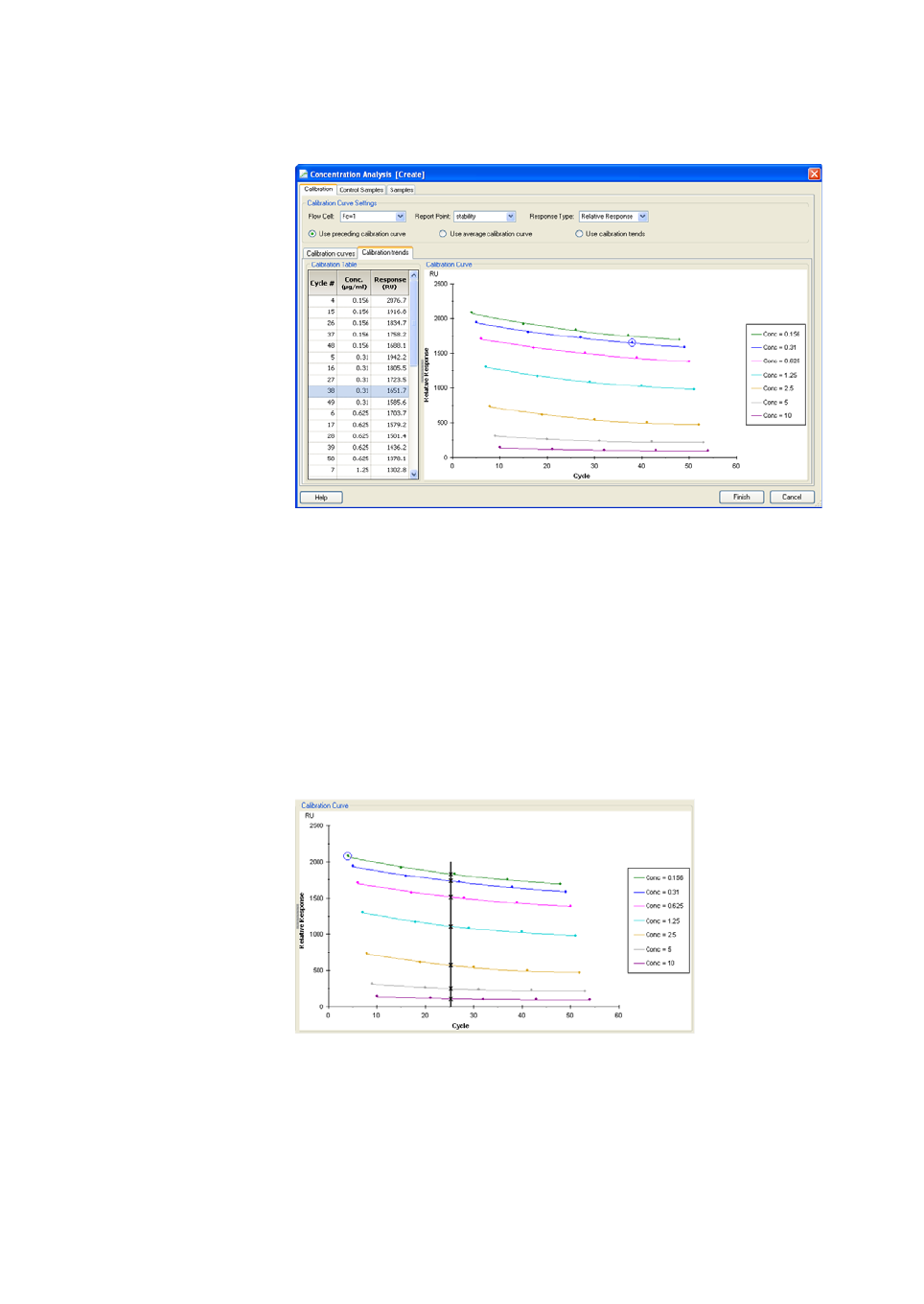

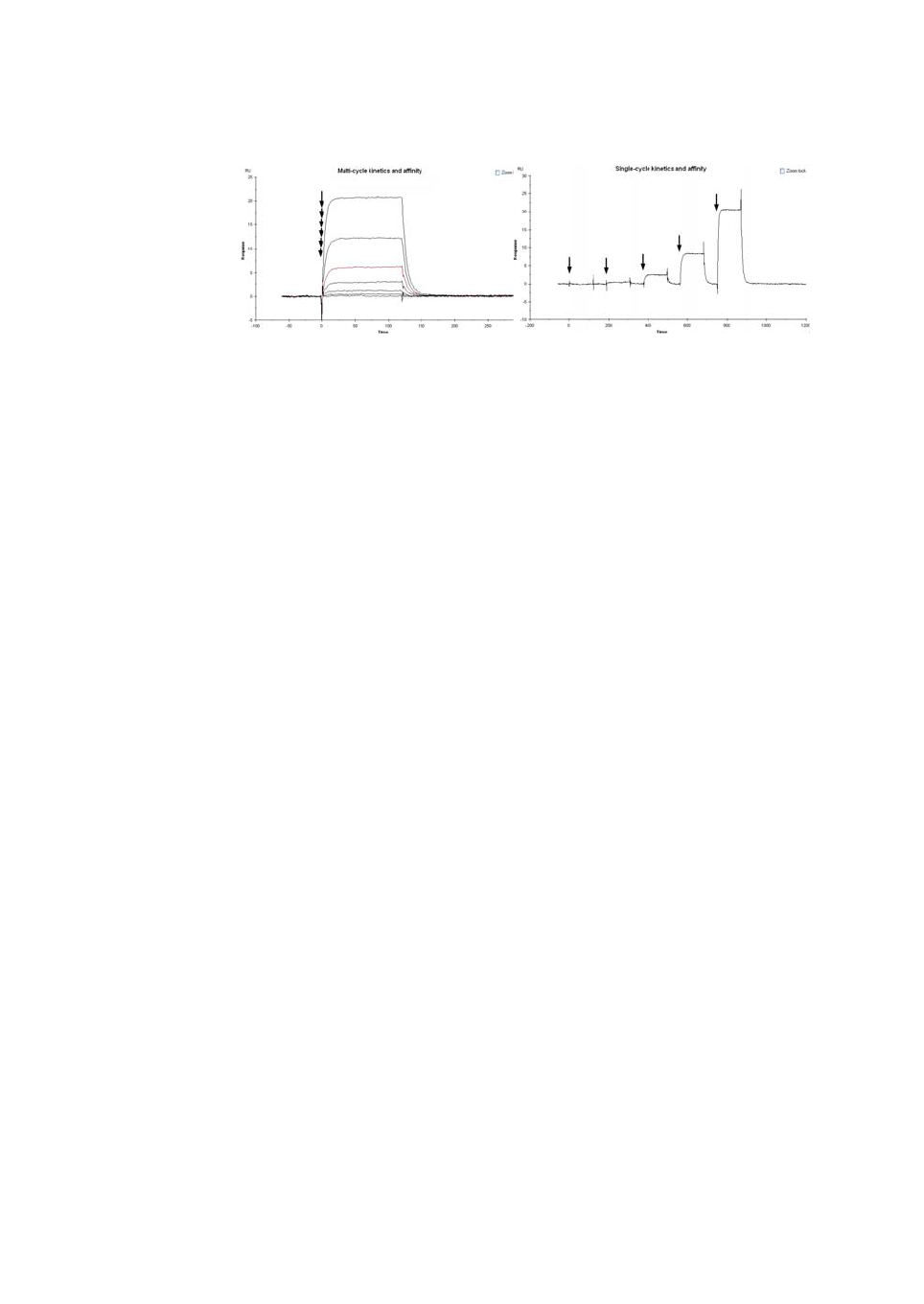

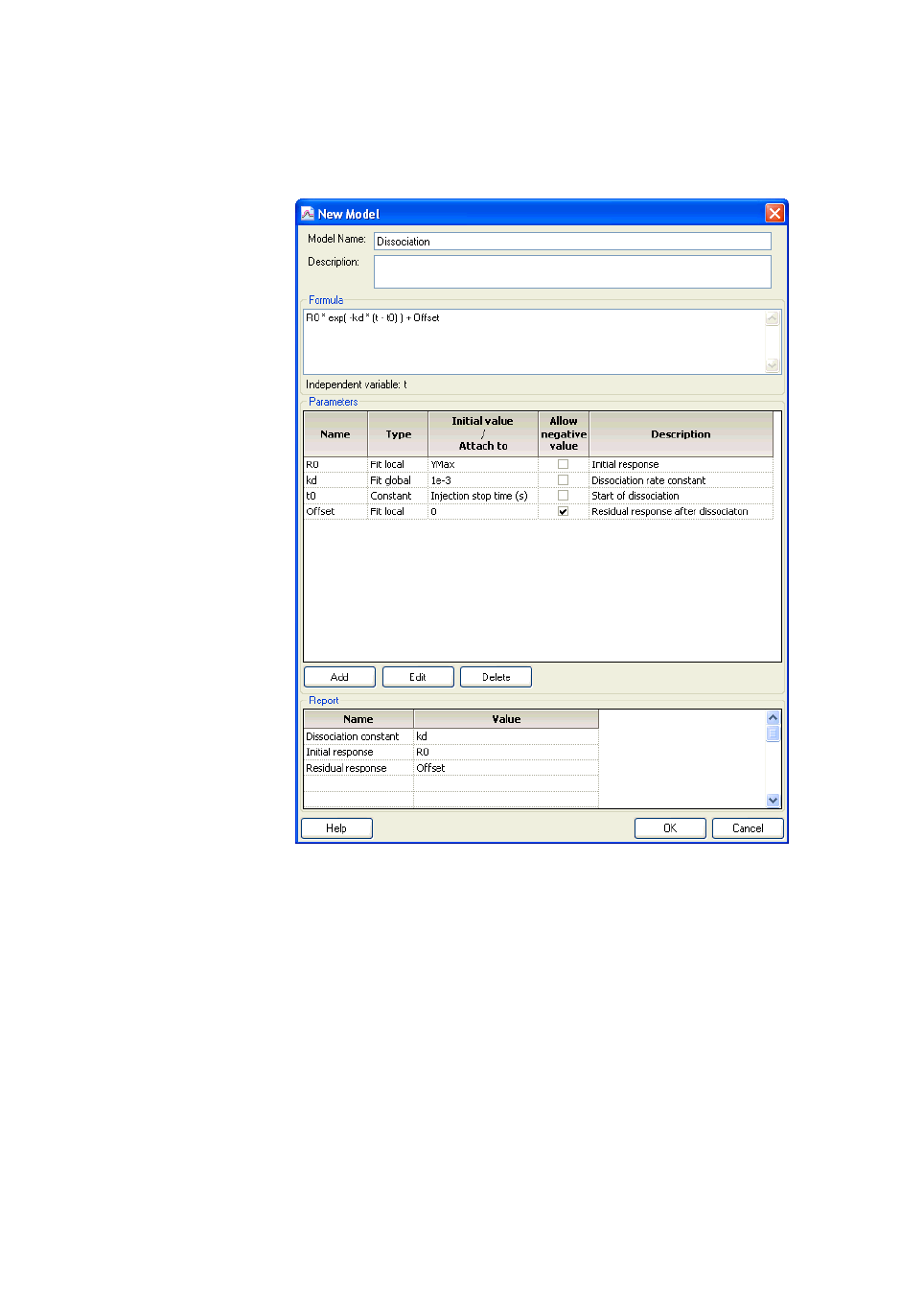

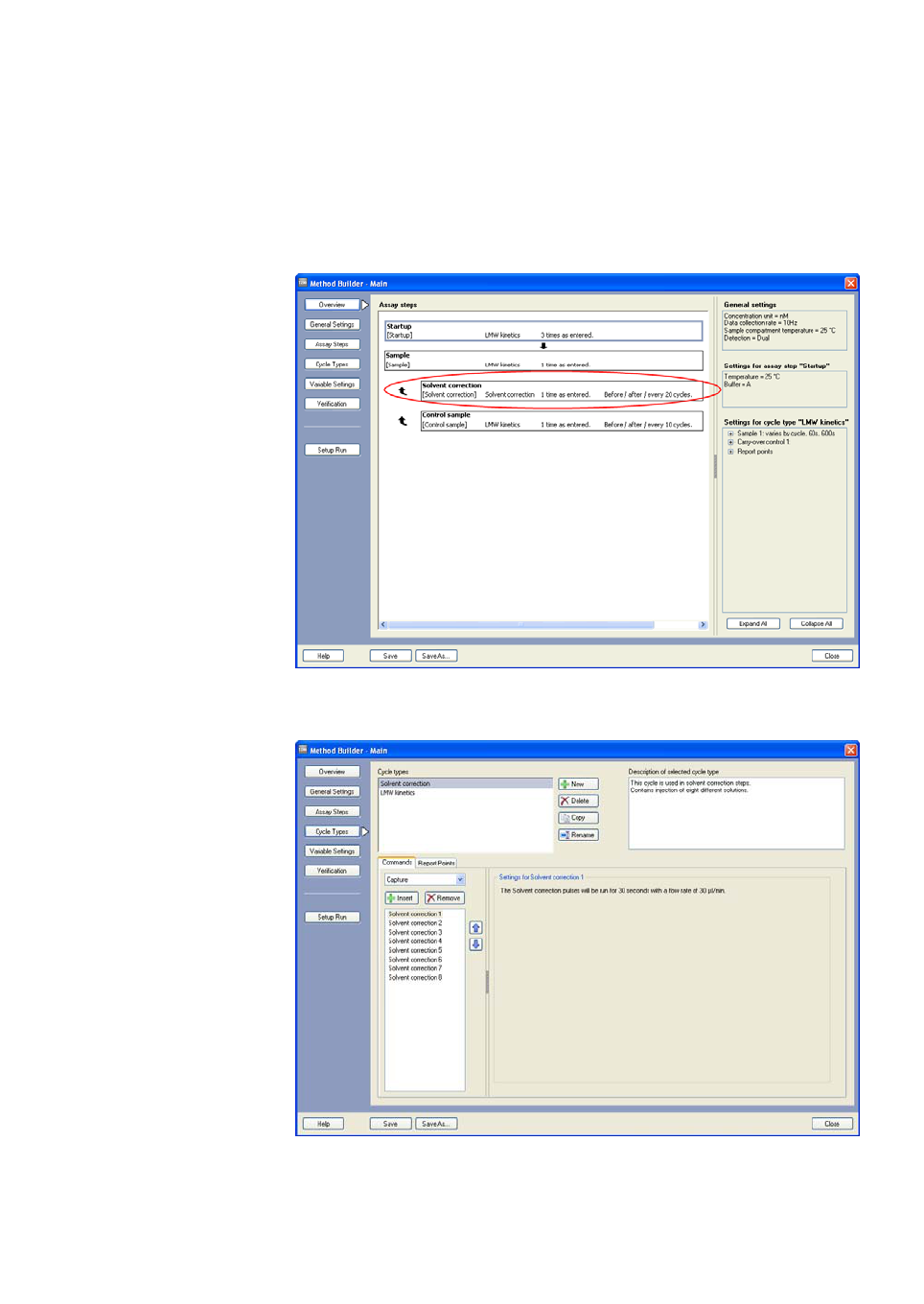

remove any ligand that might remain on the surface. The recommended